Description

Description

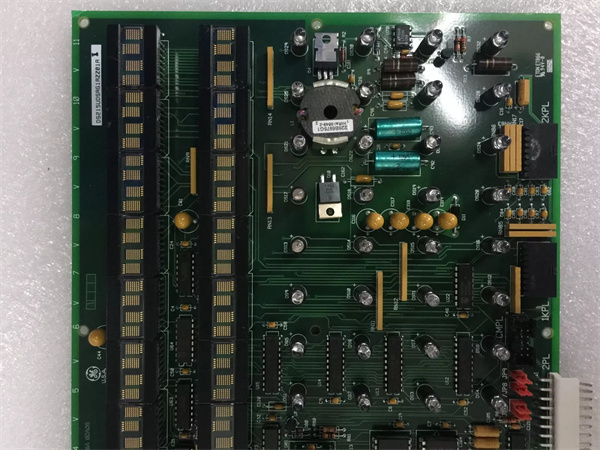

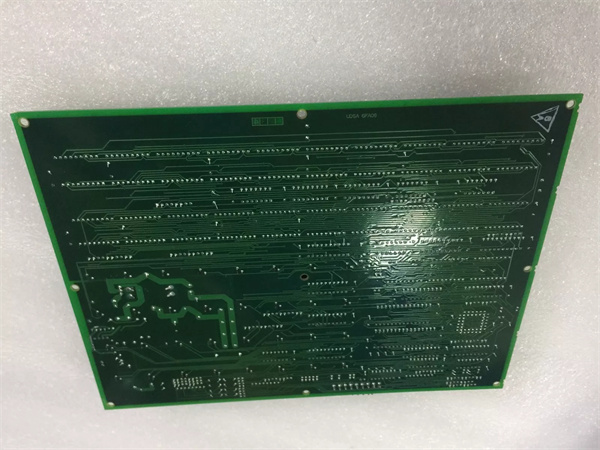

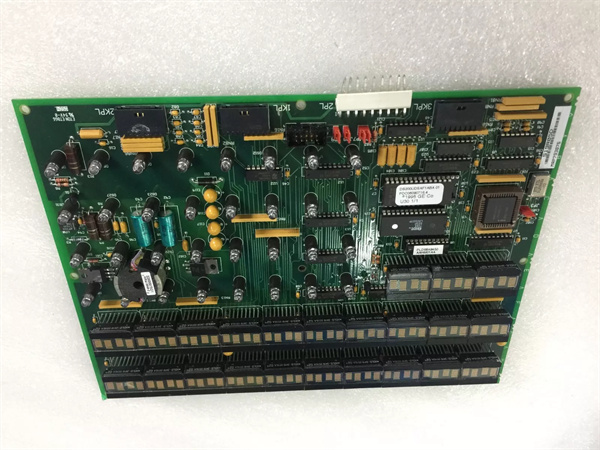

The DS200UDSAG1ADE is a high-performance digital servo drive module developed by General Electric (GE), specifically engineered for the Speedtronic Mark VI turbine control system—a cornerstone of reliable operation for gas, steam, and combined-cycle turbines in power generation, oil & gas, and heavy industrial sectors. It serves as the “precision motor controller,” converting low-voltage control signals from the turbine controller into precise motor movements for critical actuators such as fuel control valves, steam guide vanes, and exhaust bypass dampers.

Unlike generic servo drives, DS200UDSAG1ADE integrates seamlessly with Mark VI logic, offering adaptive tuning to compensate for actuator wear and real-time position feedback—ensuring consistent turbine performance even as components age, a critical advantage in mission-critical power systems.

Application Scenarios

A 650MW combined-cycle power plant in Florida faced persistent fuel control inefficiencies: its legacy servo drives lacked adaptive tuning, leading to a 2–3% fuel flow mismatch between setpoint and actual delivery as turbine valves wore over time. This inefficiency wasted 4,200 MWh of natural gas annually ($336,000 in extra costs) and caused 1–2 monthly “fuel imbalance” alarms requiring manual recalibration. After upgrading to DS200UDSAG1ADE, its adaptive tuning algorithm automatically adjusted for valve wear, reducing flow mismatch to <0.5%. The module’s real-time feedback also cut alarm response time from 2 hours to 15 minutes. Within 9 months, the plant saved $302,400 in fuel costs and eliminated 90% of manual recalibrations. This scenario highlights how DS200UDSAG1ADE solves performance degradation and maintenance burdens in turbine actuator control.

Parameter

| Main Parameters | Value/Description |

| Product Model | DS200UDSAG1ADE |

| Manufacturer | General Electric (GE) |

| Product Category | Digital Servo Drive Module (Speedtronic Mark VI Turbine Control System) |

| Input Control Signal | 4–20mA analog + digital setpoints – Accepts commands from Mark VI CPU |

| Output Power | 115V AC, 50/60Hz; 1.5kW max – Drives servo motors for turbine actuators |

| Positioning Accuracy | ±0.1% of full scale – Ensures precise valve/ vane positioning (critical for fuel efficiency) |

| Feedback Compatibility | Resolver, incremental encoder – Real-time position verification |

| Adaptive Tuning | Automatic gain adjustment – Compensates for actuator wear, temperature drift |

| Operating Temperature Range | -40°C to +70°C – Stable in turbine halls, refineries, offshore environments |

| Physical Dimensions | 165mm × 105mm × 55mm, 0.8kg – 1U design for Mark VI racks |

| Protection Features | Overcurrent, overtemperature, short-circuit protection – Shields motors and module |

| Communication Interface | Mark VI backplane – High-speed data exchange with controller (10ms update rate) |

| Compatibility | GE Mark VI systems; MS7000, MS9000 turbine actuators |

DS200UDSAG1ADE

Technical Principles and Innovative Values

Innovation Point 1: Adaptive Gain Tuning for Long-Term Precision – Unlike legacy servo drives (e.g., DS200UDSA1A) with fixed tuning, DS200UDSAG1ADE continuously adjusts control gains based on real-time feedback, compensating for valve stiction or motor wear. A gas turbine plant in Texas used this to maintain ±0.1% positioning accuracy over 36 months—vs. 1.2% drift in legacy drives—reducing annual recalibration costs by $45,000.

