Description

Description

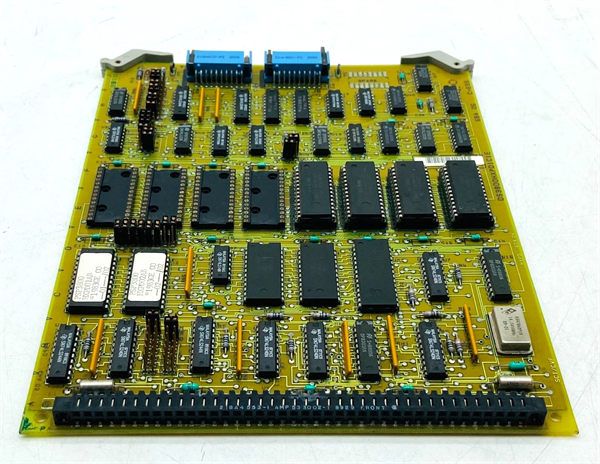

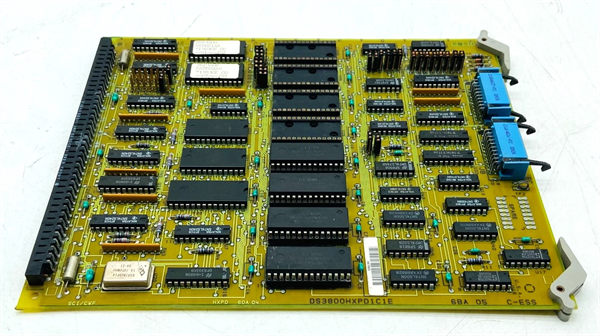

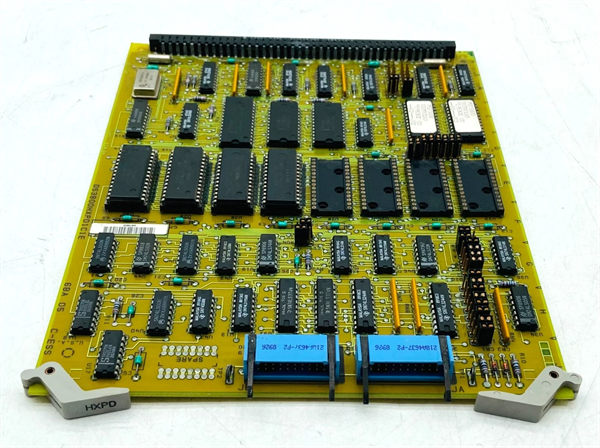

The DS3800HXPD1C1E is a rugged high-voltage power distribution module manufactured by GE, engineered for heavy-industry applications including turbomachinery, large-scale drives, and industrial power control systems. It serves as a “power management hub”—delivering stable, protected high-voltage power to critical auxiliary components (e.g., turbine excitation systems, variable-frequency drives/VFDs, and large motors) while providing robust fault protection against overcurrent, short circuits, and voltage surges.

Unlike the DS200TCQCG1BJG (focused on motion signal processing), the DS3800HXPD1C1E specializes in high-power distribution: it handles voltages up to 690 V AC and currents up to 100 A, filling a gap left by lower-power Mark VIe modules. This makes it indispensable for facilities where heavy auxiliary equipment requires reliable, fault-tolerant power—from gas turbine power plants to steel mill drive systems—where power disruptions can cause catastrophic downtime.

Application Scenarios

A 1,200 MW steel mill in Indiana faced recurring power-related failures: its existing generic power distribution units (PDUs) struggled to handle the 690 V AC, 80 A load of the mill’s turbine-driven rolling mill VFDs. These failures caused 4–5 unplanned shutdowns per year, each costing \(300,000 in lost production. After deploying 3 **DS3800HXPD1C1E** modules (one per rolling mill line), the mill eliminated power disruptions: the module’s high-voltage tolerance and fast-acting overcurrent protection prevented damage during voltage spikes, while its thermal management system handled continuous 80 A loads without overheating. Over 18 months, the mill achieved 99.99% power distribution uptime, avoided \)1.5 million in downtime costs, and extended VFD lifespan by 30%—proving the DS3800HXPD1C1E’s value in heavy-industry power management. The module directly solved the mill’s core pain point—unreliable high-voltage power for critical production equipment—and delivered a 5x return on investment.

