Description

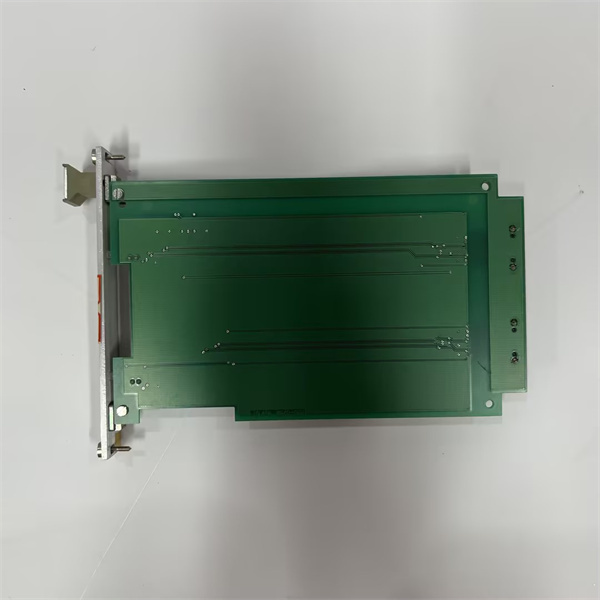

GE D20 EME210BASE-T

Product Identification and Nomenclature

The “GE D20 EME210BASE-T” is a specific component within GE’s D20 system product line. The “D20” indicates it belongs to the D20 series, which is widely used in industrial control and automation. “EME” likely stands for Ethernet/Memory Expansion, highlighting its role in enhancing the system’s Ethernet communication and memory capabilities. The “10BASE-T” specifically refers to the Ethernet standard it supports, which is a 10 Mbps baseband Ethernet specification using twisted-pair cables, a common standard in early Ethernet networks that remains relevant in certain industrial setups. This naming convention clearly identifies the product’s series, core functions, and key technical specifications, making it easy for users to recognize its purpose and compatibility within the D20 system.

Detailed Parameter Table

| Parameter name | Parameter value |

| Product model | D20 EME210BASE-T |

| Manufacturer | GE Fanuc |

| Product category | Ethernet/Memory Expansion Module for D20 system |

| Ethernet standard | 10BASE-T, using twisted-pair cables (Category 3, 4, or 5) for data transmission |

| Data transfer rate | 10 Mbps (half-duplex or full-duplex mode) |

| Network topology | Supports star topology, typical in 10BASE-T networks |

| Memory options | May include battery-backed SRAM, with options such as 8 MB or 16 MB for data storage |

| Communication ports | 10BASE-T Ethernet port, along with possible serial ports (RS-232/485) for additional connectivity |

| Power supply | 20 – 60 VDC, compatible with the D20 system’s power infrastructure |

| Operating temperature | -20 °C to 60 °C, suitable for harsh industrial environments |

| Dimensions | Compact design to fit into D20 system enclosures, approximately 19″ x 5.25″ x 8.1″ (similar to other D20 EME modules) |

GE D20 EME210BASE-T

Product Introduction

The GE D20 EME210BASE-T is a specialized Ethernet/Memory Expansion Module designed to integrate seamlessly with the D20 system. Its primary function is to provide reliable 10BASE-T Ethernet connectivity, enabling the D20 system to communicate with other networked devices, while also offering memory expansion for data storage.

In industrial environments, where stable and secure communication is crucial for monitoring and controlling processes, the 10BASE-T standard supported by this module ensures compatibility with legacy network infrastructure. It serves as a bridge between the D20 system and other industrial devices, such as HMIs, PLCs, and SCADA systems, allowing for the exchange of critical data. Additionally, the memory expansion feature enables the storage of process data, configuration settings, and logs, which are essential for troubleshooting, analysis, and maintaining system integrity. Whether deployed in manufacturing plants, power distribution facilities, or other industrial settings, the D20 EME210BASE-T plays a vital role in enhancing the D20 system’s connectivity and data management capabilities.

Core Advantages and Technical Highlights

Reliable 10BASE-T Ethernet communication: The support for the 10BASE-T standard ensures stable data transmission at 10 Mbps, which is sufficient for many industrial control applications where real-time data exchange is not extremely high-speed but requires reliability. In a factory with legacy network infrastructure built around 10BASE-T, this module allows the D20 system to integrate seamlessly without the need for expensive network upgrades. For example, in a textile manufacturing plant with older machinery, the module can facilitate communication between the D20 system and the machinery’s control units, ensuring smooth production monitoring.

Enhanced memory capabilities: The inclusion of battery-backed SRAM provides non-volatile storage, ensuring that critical data such as process parameters, event logs, and configuration settings are retained even during power outages. This is particularly important in applications where data loss could lead to operational disruptions or safety issues. In a water treatment plant, for instance, the module can store data on water flow rates, chemical dosages, and system alarms, allowing operators to review historical data for process optimization and compliance reporting.

