Description

Detailed Parameter Table

| Parameter name | Parameter value |

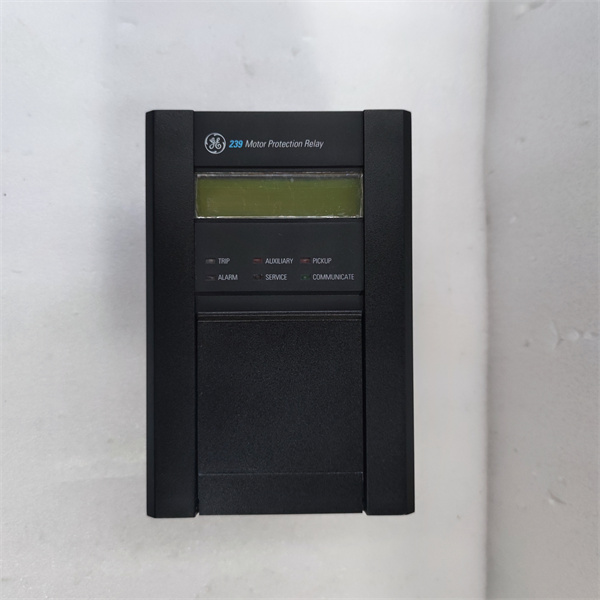

| Product model | 239-RTD-AN |

| Manufacturer | GE (General Electric) |

| Product category | RTD-Based Temperature Monitoring Timer Relay |

| Temperature sensing range | -200°C to +600°C, compatible with Pt100, Pt500, Pt1000 RTDs |

| Time range | 0.05 s to 100 h, with temperature-triggered timing functions |

| Control voltage | 12 VDC, 24 VDC, 110 VAC, 220 VAC (selectable by model variant) |

| Output type | 1 SPDT contact (5 A @ 250 VAC / 30 VDC) + 1 analog output (4-20 mA) |

| Temperature accuracy | ±0.1°C (at 0°C to +100°C), ±0.5°C over full range |

| Operating modes | Temperature-triggered delay on operate, temperature-based interval timing, over/under temperature alarm |

| RTD input | 3-wire or 4-wire RTD connection for enhanced accuracy |

| Operating temperature | -25°C to +70°C (ambient), ensuring performance in harsh environments |

| Storage temperature | -40°C to +85°C |

| Protection rating | IP20 (panel mount), IP65 (enclosed versions) |

| Mounting type | 35 mm DIN rail or panel mounting |

| Dimensions | 22.5 mm x 80 mm x 78 mm (width x height x depth) |

GE 239-RTD-AN

Product Introduction

GE’s 239-RTD-AN is an advanced RTD-based temperature monitoring timer relay, building on the core functionality of the standard 239 model by integrating precision temperature sensing with timing control. This hybrid device bridges temperature monitoring and time-dependent operations, making it ideal for industrial processes where thermal conditions dictate timing sequences—such as heat treatment, curing, or temperature-sensitive material handling.

The 239-RTD-AN combines a high-accuracy RTD input (supporting Pt100/500/1000 sensors) with the versatile timing capabilities of the 239 series. It can trigger timing functions when temperatures reach set thresholds (e.g., delaying a motor start until a furnace reaches 200°C) or regulate intervals based on thermal feedback (e.g., adjusting drying cycles if ambient temperature fluctuates). The addition of an analog output (4-20 mA) enables seamless integration with SCADA or PLC systems, providing real-time temperature data for centralized monitoring. Whether used in standalone mode or as part of a larger control network, this relay ensures precise coordination between temperature and timing, critical for quality and safety in thermal processes.

Core Advantages and Technical Highlights

Temperature-timed synchronization: The 239-RTD-AN uniquely links timing functions to temperature thresholds. For example, in plastic injection molding, it delays mold opening (delay on operate) until the melt temperature drops to 150°C, preventing part warping. This eliminates guesswork in thermal processes, where fixed timing often fails due to ambient variations.

High-precision RTD sensing: With ±0.1°C accuracy in the 0°C to 100°C range, the relay excels in applications like pharmaceutical lyophilization (freeze-drying), where precise temperature monitoring during timed cycles ensures product stability. The 3-wire/4-wire RTD connection minimizes lead resistance errors, critical for long sensor cables in large facilities.

