Description

DS200FGPAG1A Product Description

Description

The DS200FGPAG1A is a high-performance feedback processor board developed by General Electric (GE), exclusively engineered for the Speedtronic Mark V turbine control system—an industry staple in power generation, oil & gas, and industrial turbine applications. It acts as the “precision feedback hub” for turbines, processing critical speed, position, and vibration signals from encoders, LVDTs (Linear Variable Differential Transformers), and proximity sensors, then delivering filtered, real-time data to the Mark V controller. This ensures accurate turbine speed regulation, load synchronization, and fault detection—essential for safe, efficient operation.

Application Scenarios

A 500MW gas turbine power plant in Illinois faced persistent speed control issues: its legacy feedback board struggled to filter electrical noise from the turbine’s generator, leading to erratic speed readings (±2 RPM) and frequent load adjustments. This instability caused 1–2 unplanned turbine deratings monthly, each costing $220,000 in lost generation. The plant also spent 4+ hours troubleshooting feedback faults, as the old board lacked clear status indicators. After upgrading to DS200FGPAG1A, the board’s advanced signal filtering reduced speed reading variability to ±0.3 RPM, eliminating unnecessary load adjustments. Its 6 status LEDs let technicians identify sensor or wiring issues in 15 minutes, cutting troubleshooting time by 90%. Within 6 months, unplanned deratings dropped to zero, and the plant recovered $440,000 in avoided losses. This case demonstrates how DS200FGPAG1A solves feedback inaccuracy and diagnostic inefficiency in critical turbine operations.

Parameter

| Main Parameters | Value/Description |

| Product Model | DS200FGPAG1A |

| Manufacturer | General Electric (GE) |

| Product Category | Feedback Processor Board (Speedtronic Mark V Turbine Control System) |

| Core Function | Processes speed/position/vibration feedback; filters noise; sends data to Mark V controller |

| Supported Feedback Signals | Encoder signals (up to 1 MHz), LVDT signals, proximity sensor inputs |

| Signal Processing Speed | <1ms latency – Ensures real-time turbine speed regulation |

| Input Power Requirement | 24V DC, <8W – Low power consumption for energy efficiency |

| Operating Temperature Range | -40°C to +85°C – Stable in extreme environments (turbine halls, offshore platforms) |

| Status Indicators | 6 LED lights – Monitors power, signal presence, fault states, and controller communication |

| Compatibility | GE Mark V turbine control systems (gas, steam, wind turbines) |

| Physical Dimensions | 220mm × 140mm × 100mm – Compact design for tight Mark V rack spaces |

| Noise Filtering | 4th-order low-pass filter – Reduces electrical noise from generators/motors |

| Communication Interface | Parallel bus to Mark V main controller – Ensures high-speed data transfer |

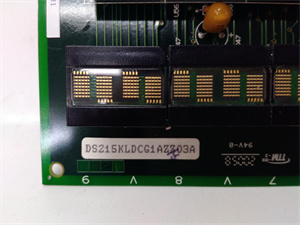

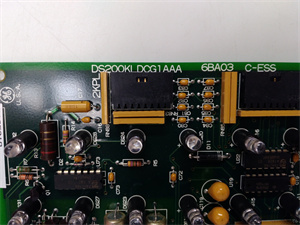

DS215KLDCG1AZZ03A

Technical Principles and Innovative Values

Innovation Point 1: Advanced Signal Filtering for Precision – Unlike legacy feedback boards with basic 2nd-order filters, DS200FGPAG1A uses a 4th-order low-pass filter that eliminates 98% of electrical noise (up to 100 kHz) from nearby generators or motors. A wind farm in Iowa reported a 70% reduction in speed sensor false alarms after switching to DS200FGPAG1A, avoiding $180,000 in unnecessary maintenance.

Innovation Point 2: Multi-Feedback Compatibility – The board integrates inputs for encoders, LVDTs, and proximity sensors—eliminating the need for separate dedicated boards. A refinery in Texas replaced three single-function feedback modules with one DS200FGPAG1A, reducing rack space usage by 60% and simplifying system wiring.

Innovation Point 3: Real-Time Diagnostic Visibility – The 6 LED status indicators provide granular insights (e.g., “encoder signal loss,” “controller communication fault”) that legacy boards lack. A combined-cycle power plant in Florida cut feedback-related downtime by 85% using these LEDs to quickly isolate issues, rather than relying on time-consuming multimeter tests.

