Description

Detailed Parameter Table

| Parameter name | Parameter value |

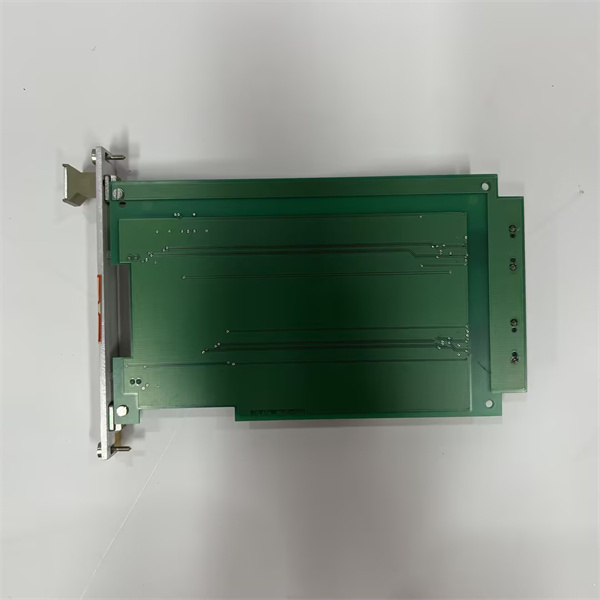

| Product model | D20 EME210BASE-T |

| Manufacturer | GE |

| Product category | Industrial Ethernet Communication Module |

| Power supply | 24 VDC ± 10% |

| Ethernet standard | 10BASE-T/100BASE-TX, supporting full-duplex and half-duplex modes |

| Data transfer rate | 10 Mbps / 100 Mbps (auto-negotiation) |

| Communication distance | Up to 100 meters over Cat5e or higher twisted-pair cables |

| Operating temperature | -40 °C to 70 °C |

| Storage temperature | -55 °C to 85 °C |

| Protection level | IP30 (suitable for panel mounting with additional enclosure protection) |

| Dimensions | 120 mm x 80 mm x 30 mm (W x H x D) |

| Weight | Approximately 150 grams |

| Protocols supported | Modbus TCP/IP, Ethernet/IP, D20 Link over Ethernet |

| Mounting type | DIN rail mount (35 mm standard) |

GE D20 EME210BASE-T

Product Introduction

The GE D20 EME210BASE-T is a high-reliability industrial Ethernet communication module, specifically designed for seamless integration into GE’s D20 series control systems. As a critical connectivity component, it serves as the bridge between field devices, controllers, and upper-level monitoring systems in industrial automation networks.

This module is engineered to meet the rigorous demands of industrial environments, ensuring stable data transmission even in harsh conditions. By supporting the 10BASE-T/100BASE-TX Ethernet standards, the D20 EME210BASE-T enables high-speed, real-time communication, which is essential for modern industrial control systems. Whether in power generation, manufacturing, or process industries, it plays a vital role in enabling centralized monitoring, remote control, and data exchange, thereby enhancing the efficiency and responsiveness of the entire automation ecosystem.

Core Advantages and Technical Highlights

Robust Industrial-Grade Performance

The D20 EME210BASE-T is built to withstand the challenges of industrial settings. Its wide operating temperature range (-40 °C to 70 °C) allows it to function reliably in extreme cold, such as in outdoor substations in frigid regions, and high heat, like in factory environments near machinery. The module’s rugged design also resists vibration and electromagnetic interference (EMI), ensuring uninterrupted communication even in areas with heavy electrical equipment or motor noise. This robustness minimizes downtime and ensures consistent performance in critical applications.

Versatile Ethernet Connectivity

Supporting both 10 Mbps and 100 Mbps data rates with auto-negotiation, the D20 EME210BASE-T adapts to varying network requirements. It seamlessly integrates with existing Ethernet infrastructures, whether upgrading from older 10BASE-T systems or connecting to high-speed 100BASE-TX networks. The module’s compatibility with multiple protocols—Modbus TCP/IP, Ethernet/IP, and D20 Link over Ethernet—enhances its flexibility, allowing it to communicate with a wide range of industrial devices, including PLCs, HMIs, and SCADA systems from different manufacturers.

Easy Integration and Deployment

Designed for DIN rail mounting, the D20 EME210BASE-T simplifies installation in standard control cabinets. Its compact dimensions (120 mm x 80 mm x 30 mm) save space, making it suitable for crowded panel layouts. The auto-negotiation feature eliminates the need for manual speed and duplex settings, reducing configuration time and potential errors. Additionally, the module’s compatibility with Cat5e or higher cables ensures easy sourcing of connectivity materials, further streamlining deployment in industrial projects.

Secure and Reliable Data Transmission

In industrial networks, data integrity is paramount. The D20 EME210BASE-T incorporates features to ensure secure and reliable data transmission. It supports full-duplex communication, which eliminates data collisions and improves throughput. The module also includes built-in error-checking mechanisms to detect and correct transmission errors, reducing the risk of data loss or corruption. This reliability is crucial in applications such as real-time control of production lines or monitoring of critical infrastructure, where incorrect data could lead to operational failures.