Dual output versatility: The SPDT contact controls external devices (e.g., heaters, valves), while the 4-20 mA analog output transmits temperature data to HMIs or data loggers. In food processing, this allows operators to monitor oven temperatures in real time while the relay times cooking cycles, ensuring compliance with safety standards.

Adaptive timing logic: Unlike fixed timers, the 239-RTD-AN adjusts intervals based on temperature. In metal annealing, if a furnace heats slower than expected, it extends the hold time to ensure proper grain structure formation, reducing scrap rates.

Typical Application Scenarios

In heat treatment furnaces, the 239-RTD-AN manages annealing cycles. It triggers a 2-hour interval timer (temperature-based) only after the furnace reaches 800°C, ensuring the metal is held at temperature long enough to soften. If the temperature drops below 780°C during the interval, it pauses the timer until the setpoint is restored, maintaining process integrity.

In cold storage facilities, the relay monitors freezer temperatures and uses over-temperature alarm mode to trigger a 10-minute delay on operate for backup cooling systems. This prevents false alarms from brief temperature spikes while ensuring timely intervention during genuine failures, protecting perishable goods.

In solar panel manufacturing, the 239-RTD-AN controls lamination presses. It delays press activation (delay on operate) until the adhesive reaches 120°C, then times a 5-minute compression cycle (interval mode). The analog output sends temperature data to a SCADA system, enabling traceability of each panel’s lamination conditions.

GE 239-RTD-AN

Related Model Recommendations

239-TC-AN: A thermocouple-based variant of the 239-RTD-AN, compatible with J, K, T-type thermocouples for high-temperature applications (up to 1200°C), ideal for foundry operations.

239-RTD-2D: A dual-output version with two SPDT contacts, allowing independent control of two devices (e.g., a heater and a fan) based on the same temperature-timed logic.

GE CR306: A heavy-duty contactor that pairs with the 239-RTD-AN to handle high-current loads like industrial heaters, while the relay provides precise temperature-timed control.

239-RTD-IP65: A weatherproof enclosure variant, designed for outdoor temperature-timed applications such as agricultural greenhouse climate control, where dust and moisture resistance are essential.

GE IS200TDBSH2ACC: A discrete I/O module that integrates with the 239-RTD-AN in large systems, converting the analog output to digital signals for PLC processing.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Mount the 239-RTD-AN on a 35 mm DIN rail or panel, ensuring separation from high-voltage components to reduce EMI. Use shielded 3-wire/4-wire cables for RTD connections, with the shield grounded at the relay end. Verify the control voltage matches the model (e.g., 24 VDC) and connect the analog output (4-20 mA) to the SCADA/PLC system using twisted-pair wiring. Calibrate the RTD input using a precision temperature bath before commissioning.

Maintenance suggestions: Inspect RTD connections quarterly for corrosion (especially in humid environments) and clean with a dry cloth. Test the analog output accuracy annually using a multimeter, adjusting via trim pots if drift exceeds ±0.5 mA. Check contact resistance of the SPDT output—replace the relay if resistance exceeds 100 mΩ. For IP65 versions, inspect gaskets yearly to maintain waterproofing.

Troubleshooting tips: If temperature readings are erratic, check for loose RTD connections or damaged cables. If timing functions fail to trigger, verify the temperature setpoints and mode configuration. The relay includes a front-panel LED that flashes error codes for common issues (e.g., RTD open circuit), simplifying diagnostics.

Service and Guarantee Commitment

GE provides a 3-year warranty for the 239-RTD-AN, covering defects in materials and workmanship. Their technical support team offers 24/7 assistance for RTD calibration, mode configuration, and system integration via online portals and email. For critical applications, GE engineers can perform on-site commissioning to optimize temperature thresholds and timing parameters.

Extended warranty options (up to 5 years) include annual calibration checks to maintain accuracy. Customers receive access to software tools for remote monitoring of the relay’s status and historical temperature-timing data. This comprehensive support ensures the 239-RTD-AN delivers reliable performance in temperature-critical industrial processes, maximizing uptime and product quality.