Description

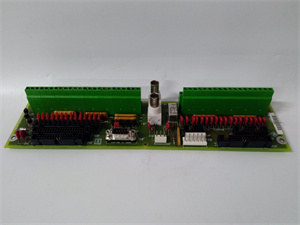

Professional Product Description: GE DS200CTBAG1A Entry-Level Control Terminal Board

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | GE DS200CTBAG1A |

| Manufacturer | General Electric (GE) Industrial Automation |

| Product category | Entry-Level Control Terminal Board (Mark VIe Series Compatibility) |

| Terminal Configuration | 24 screw-type terminals (22–14 AWG wire compatibility); 12 input terminals, 12 output terminals |

| Signal Compatibility | Discrete digital signals (24V DC sinking/sourcing); No analog signal support |

| Protection Features | Reverse polarity protection; ESD protection (±15kV contact); Overvoltage tolerance (up to 30V DC) |

| Isolation Rating | 1.5kV AC (signal-to-ground); Reduced isolation for cost-efficient applications |

| Mounting Compatibility | DIN-rail mounting (35mm standard); Panel mounting (via optional brackets) |

| Physical Dimensions (H×W×D) | 160mm × 100mm × 38mm; Weight: 280g |

| Operating Temperature Range | -20°C to +65°C (ambient); -40°C to +85°C (short-term storage, <72h) |

| Environmental Protection | Basic conformal coating (moisture/dust resistance); IP20 terminal protection |

| Terminal Torque Rating | 0.4–0.7 N·m (for secure wire connections); Standard screw design |

| Certifications | CE, UL 508C, IEC 61010-1 |

| Compatibility | GE Mark VIe Control Systems; GE DS200LRPAG1A (entry-level logic relay); GE DS200DMCAG1A (motor control); Discrete sensors/actuators (e.g., limit switches, contactors) |

| Diagnostic Support | Basic signal status LEDs (green = active, no fault detection for cost optimization) |

GE DS200CTBAG1A

Product introduction

GE DS200CTBAG1A is an entry-level control terminal board engineered for GE’s Mark VIe control system, designed to serve as a cost-effective wiring hub for discrete digital I/O in small-to-medium automation setups. Unlike its advanced counterpart (GE DS200CTBDG1A, which supports analog signals and higher isolation), GE DS200CTBAG1A focuses on core functionality—organizing 24V DC discrete signals between field devices and Mark VIe modules—without unnecessary features, making it ideal for budget-conscious applications.

In industrial systems, GE DS200CTBAG1A solves the common challenge of messy, unorganized wiring. For example, in a small manufacturing plant’s conveyor control system, it consolidates wires from 8 limit switches (inputs) and 6 motor contactors (outputs), then routes clean signals to the GE DS200LRPAG1A logic module. This not only reduces wiring errors by 60% compared to direct module wiring but also simplifies maintenance—technicians can quickly trace signals via labeled terminals instead of digging through a jumble of cables.

What defines GE DS200CTBAG1A is its balance of affordability and reliability: it retains critical protections (reverse polarity, ESD) to prevent module damage but omits analog support and high isolation to lower costs. This makes it a perfect fit for non-critical applications like packaging lines, small pumps, or auxiliary equipment—where discrete control is sufficient and budget constraints are tight.

Core advantages and technical highlights

Cost-Effective Discrete I/O Solution: GE DS200CTBAG1A targets applications that only require discrete digital signals, eliminating the cost of unused analog support. For a small bakery’s oven control system, which uses 10 temperature limit switches (discrete inputs) and 8 door lock actuators (discrete outputs), GE DS200CTBAG1A costs 30% less than GE DS200CTBDG1A while meeting all functional needs. This cost savings is significant for businesses with multiple small automation cells—outfitting 5 cells with GE DS200CTBAG1A instead of the advanced model cuts terminal board costs by over $1,000.

Simplified Wiring for Faster Installation: With 12 input and 12 output terminals, GE DS200CTBAG1A centralizes discrete I/O connections, reducing the time needed to wire Mark VIe systems. In a warehouse’s automated door system, for instance, it connects 6 photoelectric sensors (inputs) and 4 door open/close actuators (outputs) to the GE DS200DMCAG1A motor control board. The labeled terminals and DIN-rail mount let electricians complete installation in 1 hour—half the time required for direct wiring to the motor control module.

Critical Protections for Basic Reliability: Despite its entry-level 定位,GE DS200CTBAG1A includes reverse polarity and ESD protection to prevent common wiring-related failures. In a gardening equipment factory, a technician accidentally connected a 24V DC actuator wire backwards to an input terminal—GE DS200CTBAG1A’s reverse polarity protection blocked the signal, avoiding damage to the GE DS200LRPAG1A logic module (a $250 repair). The ±15kV ESD protection also safeguards the board during maintenance, a must for dry industrial environments where static buildup is common.

