Description

DS200CPCAG1ABB: Product Overview

The GE DS200CPCAG1ABB is a contactor pilot board designed specifically for GE Mark V gas turbine control systems, a flagship platform for industrial power generation and turbine automation. As part of the Mark V ecosystem, it plays a pivotal role in regulating the excitation system—critical for maintaining turbine stability and power output.

Role in Automation Systems:

Positioned as a “contactor control hub” in Mark V architectures, the DS200CPCAG1ABB performs two primary functions:

-

Voltage Conversion: Transforms incoming 115 V AC (from the turbine’s power supply) into 105 V DC, which is required to energize the contactor coils. This conversion ensures that contactors operate reliably under varying load conditions.

-

Contactor Activation: Sends control signals to contactors, dictating when to open or close based on commands from the turbine’s main controller. For example, when the turbine starts, the DS200CPCAG1ABB activates contactors to connect the generator to the grid.

Core Functionality:

-

Precision Voltage Regulation: The board’s circuitry maintains a stable 105 V DC output, even with fluctuations in the input AC voltage. This stability is critical for preventing contactor chatter (rapid opening/closing), which can damage turbine components.

-

Flexible Connectivity: The 12-pin and 2-pin connectors allow seamless integration with the Mark V system’s backplane, while the four terminal blocks support up to 12 signal wires—enabling connection to multiple contactors and sensors.

-

24 V DC Power Relay: A built-in relay provides auxiliary power to the contactor coils, ensuring that the board can handle high-current loads without overheating.

-

Robust Design: Constructed with industrial-grade components, the DS200CPCAG1ABB withstands harsh environments (e.g., high temperature, vibration) commonly found in turbine halls.

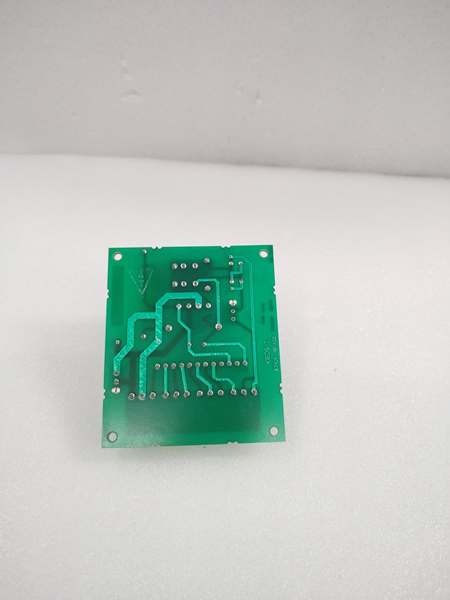

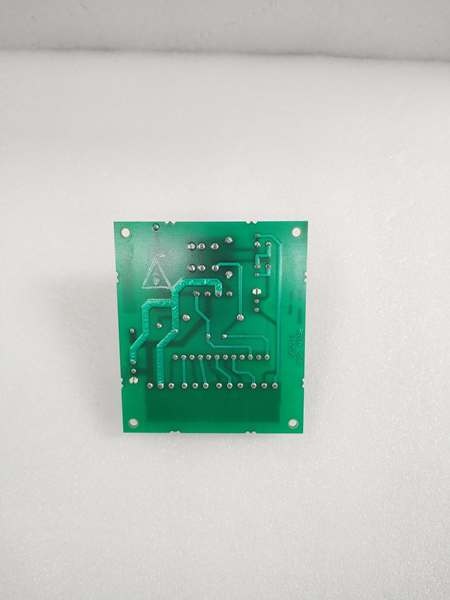

GE DS200CPCAG1ABB

Platform Benefits (Mark V Series):

The DS200CPCAG1ABB leverages GE’s Mark V platform, which is renowned for:

-

Reliability: The Mark V system is the industry standard for gas turbine control, with a proven track record of 24/7 operation in power plants worldwide.

-

Scalability: The platform supports expansion with additional I/O modules, allowing facilities to adapt to growing power demands.

-

Integration: The DS200CPCAG1ABB seamlessly integrates with other Mark V components (e.g., exciter modules, sensor interfaces), reducing setup time and effort.

Technical Specifications

-

Model Number: DS200CPCAG1ABB (Variant of DS200CPCAG1 series)

-

Manufacturer: GE (General Electric)

-

Product Type: Contactor Pilot Board

-

Series: Mark V (Gas Turbine Control)

-

Input Voltage: 115 V AC (±10%)

-

Output Voltage: 105 V DC (±5%)

-

Connector Types: 1× 12-pin (main system connection), 2× 2-pin (auxiliary devices)

-

Terminal Blocks: 4 (each supports up to 3 signal wires)

-

Power Relay: 24 V DC, 10 A (max)

-

Operating Temperature: -35°C to +65°C (-31°F to 149°F)

-

Storage Temperature: -40°C to +85°C (-40°F to 185°F)

-

Humidity: 5–95% non-condensing

-

Board Dimensions: 23.8 cm × 8.6 cm × 2.5 cm (9.4 in × 3.4 in × 1.0 in)

-

Weight: 0.45 kg (1 lb)

-

Certifications: CE, UL (inferred from GE industrial product standards)

GE DS200CPCAG1ABB

Core Features & Customer Value

1. Reliable Contactor Control:

The DS200CPCAG1ABB’s precision voltage regulation and robust design ensure that contactors operate reliably, even in harsh industrial environments. For example, in a power plant, the board prevents contactor chatter during turbine startup, avoiding costly downtime.

2. Flexible Integration:

The board’s multiple connectors and terminal blocks allow it to interface with a wide range of contactors and sensors, reducing the need for additional hardware changes. This flexibility saves time and money during installation.

3. Rugged Industrial Design:

The DS200CPCAG1ABB’s operating temperature range (-35°C to +65°C) and compact form factor make it suitable for turbine halls, where temperature fluctuations and vibration are common. Its durable construction minimizes maintenance requirements, reducing total cost of ownership.

4. Easy Maintenance:

The board’s terminal blocks and connectors are designed for easy access, allowing maintenance personnel to quickly diagnose and repair issues. For example, if a contactor fails to activate, technicians can use a multimeter to check the DS200CPCAG1ABB’s output voltage—simplifying troubleshooting.

Typical Applications

The GE DS200CPCAG1ABB is widely used in industrial automation systems for:

-

Power Generation:

-

Controls contactors in gas/steam turbines, enabling reliable connection/disconnection of the generator to the grid.

-

-

Manufacturing:

-

Used in industrial machinery (e.g., pumps, compressors) to control contactors that regulate power flow.

-

-

Petrochemical Industry:

-

Controls contactors in refinery equipment (e.g., distillation columns, pumps), ensuring safe and efficient operation.

-