Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

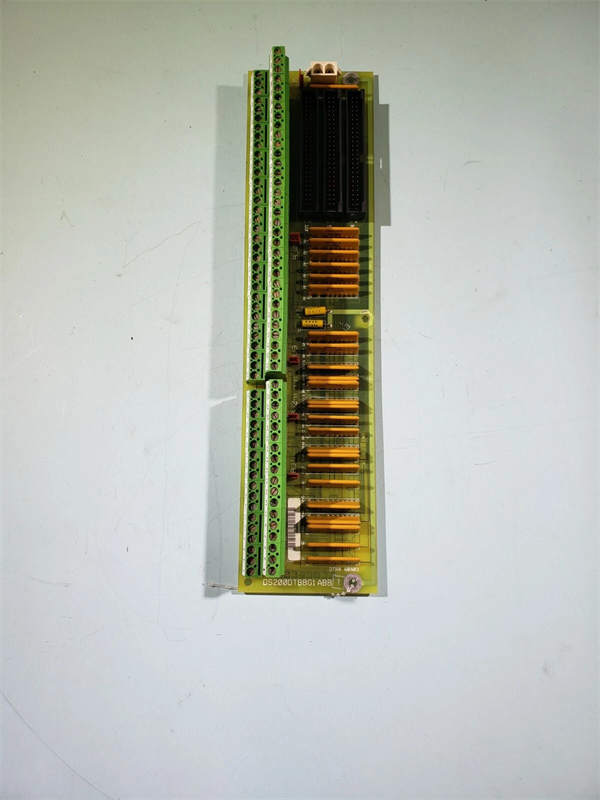

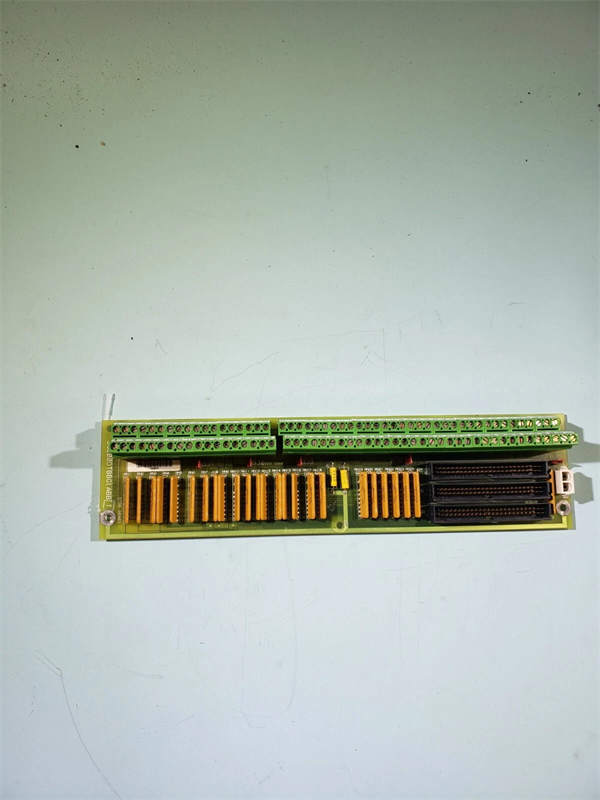

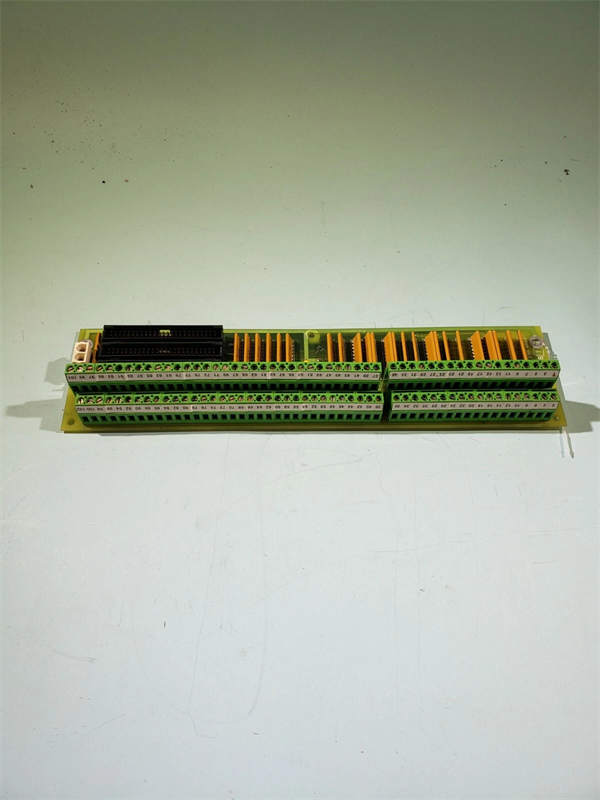

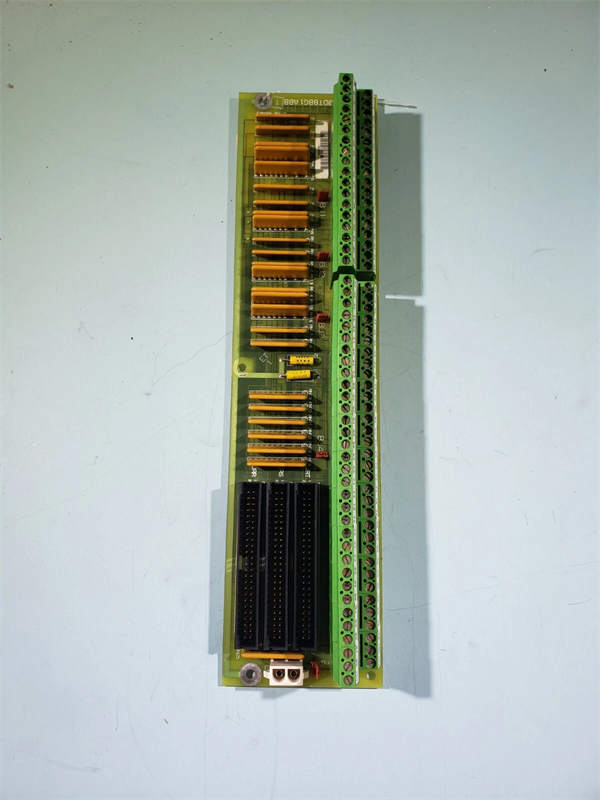

| Product Model | GE DS200IPCSG1A |

| Manufacturer | General Electric (GE) |

| Product Category | Insulated Gate Bipolar Transistor (IGBT) P3 Snubber Card |

| Series | Drive Control |

| Power Requirements | +5V DC, 6A |

| Number of Relay Channels | 12 |

| Power Supply Voltage | 28V DC |

| Mounting | DIN – Rail Mounting |

| Technology | Surface Mount |

| Operating Temperature | -30°C to +65°C |

| Size | 15.9 cm (height) x 17.8 cm (width) |

| Country of Manufacturer | United States |

| Manual | GEH – 6120 |

| Snubber Circuit | Present, designed to dampen voltage spikes during IGBT switching |

| Inductance | Low inductance to reduce electromagnetic interference (EMI) |

| Connector Type | Single 4 – pin connector |

| Adjustment Screws | Six screws labeled C2E – 1 – A, C2E1 – B, C2E – 2 – B, C2E – 2 – A, C1 – A, and C1 – B for hardware adjustments of connected IGBT models |

GE DS200DTBAG1A

Product Introduction

The GE DS200IPCSG1A is an Insulated Gate Bipolar Transistor (IGBT) P3 Snubber Card meticulously crafted by General Electric for applications within the drive control domain. This card plays a pivotal role in power electronics systems, especially those associated with the Mark V or EX2000 series.

IGBTs are widely used in high – power applications due to their ability to handle high voltages and currents. However, during the switching process, they generate voltage spikes and electromagnetic interference (EMI) which can be detrimental to the IGBT itself and other components in the circuit. The DS200IPCSG1A is engineered to mitigate these issues. It acts as a safeguard for IGBT modules by effectively absorbing and dissipating the energy of voltage spikes, thereby enhancing the overall reliability and lifespan of power electronic systems.

Core Advantages and Technical Highlights

Snubber Circuit for Voltage Spike Suppression

