Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

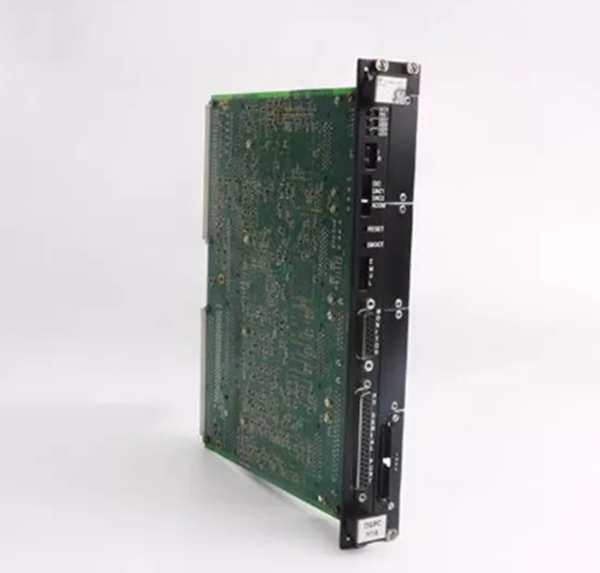

| Product model | GE DS200DSFBG2A |

| Manufacturer | General Electric (GE) Industrial Automation |

| Product category | Digital Signal Filter Board (High-Performance Noise Reduction for Mark VIe Systems) |

| Filter Channels | 16 independent analog input channels with dedicated digital signal processing |

| Input Signal Types | Voltage: ±5V DC, ±10V DC, 0-5V DC, 0-10V DC; Current: 4-20mA DC (via internal shunt) |

| Filter Types | Configurable: Low-pass (1Hz-1kHz), High-pass (1Hz-1kHz), Band-pass (user-defined), Notch (50Hz/60Hz selectable) |

| Filter Resolution | 16-bit ADC with 32-bit floating-point DSP processing |

| Signal-to-Noise Ratio (SNR) | >90dB (typical) after filtering |

| Sampling Rate | Up to 10kHz per channel (configurable in 100Hz increments) |

| Latency | <1ms (filter processing delay at 1kHz sampling) |

| Interface Type | 1x 50-pin D-sub connector (to Mark VIe I/O modules: GE IS420YDIAS1B); 1x 34-pin terminal block (field inputs) |

| Power Requirements | 5V DC (from Mark VIe backplane): 0.6A typical; 0.8A maximum |

| Physical Dimensions (W×H×D) | 130mm × 100mm × 35mm (chassis-mount form factor); Weight: 190g |

| Installation Method | Slot mounting in Mark VIe control chassis (e.g., GE IC698CMX016); 1 slot required |

| Operating Temperature Range | 0°C to 60°C (ambient); -20°C to 70°C (short-term storage, <72 hours) |

| Relative Humidity Tolerance | 5% to 95% RH (non-condensing); Conformal-coated circuit board |

| Protection Features | Input over-voltage protection (up to 30V DC); Reverse polarity protection; ESD protection (±15kV contact) |

| Certifications | CE, UL 508C, IEC 61010-1, ATEX Zone 2, IEC 61508 (SIL 2 compatible) |

| Compatibility | GE Mark VIe ecosystem: GE IC698CPE040-FJGE (CPU), GE DS200DSPCH1A (communication module); Field devices: Pressure transducers, temperature sensors, flow meters |

| Diagnostic Indicators | 16x channel status LEDs (green = active, amber = clipping); 1x power LED (red = 5V present); 1x fault LED (red = processing error) |

| Configuration Tool | GE Proficy Machine Edition v9.0+ (filter parameters, sampling rates) |

GE DS200DSPCH1A

Product Introduction

The GE DS200DSFBG2A is a high-performance digital signal filter board designed specifically for GE’s Mark VIe control system, serving as a critical component in noise-sensitive industrial applications. This specialized board addresses a common challenge in industrial environments: the presence of electrical noise and interference that can corrupt analog signals from sensors and transducers.

By incorporating 16 independent channels of advanced digital filtering, the GE DS200DSFBG2A cleans and conditions raw analog input signals before they reach the main I/O modules and CPU. Its powerful 32-bit floating-point DSP processes each channel individually, allowing for precise customization of filter parameters to match specific signal characteristics and noise profiles.

This module is particularly valuable in power generation, oil and gas, and heavy manufacturing applications where accurate signal measurement is essential for process control, equipment protection, and safety. When integrated with GE IS420YDIAS1B I/O modules and GE DS200DSPCH1A communication modules, it forms a complete signal processing chain that ensures reliable operation even in electrically harsh environments.

Core Advantages and Technical Highlights

Multi-Channel Digital Signal Processing

The GE DS200DSFBG2A features 16 independent channels, each with dedicated digital signal processing capabilities. This allows for simultaneous filtering of multiple diverse signals, each with their own unique filter configurations. For example, in a gas turbine control system, pressure signals might require a 100Hz low-pass filter, while vibration signals need a 500Hz band-pass filter—all handled concurrently without cross-interference. This multi-channel architecture reduces the need for multiple single-purpose filter modules, saving chassis space and simplifying system design.

High-Precision Filtering with Flexible Configuration

With 16-bit ADC resolution and 32-bit floating-point processing, the GE DS200DSFBG2A delivers exceptional signal clarity with a signal-to-noise ratio exceeding 90dB. The board supports multiple filter types (low-pass, high-pass, band-pass, and notch) that can be precisely configured through GE Proficy Machine Edition software. The notch filter, specifically, can be set to 50Hz or 60Hz to eliminate line frequency interference—a common issue in factory environments. This level of customization ensures optimal signal conditioning for virtually any sensor type and application scenario.

