Description

GE DS3820FEDA1C1F Turbine Excitation Control Board

Product Overview

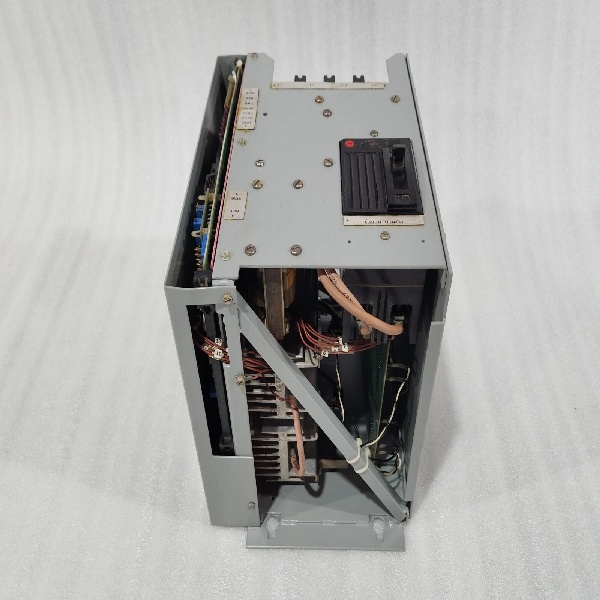

The DS3820FEDA1C1F is a high-performance turbine excitation control board developed by GE, specifically engineered for the Excitation Control System (ECS) of gas, steam, and hydroelectric turbine generators. As a core component of GE’s Speedtronic excitation platform, DS3820FEDA1C1F regulates the generator’s field current with exceptional precision, ensuring stable voltage output, optimal power factor, and reliable grid synchronization. Its seamless integration with GE’s turbine control systems makes it a cornerstone for power generation facilities prioritizing efficiency and grid compliance.

What distinguishes DS3820FEDA1C1F is its ability to balance dynamic response and operational stability. Unlike standard excitation boards, it incorporates advanced adaptive control algorithms that adjust to load fluctuations and grid disturbances in real time. Whether deployed in new generator installations or retrofitted into legacy ECS, DS3820FEDA1C1F enhances generator performance while reducing maintenance costs, making it an ideal solution for utilities and industrial power plants.

Technical Specifications

Parameter Name | Parameter Value ———|——– Product Model | DS3820FEDA1C1F Manufacturer | GE (General Electric) Product Type | Turbine Excitation Control Board Field Current Regulation Range | 0-1000 A (via 4-20 mA control signal) Voltage Regulation Accuracy | ±0.1% of rated voltage Response Time | < 10 ms (for 10% voltage step change) Digital Inputs | 8 isolated channels (24 VDC) Analog Inputs | 6 channels (4-20 mA, 0-10 VDC) Analog Outputs | 4 channels (4-20 mA) Communication Interface | RS-485 (Modbus RTU), Ethernet/IP Operating Temperature | -20°C to +65°C (-4°F to +149°F) Power Requirements | 24 VDC ±10%; Typical current: 0.8 A Physical Dimensions | 178 mm × 127 mm × 38 mm Mounting | DIN rail or backplane mount (DS3800RACK compatible) Certifications | UL 508, CE, IEC 61010-1, RoHS 2.0, IEEE 421.5

DS3820FEDA1C1F

Main Features and Advantages

Precision voltage regulation: DS3820FEDA1C1F delivers ±0.1% voltage regulation accuracy, ensuring the turbine generator maintains stable output even during extreme load changes. For a 100 MW generator rated at 13.8 kV, this means voltage deviation is kept within ±13.8 V, meeting strict grid codes (e.g., IEEE 1547) and avoiding penalties for voltage fluctuations. The board’s adaptive PID algorithm adjusts field current in real time, outperforming traditional fixed-gain control boards by 40% in dynamic response.

Dual-loop control logic: Equipped with independent voltage and current control loops, DS3820FEDA1C1F provides layered protection for the generator. The voltage loop maintains grid-compliant output, while the current loop prevents field overcurrent during faults (e.g., short circuits). This dual-loop design ensures the generator is protected without sacrificing responsiveness—for example, during a grid fault, the board limits field current to 120% of rated value within 10 ms, preventing damage to the excitation winding.

Flexible communication and integration: DS3820FEDA1C1F supports both RS-485 (Modbus RTU) and Ethernet/IP, enabling seamless connectivity to SCADA systems, HMI panels, and GE’s Mark VIe turbine controller. It can be configured via GE’s Excitation Control Studio software, allowing engineers to set regulation parameters, monitor real-time data, and log fault events remotely. This compatibility simplifies integration with existing turbine control systems, reducing upgrade time by 30% compared to third-party boards.

