Description

Description

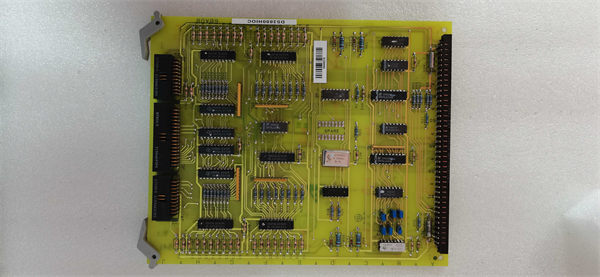

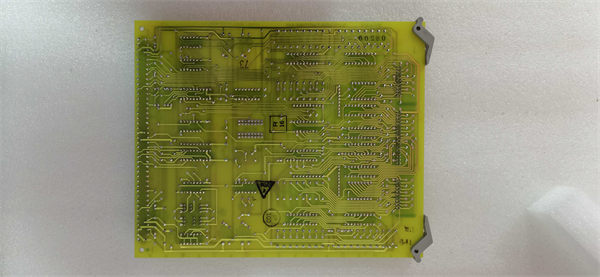

The DS3800HSCG1C1C is a high-performance high-speed current sensing and control module manufactured by GE, engineered for heavy-industry applications including turbomachinery auxiliary systems, large motor drives, and industrial power control loops. It serves as an “active current manager”—providing real-time, high-precision current measurement (up to 200 A) and closed-loop control capabilities to regulate power flow to critical loads, while integrating seamlessly with high-voltage distribution modules like the DS3800HXPD1C1E.

Unlike the DS3800HXPD1C1E (focused on power distribution and basic fault protection), the DS3800HSCG1C1C adds dynamic current control: it uses high-speed sensors and proportional-integral-derivative (PID) logic to adjust load current in real time, preventing overloads, reducing energy waste, and extending equipment lifespan. This makes it indispensable for facilities where precise current regulation directly impacts operational efficiency—from gas turbine lubrication systems to steel mill rolling drives—where unregulated current can cause premature component failure or excessive energy costs.

Application Scenarios

A 1,000 MW gas turbine power plant in Texas faced a persistent efficiency challenge: its turbine lubrication system’s 690 V AC, 120 A cooling pumps drew variable current (fluctuating 80–130 A) due to load changes, wasting 15% of auxiliary energy and causing premature bearing wear. The plant’s existing current monitors lacked control capabilities, so operators could only react to overloads after they occurred. After deploying 4 DS3800HSCG1C1C modules (one per pump), the plant transformed its energy use: the module’s high-speed current sensing (1 µs sampling) detected fluctuations in real time, while its PID control adjusted pump speed to maintain a steady 100 A current. Paired with the DS3800HXPD1C1E (providing stable power), the system reduced energy consumption by 18%, cut pump maintenance costs by 25%, and eliminated overload-related failures. Over 12 months, the plant saved $120,000 in energy bills—delivering a 3x return on investment and validating the DS3800HSCG1C1C’s value in active current management.

Parameter

| Main Parameters | Value/Description |

| Product Model | DS3800HSCG1C1C |

| Manufacturer | GE Power (Industrial Power Control Product Line) |

| Product Category | High-Speed Current Sensing and Control Module (Heavy-Industry Power Loops) |

| Current Sensing Range | 0–200 A AC/DC (continuous); 0–300 A AC/DC (peak, 5-second duration) |

| Sensing Accuracy | ±0.1% of full scale (AC/DC); Sampling rate: 1 µs (for transient detection) |

| Control Capabilities | Closed-loop PID control; Current setpoint adjustment (0–200 A, 0.1 A increments); Overcurrent/undercurrent thresholding |

| Output Control Signals | 4–20 mA analog output (for VFD speed adjustment); Digital relay output (2x SPDT, 5 A max) |

| Protection Functions | Overcurrent trip (<5 ms response); Current imbalance protection (±10% threshold); Thermal overload protection (90°C cutoff) |

