Description

DS200CTBAG1A: Product Overview

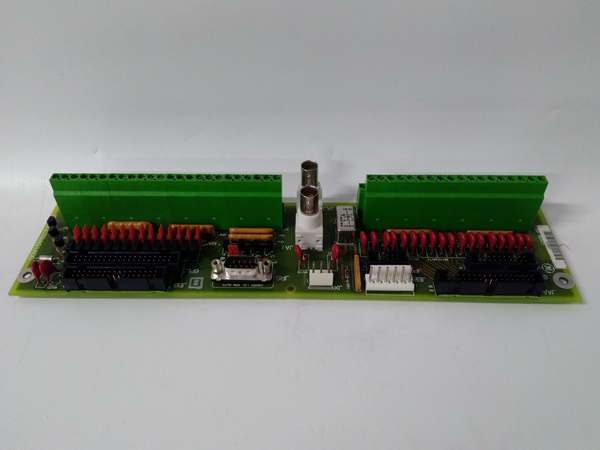

The GE DS200CTBAG1A is an analog I/O terminal board designed specifically for GE Speedtronic™ Mark V distributed control systems (DCS), the industry standard for gas, steam, and hydro turbine control in power generation. As part of the Mark V ecosystem, it combines the functions of a signal conditioner (for analog inputs) and a terminal hub (for signal distribution), acting as a “bridge” between field devices (e.g., turbine blade position sensors, fuel flow meters) and the turbine control unit. Its primary role is to ensure accurate signal transmission and system reliability—critical for maintaining turbine stability and efficiency.

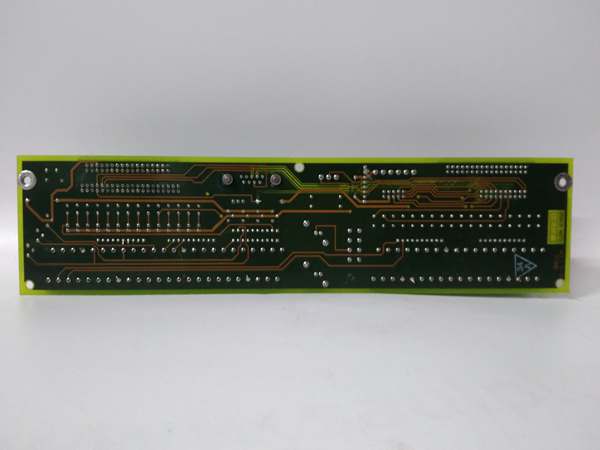

Engineered for the demanding conditions of turbine halls, the DS200CTBAG1A features a robust PCB layout and high-precision signal processing circuitry to withstand vibration, dust, and electromagnetic interference (EMI). Its legacy compatibility makes it ideal for retrofitting aging Mark V systems—common in power plants operating turbines for 20+ years—where replacing the entire control architecture is cost-prohibitive. Whether used in 7EA gas turbines or 9F steam turbines, the DS200CTBAG1A ensures reliable signal processing, directly extending the operational life of critical turbine control systems.

Role in Automation Systems

Positioned as a “field-to-controller signal gateway” in Mark V architectures, the DS200CTBAG1A performs two key functions:

-

Analog Signal Conditioning: Receives raw analog signals from field devices (e.g., a thermocouple measuring turbine exhaust temperature) and scales/conditions them into a format suitable for the turbine control unit (e.g., converting millivolt signals to 4–20 mA current loops).

-

Signal Distribution: Acts as a centralized terminal hub, routing conditioned analog signals to the turbine control unit and transmitting control commands from the controller to actuators (e.g., servo valves for fuel regulation).

Its core value lies in bridging the gap between field devices and the control unit—a critical step in maintaining turbine stability, as even minor signal inaccuracies can lead to process instability (e.g., turbine speed variations) or equipment damage (e.g., excitation system failure).

