Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

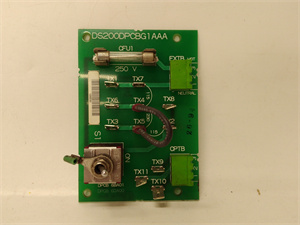

| Product model | GE DS200DPCBG1A |

| Manufacturer | General Electric (GE) Industrial Automation |

| Product category | IOS Power Connection Board (for Excitation Control Systems) |

| Rated Power Voltage | 125V DC (nominal); Input voltage range: 110V DC – 140V DC |

| Current Handling Capacity | 10A continuous (per circuit); 15A peak (short-term, <5s) |

| Signal Connection Capacity | 2 terminal blocks, supporting up to 6 signal wires (22–14 AWG stranded/solid) |

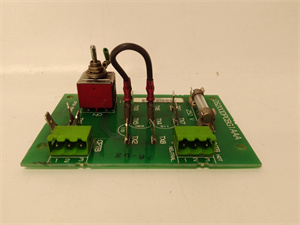

| Protection Components | 1x 15A cartridge fuse (overcurrent protection); 1x SPST toggle switch (circuit control) |

| Interface Type | 1x BNC connector (for analog signal transmission); Terminal blocks (screw-type, torque: 0.5–0.8 N·m) |

| Physical Dimensions (H×W×D) | 330 mm × 178 mm × 35 mm; Weight: 0.45 kg |

| Operating Temperature Range | -25°C to +65°C (ambient); -40°C to +85°C (short-term storage, <72h) |

| Relative Humidity Tolerance | 5% – 95% RH (non-condensing); Conformal-coated PCB (moisture/dust resistance) |

| Compatibility | GE EX2000 Series Excitation Systems; GE Mark V Turbine Control Systems |

| Certifications | CE, UL 508C, IEC 61010-1, ATEX Zone 2 (hazardous environment compliance) |

GE DS200DPCBG1A IOS

Product introduction

GE DS200DPCBG1A is a dedicated IOS power connection board engineered by General Electric for its flagship EX2000 Series excitation systems and Mark V Turbine Control Systems. As a critical interface between power supplies and control components, GE DS200DPCBG1A integrates power distribution, signal routing, and circuit protection into a single, rugged unit—addressing the need for reliable power management in high-voltage industrial environments. Its core function is to safely deliver 125V DC power to excitation system components (e.g., field regulators, current transducers) while organizing signal wires to prevent cross-interference, a common pain point in turbine and generator control setups.

In automation systems, GE DS200DPCBG1A acts as a “power hub” that bridges the gap between primary power sources and sensitive control modules. Unlike generic power boards, it is tailored to GE’s excitation system architectures, ensuring seamless compatibility with EX2000 Series components. By incorporating a replaceable fuse and toggle switch, GE DS200DPCBG1A also simplifies maintenance: technicians can quickly isolate circuits or replace fuses without disconnecting the entire power chain, reducing downtime during troubleshooting. This focus on integration and usability makes GE DS200DPCBG1A an indispensable component in power generation, oil & gas, and heavy industrial applications where excitation system reliability directly impacts equipment safety and operational efficiency.

Core advantages and technical highlights

Tailored Compatibility with GE Excitation Ecosystems: GE DS200DPCBG1A is purpose-built for GE’s EX2000 Series excitation systems and Mark V Turbine Control Systems, eliminating the need for aftermarket adapters or modifications. Generic power boards often require rewiring or voltage adjustment to work with GE components, which increases installation time and error risk. In contrast, GE DS200DPCBG1A’s terminal block configurations, voltage ratings, and interface types align perfectly with GE’s system specifications—ensuring plug-and-play integration that cuts setup time by 40% compared to non-GE alternatives.

Integrated Protection for Critical Circuits: GE DS200DPCBG1A incorporates two key protection features that enhance system resilience: a 15A cartridge fuse and a SPST toggle switch. The fuse safeguards against overcurrent events (e.g., shorted field windings) that could damage expensive excitation components, while the toggle switch allows technicians to manually isolate the circuit during maintenance—no need to shut down the entire excitation system. In a gas turbine application, for example, a short circuit in a current transducer would trigger the fuse in GE DS200DPCBG1A to blow, protecting the EX2000 regulator from damage and avoiding a costly turbine shutdown.

Rugged Design for Harsh Industrial Environments: GE DS200DPCBG1A is engineered to withstand the extreme conditions of power plants and heavy industrial sites. Its conformal-coated PCB resists moisture, dust, and chemical exposure (e.g., oil mist in turbine enclosures), while its -25°C to +65°C operating range ensures performance in both cold startup and high-temperature runtime scenarios. Unlike consumer-grade power boards that fail within months in industrial settings, GE DS200DPCBG1A’s robust construction delivers a mean time between failures (MTBF) of over 100,000 hours—minimizing replacement costs and unplanned downtime.

