Description

Detailed Parameter Table

| Parameter name | Parameter value |

| Product model | D20 EME 2400 – 21004 |

| Manufacturer | GE |

| Product category | Industrial control module |

| Power supply voltage | 20 – 60 VDC, 100 – 300 VDC / 85 – 264 VAC |

| Operating frequency | 50 kHz |

| Communication interface | RS – 232, RS – 485, Ethernet (supports 10Base – T, 10Base – 2, 10Base – FL), D.20 Link HDLC |

| Input channels | 16 |

| Output channels | 16 |

| Load rating | 1 A per channel |

| Protection level | IP54 |

| Operating temperature | – 20 °C to 60 °C |

| Storage temperature | N/A |

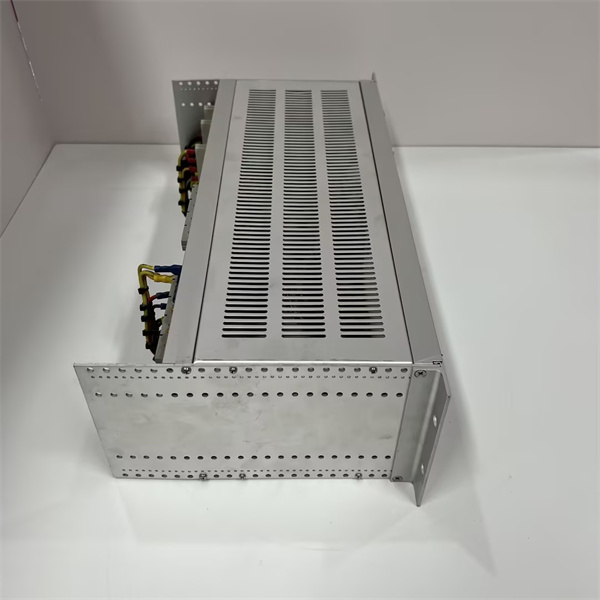

| Dimensions | 19″ wide x 5.25″ high x 8.1″ deep (approx. 482.6 mm x 133.35 mm x 205.74 mm) |

| Weight | 0.5 kg |

GE D20 EME 2400-21004

Product Introduction

The GE D20 EME 2400 – 21004 is a high – performance industrial control module, an integral part of GE’s advanced control system offerings. It serves as a powerful hub for managing and regulating various industrial processes. This module is designed to handle complex control tasks with ease, providing seamless integration between different components within an automation setup.

In industrial automation systems, the D20 EME 2400 – 21004 plays a pivotal role. It can interface with a wide range of field devices, such as sensors and actuators, collecting data from sensors and sending control signals to actuators. Its Ethernet and serial communication interfaces enable efficient data transfer, allowing it to communicate with other modules, programmable logic controllers (PLCs), and supervisory control and data acquisition (SCADA) systems. This connectivity is crucial for achieving centralized control and monitoring in industrial plants.

Core Advantages and Technical Highlights

Robust Connectivity

The D20 EME 2400 – 21004 offers an extensive range of communication interfaces. With multiple RS – 232 and RS – 485 ports, along with Ethernet support for 10Base – T, 10Base – 2, and 10Base – FL, it can adapt to different network topologies. In large industrial complexes with diverse communication requirements, this module can effortlessly integrate with existing systems, ensuring smooth data flow between various devices. The D.20 Link HDLC ports further enhance its communication capabilities, enabling reliable data transfer over long distances.

High – Capacity I/O

Featuring 16 input and 16 output channels, each with a load rating of 1 A, this module can handle a significant number of field devices. In manufacturing plants where numerous sensors and actuators are used for process control, the D20 EME 2400 – 21004 can easily interface with them. The high load rating per channel ensures that it can drive even power – hungry actuators without issues, making it suitable for applications that require substantial control power.

Exceptional Durability

Built with a protection level of IP54, the module is highly resistant to dust and water splashing. This makes it suitable for use in harsh industrial environments, such as factories, power plants, and mines. The operating temperature range of – 20 °C to 60 °C allows it to function reliably in both cold storage facilities and hot manufacturing workshops. Its robust construction can also withstand vibrations and mechanical shocks, ensuring long – term performance in challenging industrial settings.