At the heart of the DS200IPCSG1A is its snubber circuit, a passive electronic circuit that is crucial for dampening the voltage spikes that occur when an IGBT switches on or off. The circuit consists of a precisely designed combination of capacitors and resistors. When a voltage spike is generated during IGBT switching, the capacitors in the snubber circuit quickly absorb the excess energy. The resistors then dissipate this energy in a controlled manner, preventing the voltage spike from reaching harmful levels. This not only protects the IGBT from potential damage due to over – voltage but also improves the overall performance of the power electronics system. By reducing voltage spikes, the IGBT can operate more efficiently, leading to increased system reliability and potentially lower maintenance costs.

Low Inductance Design for Reduced EMI

The DS200IPCSG1A features a low – inductance design, which is essential for minimizing the level of electromagnetic interference (EMI) generated by the IGBT during operation. In high – power applications, EMI can cause interference with other sensitive electronic components in the vicinity, leading to malfunctions or reduced performance. The low – inductance design of the snubber card helps to keep the current flow smooth and stable, reducing the generation of high – frequency electromagnetic fields. This is particularly important in applications where multiple electronic devices are operating in close proximity, such as in industrial control cabinets or complex power distribution systems. The reduced EMI ensures that the DS200IPCSG1A can co – exist with other components without causing interference issues, contributing to a more stable and reliable overall system.

Adjustable Hardware for IGBT Compatibility

The card is equipped with six adjustment screws labeled C2E – 1 – A, C2E1 – B, C2E – 2 – B, C2E – 2 – A, C1 – A, and C1 – B. These screws enable users to make hardware adjustments to the connected IGBT models. This adjustability provides a high degree of flexibility, allowing the DS200IPCSG1A to be fine – tuned to work optimally with different IGBT modules. For example, in a motor drive application where different IGBTs may be used depending on the motor’s power requirements and operating conditions, the adjustment screws can be used to ensure that the snubber card provides the most effective protection for the specific IGBT in use. However, it is important to note that when making these adjustments using a screwdriver, caution must be exercised. Since there is voltage present in the drive and on the board, power should be turned off before any adjustments are made to avoid the risk of electrical shock or damage to the components.

