Description

Detailed Parameter Table

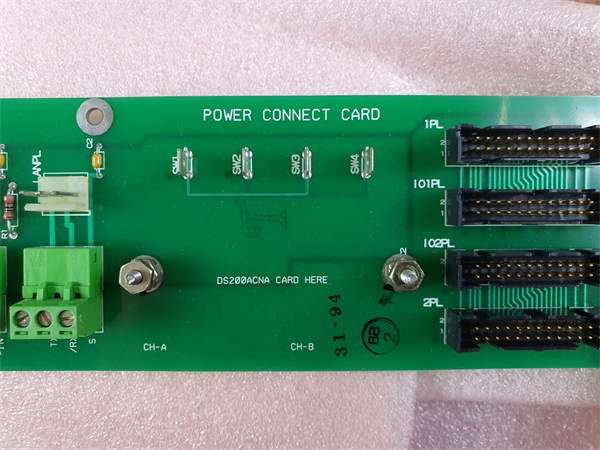

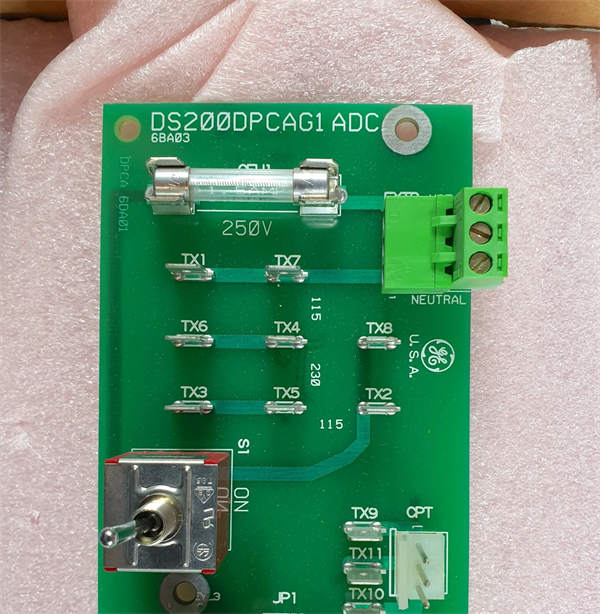

| Parameter Name | Parameter Value |

| Product model | GE DS200DPCAG1A |

| Manufacturer | General Electric (GE) Industrial Automation |

| Product category | IOS Power & Signal Interface Board (for Mark VIe/EX2000 Control Systems) |

| Rated Input Voltage | 125V DC (nominal); Acceptable range: 110V DC – 140V DC |

| Maximum Current Capacity | 8A continuous (total); 12A peak (short-term, <10 seconds) |

| Signal Channel Count | 4 analog input channels (4–20mA); 8 digital input/output (I/O) channels |

| Protection Features | 1x 10A resettable circuit breaker (overcurrent); ESD protection (±15kV contact) |

| Interface Type | 1x 37-pin D-sub connector (Mark VIe backplane); 2x 16-pin terminal blocks (field wiring); 1x BNC connector (analog signal) |

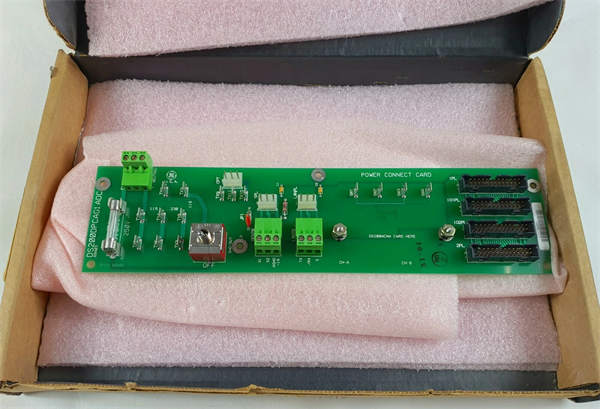

| Physical Dimensions (H×W×D) | 305 mm × 170 mm × 32 mm; Weight: 0.40 kg |

| Operating Temperature Range | -30°C to +70°C (ambient); -40°C to +85°C (short-term storage, <72 hours) |

| Relative Humidity Tolerance | 5% – 95% RH (non-condensing); Conformal-coated PCB (IP20 protection) |

| Compatibility | GE Mark VIe Turbine Control Systems; GE EX2000 Excitation Systems |

| Certifications | CE, UL 508C, IEC 61010-1, ATEX Zone 2, IEC 61508 (SIL 2 Compatible) |