Core Functionality

-

High-Precision Signal Processing: The DS200CTBAG1A offers 12-bit resolution for analog inputs, ensuring precise signal representation (error < ±0.1% full-scale). This is critical for applications like turbine exhaust temperature monitoring, where small deviations can impact fuel efficiency and emissions.

-

Flexible Signal Handling: Supports multiple analog signal types (LVDT, thermocouple, 4–20 mA, ±10 V DC) through configurable input channels, making it adaptable to diverse field devices. This flexibility reduces the need for additional signal conditioning hardware, saving time and money during installation.

-

Galvanic Isolation: Uses optocouplers to isolate field devices from the controller, protecting sensitive electronics from voltage spikes and electromagnetic interference (EMI) in harsh industrial environments.

-

Legacy Compatibility: Fully compatible with existing Mark V components (e.g., STCA, TCQC boards), reducing the cost of system upgrades. This makes it an ideal choice for power plants with aging Mark V systems, where replacing the entire control architecture is not feasible.

DS200CTBAG1A

Technical Specifications

|

Parameter

|

Specification

|

|---|---|

|

Model Number

|

DS200CTBAG1A

|

|

Manufacturer

|

General Electric (GE)

|

|

Product Type

|

Analog I/O Terminal Board

|

|

Series

|

Mark V (Gas/Steam Turbine Control)

|

|

Form Factor

|

6U Eurocard (160 mm × 233 mm)

|

|

Bus Standard

|

Proprietary Mark V bus (compatible with Mark V Series controllers)

|

|

Input Channels

|

Configurable (e.g., 8 analog inputs, 4–20 mA or ±10 V DC)

|

|

Output Channels

|

Configurable (e.g., 4 analog outputs, 4–20 mA or ±10 V DC)

|

|

Isolation

|

Galvanic isolation (optocouplers, 1500 V AC channel-to-channel)

|

|

Resolution

|

12-bit (analog input), 10-bit (analog output)

|

|

Accuracy

|

±0.1% (full-scale, analog input), ±0.2% (full-scale, analog output)

|

|

Operating Temperature

|

0°C to +55°C (32°F to 131°F)

|

|

Storage Temperature

|

-40°C to +85°C (-40°F to 185°F)

|

|

Humidity

|

5–95% non-condensing

|

|

Weight

|

~0.2 kg (0.44 lbs)

|

|

Certifications

|

CE, UL (inferred from GE industrial product standards)

|

Core Features & Customer Value

1. Reliable Signal Processing:

The DS200CTBAG1A’s high-precision signal conditioning ensures that the turbine control unit receives accurate data from field devices. For example, in a power plant, the board can precisely measure turbine exhaust temperature (via a thermocouple) and convert it to a 4–20 mA signal for the controller, which adjusts fuel flow to maintain optimal efficiency.

2. Flexible Configuration:

Configurable input/output channels allow engineers to customize the board’s functionality for different field devices, reducing the need for additional signal conditioning hardware. This flexibility saves time and money during installation, especially in retrofit projects.

3. Rugged Industrial Design:

The board’s operating temperature range (0°C to +55°C) and compact form factor make it suitable for harsh industrial environments. Its DIN rail mounting option simplifies installation in crowded control cabinets.

4. Easy Integration:

Mark V bus compatibility ensures seamless integration with existing Mark V systems, minimizing downtime and effort during upgrades. This is invaluable for facilities with legacy Mark V installations, allowing them to enhance system capabilities without replacing entire architectures.

DS200CTBAG1A

Typical Applications

The GE DS200CTBAG1A is widely used in industrial automation systems for:

-

Power Generation:

-

Conditions analog signals from gas/steam turbines (e.g., blade position, fuel flow, temperature) for real-time control, ensuring stable power output.

-

-

Manufacturing:

-

Used in assembly lines to process analog signals from sensors (e.g., pressure, flow) and control actuators (e.g., valves, motors).

-

-

Petrochemical Industry:

-

Controls analog signals from refinery equipment (e.g., distillation columns, pumps), ensuring safe and efficient operation in hazardous environments.

-