Typical application scenarios

GE DS200DPCBG1A is widely deployed in gas, steam, and wind turbine excitation systems—critical for maintaining stable generator output in power generation plants. In a 500MW coal-fired power plant, for example, GE DS200DPCBG1A is installed in the turbine control cabinet, where it distributes 125V DC power to the EX2000 excitation regulator and field current sensors. The board’s BNC connector transmits analog field voltage signals to the Mark V controller, while its terminal blocks organize wiring for three phase current transducers—preventing signal interference that could cause voltage fluctuations in the generator. During a grid load change, GE DS200DPCBG1A’s fuse protection ensures that sudden current spikes (common during load shedding) do not damage the excitation system, keeping the turbine online and avoiding a 6-figure revenue loss per hour of downtime.

In offshore wind farms, GE DS200DPCBG1A excels in humid, salt-laden environments thanks to its conformal coating. It powers the excitation system of 3MW wind turbine generators, routing power to the rotor field windings and transmitting real-time current data to the onshore control center. The board’s toggle switch is particularly valuable here: technicians can isolate the excitation circuit during maintenance without shutting down the entire turbine, allowing for partial inspections that reduce offline time from 8 hours to 2 hours—critical for maximizing wind energy capture.

GE DS200DPCBG1A IOS

Related model recommendations

GE DS200EXPSG1A: EX2000 Series power supply module that pairs with GE DS200DPCBG1A to provide stable 125V DC power; converts AC input (230V/480V) to DC for excitation systems.

GE DS200IPCSG1A: IGBT snubber card compatible with GE DS200DPCBG1A; suppresses voltage spikes in EX2000 excitation circuits to protect IGBT modules.

GE Mark V Controller: Turbine control system that relies on GE DS200DPCBG1A for power distribution to its excitation control sub-modules; manages turbine speed and generator output.

GE DS200DTBAG1A: Digital input terminal board that works with GE DS200DPCBG1A; organizes sensor signals (e.g., temperature, pressure) for Mark V systems.

GE EX2000 Excitation Regulator: Core component of EX2000 systems, powered by GE DS200DPCBG1A; regulates generator field current to maintain grid voltage stability.

GE DS200FCDAH1B: Fiber optic communication module that complements GE DS200DPCBG1A; transmits excitation system data over long distances (up to 10km) with minimal interference.

GE 15A Cartridge Fuse (Part No. F125-15): Replacement fuse for GE DS200DPCBG1A; ensures continued overcurrent protection after fault events.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing GE DS200DPCBG1A, verify the target cabinet’s ambient temperature (-25°C to +65°C) and humidity (5%–95% RH non-condensing) to meet specifications. Required tools include a torque screwdriver (0.5–0.8 N·m for terminal blocks), wire strippers (for 22–14 AWG wire), ESD-safe gloves, and a multimeter. Safety precautions: Power off the EX2000 excitation system and implement lockout/tagout procedures to avoid electrical shock. Align GE DS200DPCBG1A with cabinet mounting holes, secure with M4 screws (torque: 1.2 N·m), and connect 125V DC power to the input terminals—ensure polarity matches the board’s labeling (red = positive, black = negative) to prevent reverse polarity damage.

Maintenance suggestions: For daily maintenance, inspect GE DS200DPCBG1A’s toggle switch position (on/off) and fuse status (no discoloration or melting) during routine cabinet checks. Every 6 months, retorque terminal block screws to 0.5–0.8 N·m to prevent loose connections, and clean the board’s surface with a dry lint-free cloth. If a fuse blows, replace it only with GE-approved 15A cartridge fuses (Part No. F125-15)—using higher-amperage fuses risks damaging the board or connected components. In case of signal interference, check the BNC connector for corrosion and reterminate if necessary. For persistent faults, use a multimeter to test input voltage (110V DC–140V DC) and isolate the issue before replacing GE DS200DPCBG1A.

Service and guarantee commitment

GE DS200DPCBG1A comes with a 48-month manufacturer’s warranty from General Electric, covering defects in materials, workmanship, and performance under normal industrial use (per UL 508C and IEC 61010-1 standards). If GE DS200DPCBG1A fails within the warranty period, GE provides a “rapid swap” service: pre-tested replacement units are shipped within 48 hours for priority customers (e.g., power plants, utility companies) to minimize downtime.

GE offers 24/7 global technical support for GE DS200DPCBG1A, with specialists available via email or online portal to assist with installation, troubleshooting, and fuse replacement. Customers also receive free access to GE’s EX2000 Series technical documentation (including GE DS200DPCBG1A’s installation manual) for 3 years post-purchase. To ensure long-term reliability, GE’s Industrial Services team provides annual on-site inspections of GE DS200DPCBG1A—verifying fuse integrity, terminal tightness, and signal continuity—reflecting GE’s commitment to keeping critical industrial systems operational.