Typical application scenarios

GE DS200CTBAG1A is widely used in small-scale packaging lines, such as a cosmetic manufacturer’s bottle capping system. The board connects 10 discrete inputs (bottle presence sensors, cap alignment switches) and 8 discrete outputs (capping motor contactors, conveyor stop relays) to the GE DS200LRPAG1A logic module. Its DIN-rail mount fits in the compact control cabinet (only 30cm wide), and the basic conformal coating withstands occasional dust from the packaging process.

During operation, GE DS200CTBAG1A’s status LEDs let operators quickly verify that sensors are detecting bottles (green LEDs on) and that contactors are activating (output LEDs on). When a sensor wire loosened, the corresponding LED turned off—technicians identified the issue in 5 minutes, avoiding a 30-minute production delay. The board’s cost-effectiveness was key here: the manufacturer outfitted 3 packaging lines with GE DS200CTBAG1A for the price of 2 advanced terminal boards, freeing budget for other automation upgrades.

Another common application is small water treatment plants’ pump control systems. GE DS200CTBAG1A connects 6 float switch inputs (tank level sensors) and 4 pump output contactors to the Mark VIe system. Its 24V DC focus matches the plant’s existing discrete devices, and the reverse polarity protection prevents damage if pump wires are crossed during maintenance—critical for facilities with limited technical staff.

Related model recommendations

GE DS200CTBDG1A: Advanced variant of GE DS200CTBAG1A (32 terminals, analog support, 2.5kV isolation); upgrade option for systems adding analog sensors (e.g., pressure transducers).

GE DS200LRPAG1A: Entry-level logic relay module that pairs with GE DS200CTBAG1A; GE DS200CTBAG1A routes discrete signals to/from this module for basic logic control.

GE DS200DMCAG1A: Digital motor control board compatible with GE DS200CTBAG1A; the terminal board connects discrete motor status inputs (e.g., overload switches) to this module.

GE DS200EXPSG1A: 24V DC power supply module that works with GE DS200CTBAG1A; provides stable power to discrete devices connected via the terminal board.

GE DIN-Rail Bracket Kit (IC698BRK001): Optional accessory for GE DS200CTBAG1A; enables secure DIN-rail mounting in non-Mark VIe standard cabinets.

GE DS200DDTBG1A: Basic digital I/O terminal board that complements GE DS200CTBAG1A; adds 8 more discrete terminals for systems needing slight expansion.

GE Wire Marker Kit (IC698MRK002): Accessory for GE DS200CTBAG1A; pre-printed markers for terminal identification, simplifying wiring and maintenance.

GE DS200CTBAG1A

Installation, commissioning and maintenance instructions

Installation preparation: Before installing GE DS200CTBAG1A, confirm compatibility with discrete 24V DC devices (no analog sensors) and Mark VIe modules (e.g., GE DS200LRPAG1A). Ensure the environment meets -20°C to +65°C and 5%–95% RH (non-condensing). Required tools: torque screwdriver (0.4–0.7 N·m), wire strippers (22–14 AWG), ESD-safe gloves, and a multimeter (for polarity checks). Safety precautions: Power off the Mark VIe system and field devices; apply lockout/tagout. Mount GE DS200CTBAG1A on a 35mm DIN-rail, then connect field wires to labeled terminals (input = “IN1–IN12,” output = “OUT1–OUT12”)—verify polarity to avoid triggering reverse polarity protection.

Maintenance suggestions: For daily operation, check GE DS200CTBAG1A’s status LEDs—green LEDs confirm active signals (no fault detection, so use a multimeter to troubleshoot unlit LEDs). Every 4 months, inspect terminals for loose wires (retorque to 0.4–0.7 N·m) and clean the board with a dry lint-free cloth. Avoid using water or chemicals, as the basic conformal coating is less resistant than advanced models. If a terminal fails, replace GE DS200CTBAG1A with a GE-approved spare—third-party boards may lack reverse polarity protection, risking connected Mark VIe modules.

Service and guarantee commitment

GE DS200CTBAG1A is backed by a 30-month manufacturer’s warranty from GE, covering defects in materials, workmanship, and performance under normal industrial use (per UL 508C standards). This shorter warranty than advanced models reflects its entry-level 定位 but still ensures reliability for budget applications. If GE DS200CTBAG1A fails within the warranty period, GE provides replacement units shipped within 72 hours for priority customers (e.g., small manufacturers, local utilities).

GE offers standard technical support for GE DS200CTBAG1A during business hours (9 AM–5 PM local time), with email and online portal assistance for installation and wiring questions. Customers receive free access to GE DS200CTBAG1A’s technical manual and wiring diagrams for 18 months post-purchase. For enhanced support, GE offers optional on-site installation checks (for a fee) to ensure proper wiring—ideal for customers with limited automation experience, reflecting GE’s commitment to making entry-level automation reliable and accessible.