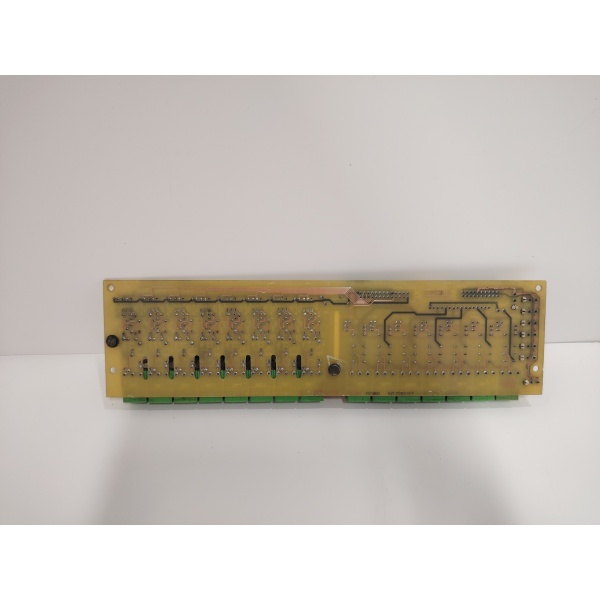

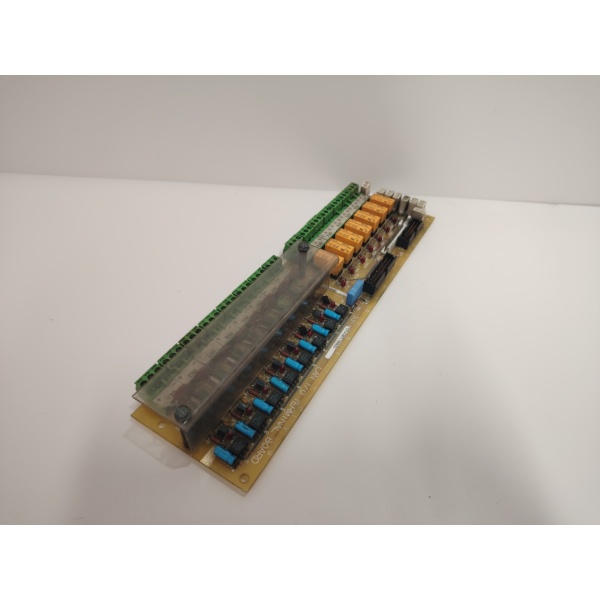

Description

531X307LTBAKG1: Product Overview

The GE 531X307LTBAKG1 is a low-density termination board assembly (TBA) designed for GE’s Mark V series of turbine control systems. As a critical component of the Mark V ecosystem, it enables seamless signal termination and conditioning for field devices (e.g., temperature transmitters, pressure sensors, contactors) and communicates processed signals to the Mark V controller.

Role in Automation Systems:

Positioned as an “I/O signal interface” in the Mark V architecture, the 531X307LTBAKG1 performs two primary functions:

-

Signal Termination: Provides dedicated terminals for analog (e.g., 4–20 mA, 0–10 V DC) and digital (e.g., contact closures) signals from field devices, ensuring secure and stable connections.

-

Signal Conditioning: Filters, amplifies, and scales raw signals to remove noise and improve integrity, critical for maintaining turbine stability in power generation applications.

Core Functionality:

-

Multi-Signal Support: Handles 24 analog inputs (e.g., thermocouples, RTDs) and 24 digital I/O points (e.g., pushbuttons, interlocks), accommodating diverse field device requirements.

-

Hazardous-Area Certification: ATEX Cat 3 and IECEx certifications allow direct installation in Zone 2/22 explosive atmospheres (e.g., petrochemical plants, offshore platforms) without additional containment.

-

Military-Grade Connectivity: MIL-DTL-38999 connectors withstand vibration, shock, and harsh environments, ensuring reliable signal transmission in turbine halls.