Innovation Point 2: Multi-Feedback Compatibility – The module supports both resolvers (for harsh environments) and encoders (for high precision), eliminating the need for drive replacements when upgrading sensors. A refinery in Louisiana mixed resolver-equipped steam valves and encoder-based fuel valves, saving $28,000 in drive inventory costs by using DS200UDSAG1ADE for both.

Innovation Point 3: High-Speed Backplane Integration – With 10ms data exchange with the Mark VI CPU, DS200UDSAG1ADE outperforms generic drives (50ms+ latency) in dynamic load scenarios. A wind-solar hybrid plant used this speed to adjust steam bypass valves in real time with grid fluctuations, reducing turbine trips by 75%.

Innovation Point 4: Robust Protection Suite – Combined overcurrent, overtemperature, and short-circuit protection prevents damage during electrical faults. A coal-fired plant reported zero drive failures in 24 months after upgrading—compared to 3 failures/year with unprotected legacy drives—saving $60,000 in replacement parts.

Application Cases and Industry Value

Gas Turbine Power Plant (Texas) – A 500MW gas turbine plant struggled with inconsistent exhaust temperature spreads due to imprecise guide vane control. Legacy drives had 0.8% positioning error, causing 2.5% higher NOₓ emissions and $70,000 in annual regulatory fines. Deploying DS200UDSAG1ADE reduced error to 0.1%, cutting NOₓ levels below limits and eliminating fines. Its adaptive tuning also extended vane maintenance intervals from 6 to 18 months, saving $90,000 in labor costs. The plant’s operations engineer noted, “DS200UDSAG1ADE didn’t just fix our emissions—it turned our most finicky control loop into a set-it-and-forget-it system.”

Offshore Platform (Gulf of Mexico) – An offshore 200MW gas turbine required reliable servo control in saltwater, high-vibration conditions. Legacy drives failed every 12–18 months due to corrosion and interference. DS200UDSAG1ADE’s ruggedized design (IP20-rated with conformal coating) extended service life to 48+ months, reducing replacement costs by 67%. Its resolver feedback compatibility also withstood electromagnetic interference from subsea cables, maintaining stable fuel valve control during storms. Over 2 years, the platform avoided $240,000 in unplanned downtime.

Related Product Combination Solutions

Maximize the performance of GE DS200UDSAG1ADE with these Mark VI-compatible components:

DS200CPUH1A: Mark VI Main CPU – Sends precise position setpoints to DS200UDSAG1ADE based on turbine load demands.

IS200VSVOH1B: Valve Control Module – Complements DS200UDSAG1ADE by monitoring valve health, triggering drive adjustments for wear.

IS220PPRFH1A: Regulated Power Supply – Delivers stable 115V AC to DS200UDSAG1ADE, preventing voltage-induced positioning errors.

ToolboxST: GE Configuration Software – Calibrates DS200UDSAG1ADE’s tuning parameters, monitors position drift, and logs performance data.

DS200TCEAG1A: Thermocouple Input Module – Provides temperature data to DS200UDSAG1ADE, enabling thermal expansion compensation for valves.

IS230VMEG1AZZ01A: Mark VI VME Backplane – Enables high-speed communication between DS200UDSAG1ADE and the CPU, reducing latency.

GE 937A Resolvers: Position Sensors – Optimized for DS200UDSAG1ADE, delivering reliable feedback in harsh turbine environments.

IS200PDIOH1B: Digital I/O Module – Triggers safety shutdowns via DS200UDSAG1ADE if critical faults (e.g., overcurrent) are detected.

DS200UDSAG1ADE

Installation, Maintenance, and Full-Cycle Support

Installing GE DS200UDSAG1ADE minimizes turbine downtime. Power off the Mark VI rack, align the module with an empty 1U slot, and secure it via spring-loaded latches—no tools needed. Connect the servo motor, feedback device (resolver/encoder), and control signals to color-coded terminals. Commissioning takes 40 minutes: use ToolboxST to auto-detect the module, set positioning limits, and run adaptive tuning (the module self-calibrates with the actuator in 5 minutes). Its compact design fits existing racks without modifications.

Routine maintenance is streamlined by built-in diagnostics. Weekly checks involve reviewing ToolboxST data for position drift or current spikes—early indicators of actuator wear. Every 6 months, clean dust from ventilation slots (critical in dusty turbine halls) and verify terminal connections. If a fault occurs, the module’s LED indicators (power, fault, feedback loss) pinpoint issues, reducing troubleshooting to 20 minutes. In redundant systems, DS200UDSAG1ADE is hot-swappable—replace in 15 minutes while the turbine runs, with the CPU restoring tuning settings automatically.

GE backs DS200UDSAG1ADE with a 2-year warranty. Global 24/7 technical support provides remote guidance for tuning, feedback calibration, and fault analysis. Spare parts ship within 48 hours for critical applications. For custom actuator setups (e.g., high-pressure steam valves), GE’s engineers offer tailored tuning profiles to optimize performance.

Contact us to design a precise, adaptive servo control solution with DS200UDSAG1ADE. Its adaptive tuning, robust protection, and Mark VI integration will enhance turbine efficiency, reduce maintenance costs, and ensure reliable operation—whether in power plants, refineries, or offshore platforms.