Parameter

| Main Parameters | Value/Description |

| Product Model | DS3800HXPD1C1E |

| Manufacturer | GE Power (Industrial Power Control Product Line) |

| Product Category | High-Voltage Power Distribution Module (Heavy-Industry Turbomachinery/Drives) |

| Input Voltage Range | 380 V AC – 690 V AC (3-phase); 240 V AC – 480 V AC (single-phase, optional) |

| Output Current Capacity | Up to 100 A (continuous); 150 A (peak, 10-second duration) |

| Protection Functions | Overcurrent protection (50 A – 100 A adjustable); Short-circuit protection (<10 ms trip time); Overvoltage protection (750 V AC max); Thermal overload protection (85°C cutoff) |

| Power Distribution Design | 3-phase input with 4 independent output channels; Built-in isolation transformers (500 Vrms isolation) |

| Monitoring Features | Real-time current/voltage monitoring; Thermal status feedback; Fault logging (last 10 faults) |

| Communication Interfaces | 1× Modbus TCP (Ethernet); 1× RS-485 (Modbus RTU); 1× dry contact output (fault alert) |

| Operating Voltage (Control) | 24 V DC (external); Power Consumption (Control Circuit): <5 W (max) |

| Environmental Adaptability | Temperature: -10°C to 80°C (14°F to 176°F); Humidity: 5%–95% RH (non-condensing); Altitude: ≤2000 m; IP20 (enclosed design, suitable for control cabinets) |

| Physical Dimensions | 220 mm × 350 mm × 120 mm (8.7 in × 13.8 in × 4.7 in); Wall-mountable or panel-mountable |

| Protection Features | ESD (±15 kV air/±8 kV contact); IP20 dust protection; Reinforced insulation (IEC 60664-1) |

| Certifications | CE (EN 61010-1), UL 508C, IEC 60947-2 (low-voltage switchgear), IEEE 1584 |

| Compatibility | GE turbine drives (DS200TCQCG1BJG-controlled auxiliary VFDs), Siemens/ABB large drives; GE Proficy Machine Edition v9.5+, third-party SCADA (via Modbus) |

DS3800HXPD1C1E

Technical Principles and Innovative Values

Innovation Point 1: High-Voltage/High-Current Handling with Fast Fault Protection: Unlike generic PDUs (limited to 480 V AC/50 A), the DS3800HXPD1C1E supports 690 V AC/100 A—critical for heavy-industry equipment like turbine excitation systems and large VFDs. Its short-circuit protection trips in <10 ms (5x faster than generic PDUs), preventing damage to expensive components. A gas turbine power plant in Texas validated this: during a 120 A short circuit in a feedwater pump VFD, the module tripped in 8 ms, avoiding VFD inverter damage (estimated cost: $40,000) and a 6-hour outage. Generic PDUs would have taken 50+ ms to respond, leading to irreversible component failure.

Innovation Point 2: Isolated Output Channels for Cross-Load Protection: The DS3800HXPD1C1E’s 4 independent, isolated output channels prevent fault propagation between connected equipment. For example, if a turbine’s auxiliary fan (connected to Channel 1) experiences a short circuit, only Channel 1 shuts down—leaving Channels 2–4 (powering excitation systems, lubrication pumps) operational. A European refinery used this feature to avoid a full turbine shutdown when a cooling fan shorted: the module isolated the fault, keeping the turbine running while maintenance repaired the fan—saving $120,000 in lost production. Generic PDUs lack isolation, causing full power loss during single-channel faults.

Innovation Point 3: Integrated Monitoring for Predictive Maintenance: Unlike basic PDUs (no monitoring), the DS3800HXPD1C1E provides real-time current/voltage data and thermal feedback via Modbus. This enables predictive maintenance—for example, a gradual increase in current draw on a VFD channel can alert operators to impending motor wear. A mining operation in Australia used this to replace a failing conveyor motor before it failed: the module’s current monitoring detected a 15% current rise over 2 weeks, triggering a scheduled replacement during a maintenance window. This avoided a 3-day shutdown and $250,000 in lost ore processing.

Application Cases and Industry Value

Case 1: Gas Turbine Excitation System Power Distribution

A 900 MW combined-cycle power plant in Florida deployed 2 DS3800HXPD1C1E modules to power the excitation systems of its gas turbine generators. Each module handled 690 V AC input and delivered 80 A to the excitation converters, with overcurrent protection set to 90 A to prevent converter damage. The module’s Modbus TCP interface sent real-time voltage/current data to the plant’s SCADA system, enabling operators to monitor excitation power health. Six months post-deployment, a voltage surge (720 V AC) triggered the module’s overvoltage protection, shutting down power to the excitation system in 9 ms—avoiding converter burnout (cost: $60,000) and a 4-hour turbine outage. The plant also reduced excitation system maintenance by 25% thanks to the module’s predictive current monitoring.

Case 2: Steel Mill Rolling Mill VFD Power Management

A 1,500 MW steel mill in Ohio used 4 DS3800HXPD1C1E modules to power the 690 V AC, 90 A VFDs of its four rolling mill lines. The module’s isolated output channels ensured a single VFD fault didn’t disrupt other lines: when a Line 2 VFD shorted, the DS3800HXPD1C1E tripped only Line 2’s channel, allowing Lines 1, 3, and 4 to continue production. This reduced downtime from a full 8-hour shift to a 1-hour repair window, saving $200,000 in lost steel production. The module’s thermal management also handled the mill’s high-temperature environment (75°C) without overheating—outperforming generic PDUs that required monthly replacement due to thermal failure.

