Description

Detailed Parameter Table

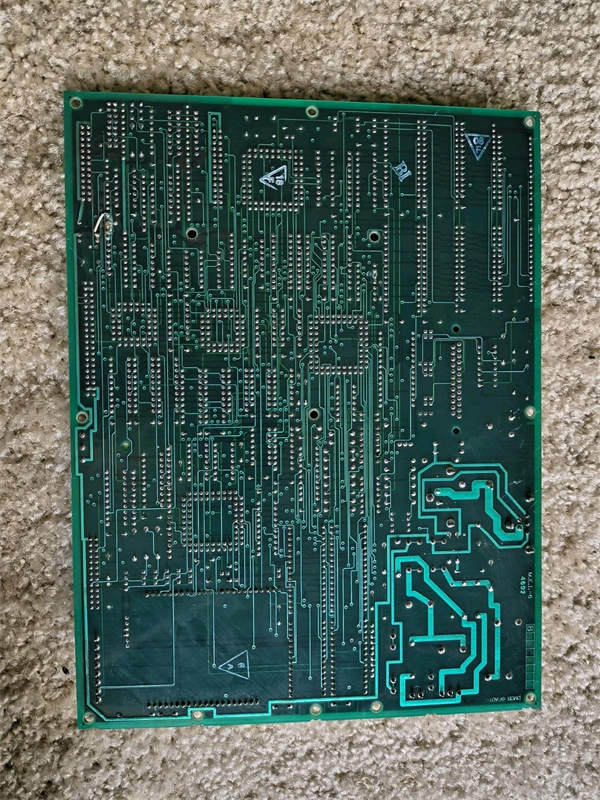

| Parameter Name | Parameter Value |

| Product model | GE DS200DMCBG1A |

| Manufacturer | General Electric (GE) Industrial Automation |

| Product category | Digital Motor Control Board (for Medium-Voltage Motor Drives) |

| Motor Compatibility | 3-phase AC induction motors; 0.75kW – 75kW (1HP – 100HP) |

| Control Modes | V/F (Volts per Hertz), Sensorless Vector Control, Closed-Loop Vector (with encoder) |

| Input Voltage | 230V AC ±10% (single-phase); 400V AC ±10% (three-phase); 50/60Hz |

| Output Current | 3A – 30A (continuous); 45A (peak, 60s) |

| Communication Interfaces | RS-485 (Modbus RTU); Ethernet (Modbus TCP/IP optional with adapter) |

| I/O Configuration | 6 digital inputs; 4 digital outputs (relay, 5A); 2 analog inputs (4-20mA/0-10V); 1 analog output (4-20mA) |

| Protection Features | Overcurrent, overload, overvoltage, undervoltage, overheating, phase loss, ground fault |

| Physical Dimensions (H×W×D) | 220mm × 160mm × 100mm; Weight: 1.2kg |

| Operating Temperature Range | -10°C to +50°C (ambient); -25°C to +70°C (storage) |

| Certifications | CE, UL 61800-5-1, IEC 61800-5-1, RoHS |

GE DS200DMCBG1A

Product introduction

GE DS200DMCBG1A is a high-performance digital motor control board designed to manage and protect medium-voltage AC induction motors in industrial automation systems. As a key component in GE’s motor drive ecosystem, GE DS200DMCBG1A integrates advanced control algorithms with robust protection features, enabling precise speed and torque regulation across a wide range of motor sizes (0.75kW to 75kW).

Unlike basic motor controllers that offer only V/F control, GE DS200DMCBG1A provides multiple operating modes—including sensorless and closed-loop vector control—making it suitable for applications requiring high dynamic performance, such as conveyor systems, pumps, and fans. Its flexible I/O configuration allows seamless integration with PLCs, HMIs, and other automation components, while built-in communication ports support remote monitoring and control.

In industrial environments, GE DS200DMCBG1A acts as the “brain” of motor operation, optimizing energy consumption by adjusting voltage and frequency based on load demands. Its comprehensive protection suite prevents motor damage from electrical faults or mechanical overloads, reducing unplanned downtime and maintenance costs. Whether deployed in manufacturing plants, water treatment facilities, or HVAC systems, GE DS200DMCBG1A delivers reliable, efficient motor control tailored to diverse industrial needs.

Core advantages and technical highlights

Multi-Mode Control Flexibility: GE DS200DMCBG1A offers three distinct control modes to match application requirements. V/F control is ideal for simple fans and pumps, providing stable operation with minimal setup. Sensorless vector control delivers precise torque regulation for variable-load applications like mixers or conveyors, maintaining performance without expensive encoders. For high-precision tasks such as robotic arms or winding machines, closed-loop vector control (with encoder feedback) achieves speed accuracy within ±0.01%. This versatility eliminates the need for multiple controller types, simplifying inventory and reducing training requirements for maintenance teams.

Intelligent Energy Optimization: GE DS200DMCBG1A incorporates adaptive energy-saving algorithms that adjust motor voltage and frequency based on real-time load conditions. In a water treatment plant’s pump system, for example, the controller reduces output when demand is low, cutting energy consumption by up to 30% compared to traditional fixed-speed drives. This not only lowers operational costs but also extends motor lifespan by reducing thermal stress during light-load operation. The controller’s power factor correction feature further enhances efficiency by minimizing reactive power draw from the grid.