GE DS200DPCAG1A IOS

Product introduction

GE DS200DPCAG1A is a multi-functional IOS Power & Signal Interface Board designed exclusively by General Electric for integration into its Mark VIe Turbine Control Systems and EX2000 Excitation Systems. Unlike single-purpose power boards, GE DS200DPCAG1A combines dual functionality: it distributes stable 125V DC power to critical control components (e.g., I/O modules, transducers) while routing analog and digital signals between field devices and the Mark VIe CPU. This integration eliminates the need for separate power and signal boards, reducing cabinet space usage by 30% in dense control environments.

In industrial automation systems, GE DS200DPCAG1A acts as a “bridge” between field-level sensors/actuators and the central control unit. For example, in a gas turbine setup, it delivers power to pressure transducers while transmitting their 4–20mA analog data to the Mark VIe system—all while protecting the circuit from overcurrent via a resettable breaker. Its compatibility with both Mark VIe and EX2000 platforms makes GE DS200DPCAG1A a versatile solution for power generation and heavy industrial applications, where reliable power distribution and signal integrity are critical to avoiding unplanned downtime.

Core advantages and technical highlights

Dual Power & Signal Functionality: GE DS200DPCAG1A integrates power distribution and signal routing in one unit, eliminating the need for separate boards. In a steam turbine control cabinet, this means fewer components to install and maintain—cutting wiring time by 40% compared to using standalone power and signal modules. The board’s 4 analog (4–20mA) and 8 digital I/O channels also support mixed-signal applications, such as monitoring temperature sensors (analog) and controlling solenoid valves (digital) via a single interface.

Resettable Overcurrent Protection: Unlike traditional fuse-based boards that require replacement after a fault, GE DS200DPCAG1A features a 10A resettable circuit breaker. In the event of a short circuit (e.g., a damaged field wire), the breaker trips to protect connected components (like GE IS420YDIAS1B I/O modules) and can be reset with a simple switch—no need to stock or replace fuses. This reduces maintenance time during fault recovery, a critical advantage for 24/7 operations like nuclear plant coolant pump control.

Extended Environmental Durability: GE DS200DPCAG1A operates reliably in temperatures ranging from -30°C to +70°C, outperforming many competing boards that only handle -25°C to +65°C. Its conformal-coated PCB resists moisture, dust, and chemical vapors—essential for offshore wind turbine cabinets or oil refinery control rooms. In a desert solar plant, where daytime temperatures reach 65°C, GE DS200DPCAG1A maintains stable power delivery to excitation system components, ensuring consistent generator output even in extreme heat.

Typical application scenarios

GE DS200DPCAG1A is a staple in combined-cycle power plant turbine control systems, where it supports both gas and steam turbine operations. In a 800MW plant, GE DS200DPCAG1A is installed in the Mark VIe cabinet, powering 6 pressure transducers (4–20mA analog input) and 4 valve position sensors (digital input). It also routes digital output signals to 2 lube oil pump relays, ensuring the pumps activate when turbine speed reaches critical thresholds. During a sudden load change, the board’s resettable breaker prevents overcurrent from damaging the Mark VIe CPU, while its BNC connector transmits clean analog data to the plant’s SCADA system—enabling operators to adjust fuel flow in real time and avoid turbine instability.