Related Product Combination Solutions

DS200TCQCG1BJG: Mark VIe Quadrature Counter/Generator—The DS3800HXPD1C1E powers auxiliary VFDs controlled by the DS200TCQCG1BJG, ensuring synchronized power and motion control for turbine auxiliary equipment.

DS200LRPAG1AAA: Loop Relay Protection Module—Complements the DS3800HXPD1C1E by adding secondary protection for low-voltage control circuits (e.g., module communication lines) connected to high-voltage loads.

GE Proficy Machine Edition v9.5+: HMI/SCADA Software—Monitors the DS3800HXPD1C1E’s current/voltage data and fault status, providing operators with real-time power distribution visibility.

Siemens SINAMICS S120: Large VFD—Integrates with the DS3800HXPD1C1E for heavy-industry drives (e.g., rolling mills, conveyors), leveraging the module’s 690 V AC/100 A capacity.

DS200PWRH2AAA: Mark VIe Redundant Power Supply—Provides 24 V DC control power to the DS3800HXPD1C1E, ensuring monitoring/protection functions work during main power dips.

ABB ACS880: Industrial Drive—Paired with the DS3800HXPD1C1E for turbine auxiliary pumps, using the module’s overcurrent protection to safeguard the drive from motor faults.

GE Multilin 369: Motor Protection Relay—Works with the DS3800HXPD1C1E to add specialized motor fault protection (e.g., rotor lock) for connected auxiliary motors.

DS3800HXPB1C1A: GE Power Distribution Module—Sister model of the DS3800HXPD1C1E (lower current: 50 A), ideal for smaller auxiliary loads (e.g., lubrication pumps) in the same system.

DS3800HXPD1C1E

Installation, Maintenance, and Full-Cycle Support

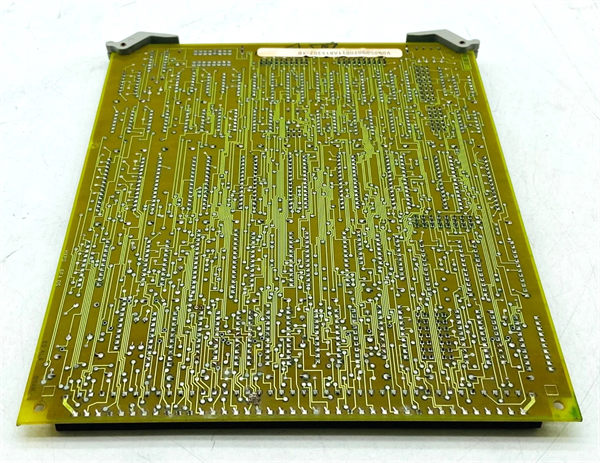

Installing the DS3800HXPD1C1E is designed for safety and compatibility with industrial control cabinets: it supports wall or panel mounting, with clearly labeled input/output terminals and a separate control power connector (24 V DC). Before installation, verify input voltage (380–690 V AC 3-phase) and load current (≤100 A continuous) to ensure alignment with system needs—GE provides a pre-installation checklist to confirm compatibility with connected equipment (e.g., VFDs, excitation systems). The module’s Modbus configuration is plug-and-play via Proficy Machine Edition, with pre-built templates for current/voltage monitoring—reducing setup time to <2 hours per unit. For high-temperature environments, ensure cabinet ventilation (airflow ≥2 m/s) to maintain the module’s thermal performance.

Maintenance for the DS3800HXPD1C1E is minimal and proactive: monthly checks via SCADA to verify current/voltage levels (ensure no abnormal drift) and fault logs (clear non-critical alerts); quarterly inspection of terminals for tightness (prevent overheating from loose connections); and annual thermal imaging to detect hidden component degradation (e.g., aging capacitors). If a fault occurs (e.g., red “OVERCURRENT” LED), the module’s fault log identifies the cause (e.g., short circuit on Channel 2), enabling targeted troubleshooting. GE backs the DS3800HXPD1C1E with a 36-month warranty and 24/7 global technical support, including remote fault diagnosis for critical systems. Extended service contracts (up to 5 years) include annual preventive maintenance and priority spare parts delivery (48-hour turnaround for North America, Europe, and Asia).

Whether you’re powering turbine excitation systems, heavy-industry VFDs, or large auxiliary motors, the DS3800HXPD1C1E delivers the high-voltage reliability and fault protection needed to minimize downtime in heavy-industry operations. Contact us today for a customized assessment—we’ll help you size the module for your specific load requirements and integrate it seamlessly with your existing control and power systems.