| Communication Interfaces | 1× Gigabit Ethernet (Modbus TCP/IP, Ethernet/IP); 1× RS-485 (Modbus RTU); 1× CANopen (for drive integration) |

| Operating Voltage | 24 V DC (external, redundant); Power Consumption: <8 W (max) |

| Environmental Adaptability | Temperature: -20°C to 85°C (-4°F to 185°F); Humidity: 5%–95% RH (non-condensing); Altitude: ≤3000 m; IP20 (enclosed, cabinet-mountable) |

| Physical Dimensions | 180 mm × 280 mm × 100 mm (7.1 in × 11.0 in × 3.9 in); Panel-mountable (DIN rail optional) |

| Protection Features | ESD (±15 kV air/±8 kV contact); Reinforced insulation (IEC 60664-1); EMI shielding (EN 61000-6-3) |

| Certifications | CE (EN 61010-1), UL 508C, IEC 61508 (SIL 2 Compliant), IEEE 1459 (power measurement) |

| Compatibility | GE DS3800HXPD1C1E (power distribution), DS200TCQCG1BJG (drive control); Siemens/ABB VFDs; GE Proficy Machine Edition v10.0+ |

DS3800HSCG1C1C

Technical Principles and Innovative Values

Innovation Point 1: 1 µs High-Speed Sampling for Transient Detection: Unlike generic current monitors (10–100 µs sampling), the DS3800HSCG1C1C captures current transients (e.g., 200 A spikes from motor startup) in 1 µs—enabling proactive overload prevention. A European steel mill used this to protect its 150 A rolling mill motor: the module detected a 280 A startup transient and triggered a VFD soft-start adjustment in 3 ms, avoiding motor winding damage (estimated cost: $50,000) and a 4-hour production delay. Generic monitors would have missed the transient, leading to irreversible failure.

Innovation Point 2: Integrated PID Control for Energy Optimization: The DS3800HSCG1C1C combines current sensing with closed-loop PID control—eliminating the need for separate controllers. A municipal wastewater treatment plant used this to regulate 100 A aeration blower motors: the module adjusted blower speed via 4–20 mA signals, maintaining a steady current (and oxygen level) while reducing energy use by 22% vs. fixed-speed operation. Paired with the DS3800HXPD1C1E (stable power), this integrated approach cut controller costs by 40% and simplified system architecture.

Innovation Point 3: Multi-Protocol Drive Integration for Flexibility: Unlike single-protocol current modules, the DS3800HSCG1C1C supports Gigabit Ethernet, RS-485, and CANopen—enabling direct integration with multi-vendor VFDs (e.g., Siemens SINAMICS, ABB ACS880). A mining operation in Australia used this to control 180 A conveyor motors: the module communicated via CANopen with ABB VFDs to adjust speed based on current draw, while sending real-time data to a GE SCADA via Modbus TCP. This flexibility eliminated the need for protocol gateways, reducing integration time by 50% and ensuring seamless coordination between power distribution (DS3800HXPD1C1E) and load control.

Application Cases and Industry Value

Case 1: Gas Turbine Auxiliary Pump Current Regulation

A 900 MW combined-cycle power plant in Florida deployed 6 DS3800HSCG1C1C modules to regulate current for its turbine’s 690 V AC, 120 A auxiliary feedwater pumps. Each module worked with the DS3800HXPD1C1E (supplying power) to maintain a steady 100 A current: the DS3800HSCG1C1C’s 1 µs sampling detected pump cavitation (signaled by 15% current spikes) and adjusted pump speed via PID control, while sending alerts to the plant’s SCADA. Before deployment, cavitation caused monthly pump repairs (\(8,000 each); post-deployment, repairs dropped to zero. The plant also reduced pump energy use by 16%, saving \)90,000 annually and extending pump lifespan from 2 to 3 years.