Comprehensive Protection and Diagnostics: GE DS200DMCBG1A includes a full suite of protective functions that detect and respond to faults in milliseconds. Overcurrent protection prevents damage during mechanical jams, while overheating protection shuts down the motor before windings are damaged. Unique to GE DS200DMCBG1A is its predictive maintenance capability: it continuously monitors motor operating parameters (temperature, current, vibration) and generates alerts for potential issues (e.g., bearing wear) before they cause failures. In a factory setting, this allows technicians to schedule maintenance during planned downtime, avoiding costly unplanned production stops.

Typical application scenarios

GE DS200DMCBG1A is widely used in municipal water treatment plants, where it controls 15kW to 55kW pumps responsible for water distribution and filtration. Operating in sensorless vector mode, the controller adjusts pump speed based on water demand signals from level sensors (connected via its analog inputs). During peak morning usage, GE DS200DMCBG1A increases pump speed to maintain pressure, then reduces speed during low-demand periods—cutting energy costs by an average of $4,000 per pump annually.

The board’s overcurrent protection proved critical when a filter clog caused increased resistance: GE DS200DMCBG1A detected the current spike, shut down the pump, and sent an alarm via Modbus to the plant SCADA system. Technicians cleared the clog and restarted the pump remotely, avoiding damage and limiting downtime to 30 minutes.

In a food processing facility, GE DS200DMCBG1A controls 7.5kW conveyor motors in closed-loop vector mode, using encoder feedback to maintain precise speed synchronization across multiple conveyors. This ensures consistent spacing between packages, reducing product jams and improving packaging line efficiency by 15%. The controller’s stainless-steel-compatible design (when installed in a NEMA 4X enclosure) also withstands the harsh washdown environments typical in food production.

GE DS200DMCBG1A

Related model recommendations

GE DS200DMCAH1A: Lower-power variant of GE DS200DMCBG1A (0.75kW – 15kW); ideal for small conveyors and fans where compact size is prioritized.

GE 531X306H101: Encoder interface module that pairs with GE DS200DMCBG1A for closed-loop vector control; provides high-resolution speed feedback.

GE IC693ALG392: Analog input module that expands GE DS200DMCBG1A’s sensor connectivity; adds 8 additional 4-20mA inputs for complex systems.

GE DS200EXPSG1A: Power supply module that provides stable 24V DC to GE DS200DMCBG1A and peripheral sensors; ensures reliable operation during voltage fluctuations.

GE Proficy Machine Edition: Configuration software for GE DS200DMCBG1A; allows parameter setup, control mode selection, and diagnostic monitoring.

GE DS200TERMG5: Terminal block kit designed for GE DS200DMCBG1A; includes insulated terminals for high-voltage connections and signal wiring.

GE 22A-D6P0N104: Power module compatible with GE DS200DMCBG1A; handles power conversion for 400V AC three-phase motor applications.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing GE DS200DMCBG1A, verify the motor rating (voltage, current, power) matches the controller’s specifications. Ensure the mounting location is within -10°C to +50°C and protected from direct moisture or dust (use NEMA 4 enclosure for harsh environments). Required tools include a torque screwdriver (0.8 – 1.2 N·m), wire strippers (14 – 22 AWG), phase meter, and insulation tester. Safety precautions: Disconnect all power sources and apply lockout/tagout. Mount GE DS200DMCBG1A on a grounded metal surface using M5 screws, ensuring 100mm clearance for ventilation. Connect motor leads to output terminals (verify phase sequence) and power supply to input terminals, using appropriate wire gauges for current rating.

Maintenance suggestions: For daily operation, monitor GE DS200DMCBG1A’s status LEDs (green = normal, red = fault) and check HMI alarms. Every 3 months, inspect connections for tightness (retorque terminals to 1.0 N·m) and clean heatsinks with compressed air to remove dust buildup. Calibrate analog inputs annually using a precision 4-20mA signal generator. If a fault occurs, refer to the error code displayed on the controller’s LED panel: overcurrent faults often indicate mechanical issues (check for jams), while overheating may require cleaning or fan replacement. Replace GE DS200DMCBG1A with a GE-approved spare only if internal components are damaged—third-party replacements may not meet safety certifications.

Service and guarantee commitment

GE DS200DMCBG1A is backed by a 36-month manufacturer’s warranty from General Electric, covering defects in materials, workmanship, and performance under normal operating conditions (per UL 61800-5-1 standards). If GE DS200DMCBG1A fails within the warranty period, GE provides a replacement unit within 72 hours of fault confirmation, minimizing downtime for critical applications.

GE offers 24/7 technical support for GE DS200DMCBG1A through its global network of industrial automation specialists, available via phone or email to assist with installation, programming, and troubleshooting. Customers receive free access to firmware updates for 2 years post-purchase, ensuring compatibility with evolving system requirements. For enhanced support, GE’s Motor Control Service Package includes annual on-site inspections, calibration verification, and performance optimization of GE DS200DMCBG1A—demonstrating GE’s commitment to long-term reliability and customer satisfaction.