-

Surge Protection: 4kV surge suppression (triple-stage TVS + gas discharge + varistors) protects against lightning and transient voltage spikes, reducing downtime in coastal or high-voltage environments.

Platform Benefits (Mark V Series):

The 531X307LTBAKG1 leverages GE’s Mark V platform, which is renowned for:

-

Reliability: Industrial-grade components and a rugged design ensure 24/7 operation in harsh turbine environments (e.g., high temperature, vibration).

-

Scalability: Supports expansion with additional TBAs to accommodate growing system demands (e.g., adding more sensors or actuators).

-

Integration: Seamlessly integrates with Mark V controllers (e.g., LDCC) and operator interfaces, reducing setup time and effort.

GE 531X307LTBAKG1

Technical Specifications

-

Model Number: 531X307LTBAKG1

-

Manufacturer: GE (General Electric)

-

Product Type: Low-Density Termination Board Assembly (TBA)

-

Series: Mark V

-

Signal Capacity: 48 points (24 analog + 24 digital)

-

Input Voltage Range:

-

24–230 V AC (60Hz, G1)

-

24–250 V DC (G1/G2)

-

115–230 V AC (50Hz, G1)

-

-

Input Current: 4–10 mA peak (AC), 4–8 mA (DC)

-

Connectors: MIL-DTL-38999 Series III (x2, for field device connections)

-

Protection Features:

-

4kV surge protection (triple-stage)

-

EMI/RFI shielding (aluminum enclosure)

-

1500V AC channel-to-channel isolation

-

-

Operating Temperature: -40°C to +85°C (-40°F to 185°F)

-

Storage Temperature: -40°C to +85°C (-40°F to 185°F)

-

Humidity: 5–95% non-condensing

-

Dimensions: 185 mm × 105 mm × 32 mm (7.28 in × 4.13 in × 1.26 in)

-

Weight: 0.5 kg (1.1 lbs)

-

Certifications: ATEX Cat 3, IECEx, SIL 2, UL 508

Core Features & Customer Value

1. Hazardous-Area Compatibility:

The 531X307LTBAKG1’s ATEX Cat 3 and IECEx certifications eliminate the need for external explosion-proof enclosures, reducing installation costs by up to 40% in petrochemical or offshore applications. This is critical for facilities where flammable vapors or dusts pose operational risks.

2. High Signal Integrity:

With 1500V AC channel-to-channel isolation and EMI/RFI shielding, the board ensures accurate signal transmission from field devices to the Mark V controller. This is essential for maintaining turbine stability—even minor signal noise can lead to incorrect control decisions (e.g., misadjusting fuel flow).

3. Military-Grade Durability:

MIL-DTL-38999 connectors are designed to withstand 500+ mating cycles and extreme vibration (7g @ 10–500Hz), making them ideal for turbine hall environments. This durability reduces maintenance costs and ensures reliable operation over the board’s lifecycle.

4. Flexible Signal Support:

The board’s 48-point capacity (24 analog + 24 digital) accommodates a wide range of field devices, from temperature transmitters to contactors. This flexibility allows engineers to expand system capabilities without replacing existing hardware—critical for power plants with legacy Mark V installations.

GE 531X307LTBAKG1

Typical Applications

The GE 531X307LTBAKG1 is widely used in turbine control systems for:

-

Power Generation:

-

Provides signal termination for gas/steam turbines, enabling the Mark V controller to monitor temperature, pressure, and position sensors. For example, in a combined-cycle power plant, the board processes signals from turbine blade position sensors to adjust fuel flow for optimal efficiency.

-

-

Petrochemical Industry:

-

Installed in Zone 2/22 explosive atmospheres (e.g., ethylene plants, refineries), the board interfaces with pressure transmitters and flame detectors, ensuring safe and reliable operation in hazardous environments.

-

-

Offshore Platforms:

-

Withstands saltwater corrosion and vibration, the board provides signal termination for offshore turbine drives, supporting oil and gas extraction operations.

-