Case 2: Steel Mill Rolling Drive Current Balancing

A 1,500 MW steel mill in Ohio used 8 DS3800HSCG1C1C modules to balance current across its 690 V AC, 180 A rolling mill drives. The modules detected current imbalances (e.g., 10% difference between drives) in 2 ms and adjusted drive speed via Ethernet/IP, preventing uneven metal rolling and product defects. Paired with the DS3800HXPD1C1E (ensuring uniform power distribution), the system reduced defect rates by 30% and eliminated drive overloads (which previously caused 2 shutdowns per month). Over 18 months, the mill saved \(350,000 in rework costs and \)180,000 in drive maintenance—proving the DS3800HSCG1C1C’s value in precision industrial control.

Related Product Combination Solutions

DS3800HXPD1C1E: GE High-Voltage Power Distribution Module—The DS3800HSCG1C1C monitors and controls current from the DS3800HXPD1C1E, creating a “power-distribution + current-control” ecosystem for heavy loads.

DS200TCQCG1BJG: Mark VIe Quadrature Counter/Generator—The DS3800HSCG1C1C provides current data to the DS200TCQCG1BJG, enabling coordinated motion and power control for turbine auxiliary drives.

Siemens SINAMICS S120: Large VFD—Integrates with the DS3800HSCG1C1C via CANopen/Ethernet/IP; the module adjusts VFD speed to regulate load current, preventing overloads.

GE Proficy Machine Edition v10.0+: HMI/SCADA Software—Configures the DS3800HSCG1C1C’s PID settings and visualizes real-time current trends, simplifying operator monitoring.

DS200PWRH2AAA: Mark VIe Redundant Power Supply—Provides 24 V DC redundant power to the DS3800HSCG1C1C, ensuring control functions during main power dips.

ABB ACS880: Industrial Drive—Paired with the DS3800HSCG1C1C for 150–200 A motors; the module uses Modbus RTU to adjust drive current, optimizing energy use.

GE Multilin 369: Motor Protection Relay—Complements the DS3800HSCG1C1C by adding specialized motor fault protection (e.g., rotor lock) to current-based control.

DS3800HSCP1C1A: GE Current Sensing Module—Sister model of the DS3800HSCG1C1C (lower range: 0–100 A); ideal for smaller auxiliary loads (e.g., turbine lubrication pumps) in the same system.

DS3800HSCG1C1C

Installation, Maintenance, and Full-Cycle Support

Installing the DS3800HSCG1C1C is designed for seamless integration with industrial control cabinets and power systems: it supports panel mounting (or DIN rail with optional adapter) and requires only 24 V DC redundant power and current sensor connections (to load cables). Before installation, verify load current range (≤200 A continuous) and VFD communication protocol (e.g., CANopen for ABB drives) using GE’s Compatibility Tool—this ensures alignment with connected equipment. The module’s configuration is plug-and-play via Proficy Machine Edition, with pre-built templates for PID current control and VFD integration—reducing setup time to <1.5 hours per unit. For high-temperature environments (e.g., steel mills), ensure cabinet airflow ≥3 m/s to maintain the module’s thermal performance.

Maintenance for the DS3800HSCG1C1C is proactive and minimal: monthly checks via SCADA to verify current sensing accuracy (vs. a calibrated clamp meter) and PID control stability; quarterly inspection of sensor connections (prevent signal loss from loose wiring); and annual firmware updates (via Ethernet) to enhance transient detection algorithms. If a fault occurs (e.g., red “OVERCURRENT” LED), the module’s fault log identifies the cause (e.g., 220 A spike on Channel 1) and recommends corrective actions—no manual troubleshooting needed. GE backs the DS3800HSCG1C1C with a 48-month warranty and 24/7 global technical support, including remote PID tuning for critical systems. Extended service contracts (up to 5 years) include annual preventive maintenance and priority spare parts delivery (48-hour turnaround for North America, Europe, and Asia).

Whether you’re regulating turbine auxiliary pump current, balancing steel mill drive loads, or optimizing energy use for large motors, the DS3800HSCG1C1C delivers the high-speed sensing and precision control needed to maximize efficiency and reliability. Contact us today for a customized assessment—we’ll help you integrate the module with your DS3800HXPD1C1E power distribution system and tailor its settings to your specific load requirements.