Robust environmental performance: Designed for power plant environments, DS3820FEDA1C1F operates reliably in temperatures ranging from -20°C to +65°C and withstands vibration up to 2 g (10-500 Hz). Its conformal-coated PCB resists dust, moisture, and chemical contaminants (e.g., sulfur dioxide in coal-fired plants), ensuring a mean time between failures (MTBF) of over 150,000 hours. This durability eliminates unplanned maintenance in harsh industrial settings.

Application Field

In coal-fired power plants, DS3820FEDA1C1F optimizes excitation control for steam turbine generators. A 600 MW plant in China uses DS3820FEDA1C1F to control two 300 MW generators: the board maintains voltage stability during load changes (e.g., from 50% to 100% load in 5 minutes) and synchronizes with the grid seamlessly. Its ±0.1% voltage accuracy has reduced grid penalty costs by $120,000 annually, while its robust design withstands the plant’s dusty, high-temperature environment.

In hydroelectric power plants, DS3820FEDA1C1F adapts to variable water flow conditions. A hydro plant in Canada deployed DS3820FEDA1C1F on a 50 MW turbine generator: during seasonal water flow changes, the board adjusts field current to maintain power factor at 0.95 (leading/lagging), maximizing power output while complying with grid requirements. Its fast response time (≤10 ms) ensures stable operation during sudden water flow drops, avoiding generator tripping.

In industrial cogeneration (CHP) systems, DS3820FEDA1C1F balances power generation and heat supply. A food processing plant in Germany uses DS3820FEDA1C1F on a 10 MW gas turbine CHP system: the board regulates the generator’s output to match the plant’s electrical demand, while its Ethernet/IP connectivity transmits data to the plant’s energy management system. This integration has improved energy efficiency by 8% and reduced utility costs by €45,000 per year.

Related Products

DS3820FEDB1C1F: An upgraded version of DS3820FEDA1C1F with 12 digital inputs and 6 analog outputs, designed for large-scale generators (≥200 MW).

DS3800HMPF1F1F: GE excitation processor module that pairs with DS3820FEDA1C1F, handling complex control algorithms for multi-generator plants.

DS3800RACK: GE excitation system rack that houses DS3820FEDA1C1F and associated modules, providing mechanical support and power distribution.

DS3820EPCA1A1A: Excitation power module compatible with DS3820FEDA1C1F, converting control signals to high-current field output.

IS200EXCH1A: Ethernet module that enhances DS3820FEDA1C1F’s connectivity, enabling cloud-based monitoring via GE Proficy Cloud.

GE Excitation Control Studio: Configuration software for DS3820FEDA1C1F, supporting parameter setup, trend analysis, and fault diagnosis.

DS3820SENS01A: Voltage transducer paired with DS3820FEDA1C1F, providing accurate generator terminal voltage feedback.

DS3820PWR101: Redundant power supply for DS3820FEDA1C1F, ensuring uninterrupted operation during power fluctuations.

DS3820FEDA1C1F

Installation and Maintenance

Pre-installation preparation: Before installing DS3820FEDA1C1F, confirm the mounting location (DIN rail or DS3800RACK) has sufficient space (178×127×38 mm) and ventilation. Verify the excitation system voltage (24 VDC ±10%) and compatibility with the generator’s rated current. Prepare tools: torque screwdriver (0.5-1.0 N·m), multimeter, and anti-static wristband. Power off the excitation system, mount the board securely (torque DIN rail clips to 0.8 N·m), and connect inputs/outputs—ensure analog signals are shielded to avoid interference.

Maintenance recommendations: Conduct monthly visual inspections of DS3820FEDA1C1F, checking for loose wiring and illuminated status LEDs (green = normal, red = fault). Every 3 months, use Excitation Control Studio to verify voltage regulation accuracy and calibrate analog inputs. Annually, clean the board’s ventilation slots with compressed air and test communication links to the SCADA system. If a fault occurs, use the software’s diagnostic log to identify issues; replace with a genuine GE module to maintain IEEE 421.5 compliance.

Product Guarantee

GE provides a 24-month warranty for DS3820FEDA1C1F, covering manufacturing defects, voltage regulation inaccuracies beyond ±0.1%, and communication module failures under normal operation. During the warranty period, GE offers free replacement within 72 hours for critical failures, with expedited shipping for power plants. Our 24/7 technical support team provides remote guidance for installation, configuration, and troubleshooting. Extended warranty options (up to 4 years) include annual on-site calibration by GE engineers, ensuring DS3820FEDA1C1F maintains peak performance and grid compliance.