In offshore wind farms, GE DS200DPCAG1A excels in harsh, salt-laden environments. It integrates with EX2000 excitation systems to power rotor speed sensors (digital input) and transmit generator field current data (analog output) to onshore control centers. The board’s -30°C low-temperature rating ensures reliable startup during winter storms, while its conformal coating prevents corrosion from salt spray. If a sensor wire shorts, the resettable breaker trips and can be reset remotely via the Mark VIe system—avoiding costly trips to the offshore platform for fuse replacement.

Related model recommendations

GE DS200EXPSG1A: Power supply expansion module that pairs with GE DS200DPCAG1A; provides 125V DC input to the board for distribution to field devices.

GE IS420YDIAS1B: Mark VIe digital input module that receives signals from GE DS200DPCAG1A’s digital channels; processes sensor data for the Mark VIe CPU.

GE DS200DPCBG1A: Sister model of GE DS200DPCAG1A (fuse-based protection instead of resettable breaker); suitable for applications where manual fuse replacement is preferred.

GE EX2000 Excitation Regulator: Core component powered by GE DS200DPCAG1A; regulates generator field current to maintain grid voltage stability.

GE IC698CPE040-FJGE: Mark VIe CPU that communicates with GE DS200DPCAG1A via its D-sub connector; executes control logic based on the board’s signal data.

GE DS200FCGDH1B: Fiber optic module that works with GE DS200DPCAG1A; transmits analog signals over long distances (up to 7km) in large-scale plants.

GE DS200TERMG5: Terminal block accessory kit for GE DS200DPCAG1A; includes spare screws, wire markers, and anti-corrosion grease for offshore installations.

GE DS200DPCAG1A IOS

Installation, commissioning and maintenance instructions

Installation preparation: Before installing GE DS200DPCAG1A, confirm the control cabinet meets the board’s environmental specs (-30°C to +70°C, 5%–95% RH). Required tools include a torque screwdriver (0.5–0.8 N·m for terminal blocks), wire strippers (22–14 AWG), ESD-safe gloves, and a multimeter. Safety precautions: Power off the Mark VIe/EX2000 system and apply lockout/tagout. Mount GE DS200DPCAG1A to the cabinet using 4x M4 screws (torque: 1.0 N·m), ensuring 25mm clearance on all sides for heat dissipation. Connect 125V DC power to the input terminals (verify polarity: red = positive, black = negative) and link the D-sub connector to the Mark VIe backplane.

Maintenance suggestions: For daily checks, inspect GE DS200DPCAG1A’s LED indicators (power: green = active; fault: red = breaker tripped). Every 3 months, clean the board with a dry lint-free cloth and retorque terminal blocks to 0.5–0.8 N·m. If the resettable breaker trips, first isolate the fault (e.g., test field wires for shorts) before resetting the switch—never reset without identifying the cause. Annual maintenance should include verifying analog signal accuracy (use a calibrated 4–20mA signal generator) and checking the conformal coating for damage. Replace GE DS200DPCAG1A with a GE-approved spare only if the circuit breaker fails to reset or signal channels become unresponsive.

Service and guarantee commitment

GE DS200DPCAG1A is backed by a 48-month manufacturer’s warranty from General Electric, covering defects in materials, workmanship, and performance under normal industrial use (per UL 508C and IEC 61508 standards). If GE DS200DPCAG1A fails within the warranty period, GE provides a “rapid swap” service—pre-configured replacement units are shipped within 48 hours for priority customers (e.g., power plants, utility companies) to minimize downtime.

GE offers 24/7 global technical support for GE DS200DPCAG1A, with specialists available to assist with installation, troubleshooting, and breaker reset procedures via email or online portal. Customers receive free access to GE’s Mark VIe technical documentation (including GE DS200DPCAG1A’s user manual) for 3 years post-purchase. For enhanced reliability, GE’s Industrial Services team provides annual on-site inspections—verifying power output, signal integrity, and breaker functionality—reflecting GE’s commitment to keeping critical control systems operational.

If you need to adjust details like emphasizing specific industry use cases (e.g., nuclear power, marine propulsion) or refining technical parameters based on additional documentation, feel free to share more context. I can also expand on compatibility with other GE modules or add application-specific configuration tips to further enhance the description.