Low-Latency Processing for Real-Time Control

Despite its advanced filtering capabilities, the GE DS200DSFBG2A introduces minimal latency (<1ms at 1kHz sampling), making it suitable for time-critical control applications. In safety systems such as turbine overspeed protection or emergency shutdown circuits, this low latency ensures that critical signals are processed quickly enough to trigger appropriate responses within required safety margins. This combination of noise reduction and rapid processing is particularly valuable in systems where both accuracy and responsiveness are essential.

Typical Application Scenarios

Gas Turbine Monitoring Systems

In a combined-cycle power plant, the GE DS200DSFBG2A plays a vital role in turbine health monitoring. It processes signals from 16 different sensors: vibration transducers on bearings, temperature sensors in combustion chambers, and pressure transmitters in fuel lines. The board’s notch filters eliminate 60Hz interference from generator equipment, while low-pass filters remove high-frequency noise from vibration signals. By providing clean, accurate data to the Mark VIe CPU (GE IC698CPE040-FJGE), it enables precise control of turbine operations and early detection of potential issues—helping prevent unplanned shutdowns that could cost hundreds of thousands of dollars per hour.

Oil Refinery Process Control

In an oil refinery’s distillation unit, the GE DS200DSFBG2A conditions signals from temperature and pressure sensors located near large motors and transformers—sources of significant electrical noise. The board’s high-pass filters remove DC drift from pressure transmitters, while band-pass filters isolate the relevant frequency components of level sensor signals. This filtered data is then passed to the GE DS200DSPCH1A communication module for transmission to the central control system. By ensuring accurate measurement of critical process variables, the GE DS200DSFBG2A helps maintain product quality, optimize energy usage, and prevent hazardous conditions.

GE DS200DSPCH1A

Related Model Recommendations

GE IS420YDIAS1B: Mark VIe analog input module that receives filtered signals from the GE DS200DSFBG2A and converts them for processing by the CPU.

GE DS200DSPCH1A: Digital signal processing communication module that works with the GE DS200DSFBG2A to transmit conditioned data to other system components.

GE IC698CPE040-FJGE: Mark VIe CPU that utilizes the clean, filtered data from the GE DS200DSFBG2A for control logic execution and system monitoring.

GE IC698CMX016: Mark VIe backplane module that provides power and communication connectivity for the GE DS200DSFBG2A within the control chassis.

GE DS200EXPSG1A: Power supply module that delivers stable 5V DC to the GE DS200DSFBG2A and other Mark VIe components.

GE DS200DSFAG1A: 8-channel version of the GE DS200DSFBG2A for applications requiring fewer filtered inputs.

GE Proficy Machine Edition v10.0: Software tool used to configure filter parameters, sampling rates, and channel settings on the GE DS200DSFBG2A.

GE DS200TERMG6: Terminal block kit that provides secure connections for field wiring to the GE DS200DSFBG2A.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing the GE DS200DSFBG2A, verify compatibility with the Mark VIe chassis (e.g., GE IC698CMX016) and ensure the operating environment meets specifications (0°C–60°C, 5%–95% RH non-condensing). Required tools include a torque screwdriver (0.4 N·m for chassis mounting), wire strippers (for 22–14 AWG wire), ESD-safe gloves, and a laptop with Proficy Machine Edition software.

Safety precautions: Power off the control chassis and implement lockout/tagout procedures before installation. Handle the board only with ESD-safe gloves to prevent damage from electrostatic discharge. Ensure proper alignment with chassis slot guides when inserting the module, and press firmly until it clicks into place—do not force the module as this may damage backplane connectors.

Commissioning & Maintenance Suggestions

During commissioning, power on the chassis and verify that the GE DS200DSFBG2A power LED illuminates red, indicating proper power supply. Use Proficy Machine Edition to configure filter parameters for each channel based on sensor type and environmental noise characteristics. Perform signal testing by applying known input values and verifying that filtered outputs match expected values within acceptable tolerances.

For ongoing maintenance, regularly inspect the module’s status LEDs to ensure all channels are operating normally (green LEDs) with no fault conditions (red fault LED off). Every six months, verify filter settings and recalibrate if necessary using a calibrated signal generator. Check terminal block connections for tightness and corrosion, retorquing to 0.5–0.8 N·m as needed.

In case of a fault, first check for obvious issues such as loose connections or input overload conditions. Use Proficy Machine Edition to review diagnostic data and identify specific problematic channels. If a hardware failure is suspected, replace the module with a GE-approved spare to maintain system integrity and safety compliance.

Service and Guarantee Commitment

The GE DS200DSFBG2A comes with a 48-month manufacturer’s warranty from GE, covering defects in materials, workmanship, and performance under normal operating conditions. This warranty includes access to GE’s technical support team for troubleshooting assistance.

GE provides 24/7 global technical support for the GE DS200DSFBG2A, with specialists available to assist with installation, configuration, and troubleshooting via phone or email. For priority customers, GE offers expedited replacement service with guaranteed 48-hour delivery of replacement modules to minimize downtime.

Customers also receive free access to software updates for Proficy Machine Edition for the first two years after purchase, ensuring compatibility with the latest system features and improvements. For enhanced support, GE’s Mark VIe Care Program offers annual on-site inspections, calibration verification, and performance testing for the GE DS200DSFBG2A as part of a comprehensive system maintenance package.