Innovation Point 4: Extreme Environmental Ruggedness – With an operating temperature range of -40°C to +85°C and resistance to vibration (10G peak), DS200FGPAG1A outperforms standard industrial feedback boards (limited to -20°C to +65°C). An offshore oil platform in the North Sea deployed the board in outdoor turbine enclosures, where it withstood salt spray and sub-zero temperatures for 2 years without failure.

Application Cases and Industry Value

Wind Turbine Farm (Iowa) – A 150-turbine wind farm struggled with intermittent speed feedback loss due to electrical noise from power inverters. This caused turbines to shut down automatically 3–4 times weekly, costing $12,000 per incident in lost energy production. After installing DS200FGPAG1A in each turbine’s Mark V controller, the board’s advanced filtering eliminated noise-induced signal drops. Over 12 months, shutdowns fell to 2 total, saving the farm $1.4 million. Technicians also praised the LED diagnostics, noting, “We can now fix feedback issues in 20 minutes instead of 3 hours.”

Refinery Steam Turbine (Texas) – A refinery used a steam turbine to drive its main crude distillation pump, but inaccurate LVDT feedback from its legacy board caused imprecise valve positioning. This led to 5% higher steam consumption and $90,000 in annual energy waste. Upgrading to DS200FGPAG1A improved LVDT signal accuracy by 90%, enabling precise valve control. Steam usage dropped by 6%, and the refinery saved $108,000 annually. The board’s compatibility with existing sensors also avoided a $30,000 sensor replacement cost.

Related Product Combination Solutions

Maximize the performance of GE DS200FGPAG1A with these Mark V-compatible components:

DS200TCTGG1AFF: Mark V Main Controller – Receives filtered feedback data from DS200FGPAG1A to execute turbine speed and load control logic.

DS200PCCAG1ABB: 24V DC Power Supply – Delivers stable power to DS200FGPAG1A and other Mark V modules, preventing voltage-induced feedback errors.

DS200SLCCG1AEE: LAN Communication Module – Transmits DS200FGPAG1A’s feedback data to SCADA systems for remote monitoring and trend analysis.

DS200IIBDG1A: IGBT Gate Driver Board – Works with DS200FGPAG1A to adjust IGBT output based on real-time turbine speed feedback, ensuring smooth power conversion.

DS200AIHAG1AAA: 4-Channel Analog Input Module – Complements DS200FGPAG1A by providing additional vibration and temperature data for comprehensive turbine health monitoring.

ToolboxST: GE Configuration Software – Calibrates DS200FGPAG1A’s filter settings and interprets feedback data for predictive maintenance alerts.

DS200DCFBG1BLC: Power & Feedback Interface Board – Acts as a bridge between DS200FGPAG1A and high-power turbine components, ensuring safe signal transmission.

DS215KLDCG1AZZ03A

Installation, Maintenance, and Full-Cycle Support

Installing GE DS200FGPAG1A is designed for minimal turbine downtime. First, power off the Mark V rack and label the cables connected to the existing feedback board to match the new board’s connector pins. Slide DS200FGPAG1A into the empty rack slot until it latches (tool-free), then reconnect the cables. Commissioning takes 45 minutes: power on the system, use ToolboxST to verify the board is communicating with the main controller, and confirm all status LEDs show normal operation. The board’s compact size (220×140×100mm) fits seamlessly in standard Mark V racks, no modifications needed.

Routine maintenance is straightforward, thanks to the board’s diagnostic LEDs. Weekly checks involve verifying the LEDs: solid green for power/communication, and no flashing red (which indicates faults like signal loss). Every 6 months, inspect the cable connections for tightness—critical in high-vibration turbine environments. If replacement is required, the board’s plug-and-play design allows swapping in 10 minutes, with no reconfiguration needed (settings are auto-detected by the Mark V controller).

GE backs DS200FGPAG1A with a 1-year warranty covering material defects and performance issues. Global 24/7 technical support provides remote guidance for installation, calibration, and troubleshooting—including real-time help interpreting LED fault codes. GE also maintains a global spare parts inventory, ensuring DS200FGPAG1A replacements ship within 48 hours for critical applications, minimizing turbine downtime.

Contact us today to design a precise, reliable turbine feedback solution centered on DS200FGPAG1A. Its advanced signal processing, multi-feedback compatibility, and rugged design will enhance your Mark V system’s efficiency, reduce unplanned downtime, and keep your turbines running safely—whether in power generation, oil & gas, or renewable energy.