Industrial-grade durability: Designed to operate within a temperature range of -20 °C to 60 °C, the D20 EME210BASE-T can withstand the harsh conditions often found in industrial environments, including extreme temperatures, vibration, and electromagnetic interference. This durability ensures consistent performance in settings such as steel mills, where high temperatures and electrical noise are prevalent, or in outdoor power substations exposed to varying weather conditions.

Seamless integration with D20 system: As a dedicated module for the D20 system, it integrates effortlessly with other components, requiring minimal configuration. This plug-and-play compatibility reduces installation time and ensures that the module works in harmony with the system’s existing hardware and software. In a power generation facility using the D20 system for turbine control, the module can quickly connect to the system’s central controller, enabling data transmission to the plant’s SCADA system without complex setup.

Typical Application Scenarios

Industrial automation networks: In manufacturing facilities with legacy 10BASE-T networks, the D20 EME210BASE-T enables the D20 system to connect to the plant’s network, facilitating communication between different production lines. For example, in an automotive parts factory, it can transmit data from the D20 system controlling the machining process to a central HMI, allowing operators to monitor production metrics such as cycle times and defect rates in real-time.

Power distribution monitoring: In power substations, the module can connect the D20 system to a network of intelligent electronic devices (IEDs) using 10BASE-T Ethernet. It can collect data on voltage, current, and breaker status from these IEDs, store it in its memory, and transmit it to a remote SCADA system for monitoring and analysis. This helps in ensuring the reliable operation of the power grid and enables quick response to faults.

Legacy system upgrades: Many industrial facilities still use older equipment and networks based on 10BASE-T. The D20 EME210BASE-T allows these facilities to upgrade their D20 systems’ communication capabilities without replacing the entire network infrastructure. For instance, a food processing plant with a 10BASE-T network can use the module to enable the D20 system to communicate with new data logging devices, enhancing process tracking without incurring the cost of a full network upgrade.

GE D20 EME210BASE-T

Related Model Recommendations

GE D20 EME modules with higher Ethernet standards: For facilities looking to transition to faster networks, GE offers D20 EME modules supporting 100BASE-TX or even Gigabit Ethernet. These modules, such as the D20 EME with 100BASE-TX, can be used alongside the D20 EME210BASE-T during a phased network upgrade, ensuring compatibility with both legacy and new network segments.

GE D20 I/O expansion modules: To complement the D20 EME210BASE-T’s communication capabilities, D20 I/O expansion modules can be added to increase the number of sensors and actuators the system can control. For example, analog I/O modules can be used to monitor temperature and pressure in a chemical plant, with the D20 EME210BASE-T transmitting this data to a central control system.

GE Ethernet switches for industrial networks: Industrial-grade Ethernet switches compatible with 10BASE-T can be used to expand the network and connect multiple D20 systems equipped with the D20 EME210BASE-T module. These switches, designed to withstand industrial environments, ensure reliable data transmission between devices, even in noisy electrical conditions.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing the D20 EME210BASE-T, power off the D20 system. Inspect the system’s chassis for dust or damage and clean it if necessary. Ensure that the 10BASE-T network cables (Category 3, 4, or 5) are properly terminated and tested for continuity. Verify that the power supply to the chassis is within the 20 – 60 VDC range. Use anti-static wristbands when handling the module to prevent electrostatic damage. Review the installation manual to identify the correct slot in the chassis for the module.

Commissioning steps: Insert the module into the designated slot in the D20 chassis and secure it with mounting screws. Connect the 10BASE-T Ethernet cable to the module’s Ethernet port and the network switch. Power on the system and check the module’s status LEDs – a steady light on the Ethernet port indicates a valid network connection. Use the D20 system’s configuration software to enable the Ethernet interface and set network parameters such as IP address and subnet mask. Test communication by pinging other devices on the network from the D20 system. Verify that data is being stored in the module’s memory by checking log files or configuration settings.

Maintenance suggestions: Regularly inspect the module’s Ethernet cable connections to ensure they are secure and free from damage. Clean the module and its surroundings periodically using compressed air to remove dust, which can cause overheating. Monitor the module’s status through the D20 system’s software, checking for network errors or memory issues. If network communication fails, check the cable, switch, and network configuration before troubleshooting the module itself. Replace the battery in the battery-backed SRAM as recommended by GE to ensure data retention during power outages. Keep the module’s firmware updated using GE’s official software to ensure compatibility and performance.

Service and Guarantee Commitment

GE provides a standard warranty for the D20 EME210BASE-T, covering manufacturing defects under normal operating conditions. Their technical support team is available to assist with installation, configuration, and troubleshooting, offering remote guidance and on-site service if required.

Customers can access a range of resources, including user manuals, technical datasheets, and firmware updates, through GE’s online portal. Training courses are also available to help maintenance personnel understand the module’s operation and integration with the D20 system. Extended warranty options may be available, providing additional coverage for a specified period. GE’s commitment to service ensures that users can rely on the D20 EME210BASE-T for consistent performance in their industrial applications.