Typical Application Scenarios

Power Generation

In power plants, the GE D20 EME 2400 – 21004 is used to monitor and control various parameters. It can connect to sensors that measure temperature, pressure, and flow rate in steam turbines or gas turbines. By collecting this data through its input channels and processing it, the module can then send control signals to actuators, such as valves and pumps, to optimize the power generation process. In a nuclear power plant, its reliability and safety features are of utmost importance, as it helps in ensuring the safe and efficient operation of the plant.

Manufacturing

On manufacturing floors, this module is widely deployed in automated production lines. It interfaces with proximity sensors, photoelectric sensors, and limit switches to monitor the position and movement of components. Based on the sensor data, it can control the operation of robotic arms, conveyor belts, and other actuators. In an automotive manufacturing plant, for example, the D20 EME 2400 – 21004 can ensure that parts are accurately positioned for assembly, improving production efficiency and product quality.

Substation Automation

In substations, the module is used for monitoring and controlling electrical equipment. It can connect to voltage and current sensors, circuit breakers, and power transformers. By analyzing the electrical data from these devices, it can detect faults and take corrective actions. For instance, if a voltage imbalance is detected, the module can send a signal to adjust the tap changers of transformers, ensuring stable power distribution.

GE D20 EME 2400-21004

Related Model Recommendations

D20AC: An analog input peripheral module related to the D20 system. It works in tandem with the D20 EME 2400 – 21004 by providing analog input capabilities. In applications where analog sensor data needs to be processed, the D20AC can be used along with the D20 EME 2400 – 21004 to form a comprehensive control solution.

D200 power supplies and chargers: These power – related components are essential for powering the D20 EME 2400 – 21004 and other modules in the D20 system. They ensure a stable power supply, which is crucial for the reliable operation of the D20 EME 2400 – 21004 in various industrial applications.

GE Fanuc series modules: Some modules in the GE Fanuc series are compatible with the D20 EME 2400 – 21004. For example, certain communication modules can enhance the overall communication capabilities of the system when used in combination with the D20 EME 2400 – 21004, allowing for more complex and efficient data transfer within the industrial control network.

D20EME (other variants): There may be other versions of the D20EME module with different memory configurations or additional features. These can be used as upgrades or alternatives depending on the specific requirements of the industrial application. For instance, a variant with more memory can be used when the application demands higher data storage and processing capabilities.

GE D20 system expansion modules: These modules can be used to expand the functionality of the D20 system, which includes the D20 EME 2400 – 21004. They may add more input/output channels, improve communication speed, or enhance the overall performance of the system in specific application scenarios.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing the GE D20 EME 2400 – 21004, ensure that the installation environment is clean and free from excessive dust and moisture. The ambient temperature should be within the specified operating range of – 20 °C to 60 °C. Tools required include a screwdriver for mounting the module in the appropriate chassis. Disconnect all power sources from the system to avoid electrical hazards during installation. Thoroughly review the wiring diagram provided in the product manual before connecting any field devices to the module’s terminals. Make sure that the power supply voltage to be connected is within the specified range of 20 – 60 VDC, 100 – 300 VDC / 85 – 264 VAC.

Maintenance Suggestions

For daily maintenance, regularly inspect the module for any signs of physical damage, such as cracks or loose components. Check the communication ports and terminals for corrosion or loose connections. If there are issues with data transfer or control signals, use diagnostic tools to determine whether the problem lies with the D20 EME 2400 – 21004 or the connected devices. In case of a malfunction, refer to the troubleshooting guide in the product manual. When replacing any parts, only use genuine GE components to ensure compatibility and optimal performance. Periodically clean the module to prevent dust accumulation, which could affect its heat dissipation and overall functionality.

Service and Guarantee Commitment

GE stands firmly behind the quality of the D20 EME 2400 – 21004. The product comes with a standard warranty against manufacturing defects. In the unlikely event of a product failure during the warranty period, GE will replace or repair the module free of charge. GE’s global technical support team is available around the clock to assist customers with installation, commissioning, and troubleshooting. Customers can access a wealth of online resources, including user manuals, technical bulletins, and software updates. For critical applications, GE offers extended warranty options and on – site service agreements. This demonstrates GE’s confidence in the product’s quality and its unwavering commitment to providing excellent customer service, ensuring that customers can rely on the D20 EME 2400 – 21004 for long – term, trouble – free operation in their industrial automation systems.