Typical Application Scenarios

Power Generation Facilities

In power plants, the GE D20 EME210BASE-T connects turbine control systems, generator protection relays, and SCADA servers. It enables real-time transmission of operational data—such as turbine speed, temperature, and power output—from field devices to the central control room. For example, in a combined-cycle power plant, the module facilitates communication between the gas turbine controller, steam turbine controller, and the main SCADA system, allowing operators to monitor and adjust the entire plant’s performance from a single interface. Its ability to withstand high temperatures and EMI ensures reliable operation near turbine enclosures and high-voltage equipment.

Manufacturing Automation

In automated manufacturing plants, the D20 EME210BASE-T integrates robotic workcells, conveyor systems, and quality control sensors into a unified network. It transmits commands from the central PLC to robots and receives feedback on their position and task status. In an automotive assembly line, for instance, the module connects robotic welders, part-feeding systems, and vision inspection cameras. This enables synchronized operation: the PLC sends welding parameters to the robots via the module, while the vision system transmits inspection results back, allowing for immediate adjustments if a defect is detected. The module’s high data rate ensures that time-critical commands are delivered without delay, maintaining production efficiency.

Water and Wastewater Treatment

In water treatment facilities, the D20 EME210BASE-T links pumps, valves, and sensors (e.g., pH, turbidity, and flow meters) to the control system. It enables remote monitoring and control of treatment processes, such as chemical dosing and filtration. For example, in a municipal wastewater plant, the module transmits data from flow meters in the primary clarifiers to the PLC, which then adjusts the sludge pump speed to maintain optimal flow rates. The module’s ruggedness ensures reliable operation in damp environments, while its protocol support allows integration with both legacy and modern treatment equipment, simplifying system upgrades.

GE D20 EME210BASE-T

Related Model Recommendations

D20 EME100FX: A fiber-optic Ethernet module compatible with the D20 EME210BASE-T. It extends communication distances beyond 100 meters, making it ideal for connecting remote areas of a plant (e.g., outdoor pump stations to the main control room).

D20 ECC100: A communication gateway that works with the D20 EME210BASE-T to convert between different protocols (e.g., Modbus RTU to Modbus TCP/IP). Useful for integrating legacy serial devices into Ethernet networks.

GE D20 Power Supply Module: Provides stable 24 VDC power to the D20 EME210BASE-T and other D20 series modules. Ensures consistent operation even during voltage fluctuations, which is critical for maintaining network connectivity.

D20 HMI Panel: A human-machine interface that connects to the D20 EME210BASE-T to display real-time data and allow operator input. Enables local monitoring and control of connected devices in the field.

D20 EME210RED: A redundant Ethernet module that pairs with the D20 EME210BASE-T to provide failover capability. In critical applications, such as nuclear power plant control systems, it ensures network continuity if the primary module fails.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing the GE D20 EME210BASE-T, ensure the mounting location is a clean, dry control cabinet with a 35 mm DIN rail. Verify that the power supply is 24 VDC ± 10% and that the cabinet temperature remains within -40 °C to 70 °C. Tools needed include a screwdriver for securing the module to the rail, a cable stripper for preparing Ethernet cables, and a cable tester to verify connections. Disconnect power to the cabinet before installation to prevent electrical hazards. Use Cat5e or higher twisted-pair cables with RJ45 connectors, ensuring cables are routed away from high-voltage lines to minimize EMI. Follow the module’s pinout diagram to connect power and Ethernet cables correctly.

Maintenance Suggestions

For routine maintenance of the D20 EME210BASE-T, inspect the module quarterly for loose connections or signs of damage (e.g., bent pins on the Ethernet port). Clean dust from the module’s vents using compressed air to prevent overheating. Test network connectivity periodically using diagnostic tools to verify data transfer rates and check for errors. If communication issues arise, check the Ethernet cable for damage, verify the power supply voltage, and ensure the module’s firmware is up to date (updates are available via GE’s online portal). Replace damaged cables or connectors promptly to maintain signal integrity. When replacing the module, use genuine GE parts to ensure compatibility with the D20 system.

Service and Guarantee Commitment

GE backs the D20 EME210BASE-T with a 12-month warranty, covering manufacturing defects and component failures under normal operating conditions. During the warranty period, GE will repair or replace defective modules free of charge. The global technical support team is available 24/7 to assist with installation, troubleshooting, and firmware updates via phone, email, or remote diagnostic tools. Customers can access a library of resources—including user manuals, installation guides, and application notes—on GE’s official website. For critical applications, GE offers extended warranty options and on-site support contracts, ensuring minimal downtime and long-term reliability. This commitment reflects GE’s confidence in the D20 EME210BASE-T‘s quality and its dedication to customer success.