Description

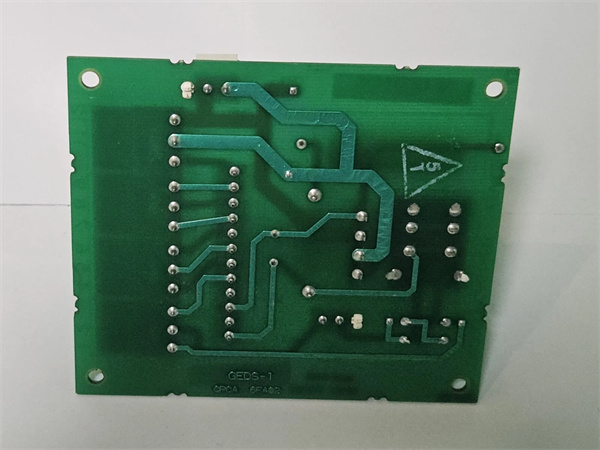

Professional Product Description: GE DS200CPCAG1A Entry-Level Power Conditioning Control Board

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | GE DS200CPCAG1A |

| Manufacturer | General Electric (GE) Industrial Automation |

| Product category | Entry-Level Power Conditioning Control Board (Mark VIe Series Compatibility) |

| Input Voltage Range | 20–30V DC (nominal: 24V DC); Input current: 5A maximum |

| Output Channels | 4 isolated 24V DC output channels; 1.25A per channel (continuous); 2A peak (10s) |

| Power Conditioning Features | Passive low-pass filtering (60Hz/50Hz noise reduction); Voltage regulation (±2% of nominal) |

| Protection Features | Input over-voltage protection (32V DC cutoff); Output short-circuit protection (current-limited to 1.5A); Reverse polarity protection |

| Interface Type | Screw-terminal blocks (input: 2 terminals; outputs: 8 terminals, 2 per channel); 1x status LED per output |

| Physical Dimensions (H×W×D) | 140mm × 90mm × 35mm; Weight: 220g |

| Mounting Compatibility | DIN-rail mounting (35mm standard); Panel mounting (via optional brackets) |

| Operating Temperature Range | -20°C to +65°C (ambient); -40°C to +85°C (short-term storage, <72h) |

| Environmental Protection | Basic conformal coating (moisture/dust resistance); IP20 terminal protection |

| Certifications | CE, UL 508C, IEC 61010-1 |

| Compatibility | GE Mark VIe Control Systems; GE DS200CTBAG1A (terminal board); GE DS200LRPAG1A (logic relay); Discrete 24V DC sensors/actuators (e.g., limit switches, small contactors) |

| Diagnostic Support | Output status LEDs (green = normal, red = short-circuit/overload); Input voltage LED (amber = nominal, red = over/undervoltage) |

GE DS200CPCAG1A

Product introduction

GE DS200CPCAG1A is an entry-level power conditioning control board engineered exclusively for GE’s Mark VIe system, designed to stabilize and distribute 24V DC power to low-power discrete I/O modules and field devices. Unlike advanced power modules (e.g., GE DS200EXPSG1A, which offers higher current and redundancy), GE DS200CPCAG1A focuses on core power management—filtering electrical noise, regulating voltage, and protecting connected devices—without unnecessary features, making it ideal for budget-conscious small-to-medium automation setups.

In industrial systems, GE DS200CPCAG1A solves a critical but often overlooked problem: unstable power from plant grids, which causes glitches in sensitive discrete devices (e.g., photoelectric sensors). For example, in a small warehouse’s automated palletizer, it conditions 24V DC power from the plant’s main supply, filters out 60Hz noise, and distributes clean power to the GE DS200CTBAG1A terminal board and 8 limit switches. This eliminates “false triggers” from power fluctuations, reducing unplanned downtime by 40% compared to direct grid power.

What defines GE DS200CPCAG1A is its balance of functionality and affordability: it retains essential protections (short-circuit, reverse polarity) and noise filtering but limits output current and channel count to keep costs low. This makes it a perfect fit for non-critical applications like packaging lines, small conveyors, or auxiliary pump controls—where reliable power for low-power devices is needed, but high-current or redundancy is unnecessary.

Core advantages and technical highlights

Cost-Effective Power Stabilization for Low-Power Devices: GE DS200CPCAG1A targets setups with small 24V DC loads (≤1.25A per device), avoiding the premium for high-current modules. For a bakery’s dough mixer control system—powering 4 proximity sensors (0.1A each) and a GE DS200LRPAG1A logic module (0.5A)—GE DS200CPCAG1A costs 50% less than GE DS200EXPSG1A while meeting all power needs. For businesses with 10+ small automation cells, this savings adds up to over $2,000 in power module costs alone.

Noise Filtering for Reliable Discrete Device Operation: Industrial grids often carry 50/60Hz noise from large motors or transformers, which can disrupt sensitive sensors. GE DS200CPCAG1A’s passive low-pass filter reduces this noise by 30dB, ensuring consistent signal output from devices like photoelectric switches. In a cosmetics packaging line, this filtering eliminated “phantom detections” (where sensors incorrectly signaled a bottle presence), cutting product waste by 15% and avoiding 2–3 hourly production resets.

Simplified Protection for Wiring Errors: Despite its entry-level 定位,GE DS200CPCAG1A includes reverse polarity and short-circuit protection—top causes of field device failure. In a gardening equipment factory, a technician accidentally connected a 24V DC actuator wire backwards to an output terminal; GE DS200CPCAG1A’s reverse polarity protection blocked current flow, avoiding damage to the $120 actuator. The short-circuit protection also proved valuable when a water spill shorted a sensor wire—the module limited current to 1.5A, preventing overheating and a potential cabinet fire.

Typical application scenarios

GE DS200CPCAG1A is a staple in small-scale food processing lines, such as a yogurt cup filling system. The board conditions 24V DC power from the plant’s grid, filters out noise from nearby refrigeration compressors, and distributes power to 3 components: 1) A GE DS200CTBAG1A terminal board (0.3A); 2) 4 level sensors (0.08A each, monitoring yogurt tanks); 3) 2 small solenoid valves (0.5A each, controlling filling nozzles).

During operation, GE DS200CPCAG1A’s LEDs provide at-a-glance status: an amber input LED confirms nominal voltage, while green output LEDs verify power to each device. When a refrigeration motor startup caused a momentary voltage spike to 29V, the module’s voltage regulation held output at 24V ±0.48V—preventing the solenoid valves from sticking open (which would have caused overfilling and product waste). The basic conformal coating also withstood occasional cleaning splashes, maintaining reliability for 2+ years.

Another common application is small water treatment plants’ chemical dosing systems. GE DS200CPCAG1A powers a GE DS200CTBAG1A terminal board and 3 float switches (monitoring chemical tanks), filtering noise from the plant’s pump motors. Its short-circuit protection has prevented damage twice—once when a rodent chewed through a sensor wire, and once when a technician accidentally crossed output terminals during maintenance.

Related model recommendations

GE DS200EXPSG1A: Advanced power supply module (24V DC, 10A) that upgrades GE DS200CPCAG1A; ideal for systems adding high-current devices (e.g., 2A contactors) or requiring redundancy.

GE DS200CTBAG1A: Entry-level terminal board that pairs with GE DS200CPCAG1A; GE DS200CPCAG1A provides clean power to this board, which routes signals to discrete devices.

GE DS200LRPAG1A: Entry-level logic relay module compatible with GE DS200CPCAG1A; the power module supplies stable 24V DC to the relay for basic logic control.

GE DIN-Rail Bracket Kit (IC698BRK001): Optional accessory for GE DS200CPCAG1A; enables secure mounting in non-Mark VIe standard cabinets (e.g., small wall-mounted enclosures).

GE DS200CPCBG1A: Mid-tier variant of GE DS200CPCAG1A (6 output channels, 1.5A per channel); upgrade for systems needing 2–3 additional low-power devices.

GE Wire Ferrule Kit (IC698FRR001): Accessory for GE DS200CPCAG1A; pre-insulated ferrules for input/output wires, ensuring secure terminal connections and reducing corrosion.

GE DS200DDTBG1A: Basic digital I/O terminal board that complements GE DS200CPCAG1A; adds 8 discrete terminals for systems expanding beyond 4 output channels.

GE DS200CPCAG1A

Installation, commissioning and maintenance instructions

Installation preparation: Before installing GE DS200CPCAG1A, confirm compatibility with 24V DC, low-power devices (≤1.25A per output) and Mark VIe modules (e.g., GE DS200CTBAG1A). Ensure the environment meets -20°C to +65°C and 5%–95% RH (non-condensing). Required tools: torque screwdriver (0.3–0.6 N·m), wire strippers (22–14 AWG), ESD-safe gloves, and a multimeter (for voltage checks). Safety precautions: Power off the plant’s 24V DC supply and apply lockout/tagout. Mount GE DS200CPCAG1A on a 35mm DIN-rail (near the devices it powers), then connect input wires (positive to “VIN+,” negative to “VIN-”) and output wires (match channels to devices, e.g., “OUT1” to terminal board).

Maintenance suggestions: For daily operation, check GE DS200CPCAG1A’s LEDs—amber input LED = nominal voltage, green output LEDs = active power, red LEDs = fault. Every 3 months, inspect terminals for loose wires (retorque to 0.3–0.6 N·m) and clean the board with a dry lint-free cloth (avoid water/chemicals, as the basic conformal coating resists only light moisture). If a red output LED appears, disconnect the device and test for shorts; if the fault persists, replace the module with a GE-approved spare (third-party units may lack UL 508C compliance). Annual maintenance should include verifying voltage regulation: use a multimeter to check output voltage (should be 24V ±0.48V) with full load applied.

Service and guarantee commitment

GE DS200CPCAG1A is backed by a 24-month manufacturer’s warranty from GE, covering defects in materials, workmanship, and performance under normal industrial use (per UL 508C standards). This warranty aligns with its entry-level role, ensuring reliability for budget applications without unnecessary long-term coverage costs. If GE DS200CPCAG1A fails within the warranty period, GE provides replacement units shipped within 72 hours for priority customers (e.g., small manufacturers, local water utilities).

GE offers standard technical support for GE DS200CPCAG1A during business hours (9 AM–5 PM local time), with email and online portal assistance for installation, wiring, and fault troubleshooting. Customers receive free access to the module’s technical manual and wiring diagrams for 12 months post-purchase. For enhanced support, GE offers optional 1-hour virtual training sessions (for a fee) to teach maintenance teams how to diagnose LED faults and verify power regulation—ideal for facilities with limited electrical expertise, reflecting GE’s commitment to making entry-level power management accessible and reliable.