Typical Application Scenarios

Motor Drives in Industrial Automation

In industrial automation settings, motor drives are used to control the speed and torque of electric motors. IGBTs are commonly employed in motor drives due to their high – power – handling capabilities. The GE DS200IPCSG1A finds extensive use in such applications. For instance, in a large – scale manufacturing plant where multiple conveyor belts are used to transport goods, the motor drives controlling these conveyor belts may utilize IGBTs. The DS200IPCSG1A is installed in the drive control system to protect the IGBTs from voltage spikes generated during the frequent starting and stopping of the motors. By ensuring the reliable operation of the IGBTs, the motor drives can function smoothly, minimizing downtime and ensuring the efficient flow of materials within the plant.

Renewable Energy Systems

Renewable energy systems, such as wind turbines and solar power inverters, also rely on IGBTs for power conversion. In a wind turbine, for example, the IGBTs are used to convert the variable – frequency, variable – voltage output of the generator into a stable, grid – compatible electrical signal. During this conversion process, voltage spikes can occur, which can be harmful to the IGBTs. The DS200IPCSG1A is integrated into the power electronics system of the wind turbine to suppress these voltage spikes. Its low – inductance design also helps in reducing EMI, which is crucial as wind turbines are often equipped with sensitive control and monitoring electronics. In solar power inverters, the DS200IPCSG1A serves a similar purpose, protecting the IGBTs and ensuring the efficient conversion of DC power from solar panels to AC power for grid connection.

GE DS200DTBAG1A

Related Model Recommendations

GE Mark V Series Controllers: The DS200IPCSG1A is specifically designed to work in conjunction with the Mark V series. These controllers are widely used in industrial applications for their high – performance control capabilities. For example, in a gas turbine control system, the Mark V controller can be paired with the DS200IPCSG1A to ensure the reliable operation of the IGBTs in the power electronics circuit that controls the turbine’s speed and power output.

GE EX2000 Series Components: Another series that is compatible with the DS200IPCSG1A is the EX2000 series. In an industrial drive system, components from the EX2000 series, such as power modules or control boards, can be integrated with the DS200IPCSG1A to create a comprehensive and reliable power electronics solution. The combination of these components can provide enhanced performance and reliability in applications where high – power IGBTs are used.

GE IGBT Modules: To fully utilize the capabilities of the DS200IPCSG1A, it can be paired with various GE IGBT modules. These modules are designed to handle different power levels and operating conditions. For a high – power motor drive application, a suitable GE IGBT module can be selected and used in combination with the DS200IPCSG1A to ensure optimal protection and performance. The adjustment screws on the DS200IPCSG1A can be used to fine – tune the snubber card to work effectively with the specific IGBT module in use.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing the GE DS200IPCSG1A, it is essential to ensure that the power to the drive control system is completely turned off. This is a crucial safety measure to prevent the risk of electrical shock. The installation area should be clean and free from dust, moisture, and any other contaminants that could potentially affect the performance of the card. The required tools for installation include a suitable screwdriver for tightening and loosening the screws on the board and the DIN – rail mounting hardware. The DIN – rail on which the card will be mounted should be properly installed and securely fastened in the control cabinet. When handling the DS200IPCSG1A, it is recommended to use anti – static wrist straps to protect the sensitive electronic components on the card from electrostatic discharge.

Commissioning & Maintenance Suggestions

During commissioning, the power to the system can be gradually restored. The first step is to visually inspect the DS200IPCSG1A to ensure that all the connectors are properly seated and that there are no signs of physical damage. Then, using a multimeter, the power supply voltage to the card can be checked to ensure that it is within the specified range of +5V DC. The relay channels on the card can be tested by applying appropriate control signals and verifying that the relays are operating as expected. For regular maintenance, it is advisable to periodically check the tightness of the screws on the board, especially the adjustment screws, to ensure that they have not loosened over time. The card should also be inspected for any signs of overheating, such as discoloration of the components or a burnt smell. If any issues are detected, the power to the system should be turned off immediately, and the necessary repairs or replacements should be carried out. It is important to note that if the adjustment screws need to be adjusted during maintenance, the power should be turned off, and caution should be exercised to avoid any damage to the card or injury to the technician.

Service and Guarantee Commitment

GE offers a comprehensive service and guarantee commitment for the DS200IPCSG1A. The product typically comes with a standard warranty period, which covers any defects in materials or workmanship. In the event that the card fails within the warranty period, GE provides a streamlined process for replacement or repair. Their technical support team is available to assist customers with any installation, commissioning, or maintenance issues. GE also offers training programs for technicians on the proper use and handling of the DS200IPCSG1A, ensuring that customers have the necessary knowledge to make the most of the product. Additionally, GE is constantly working on improving the product and may offer software or firmware updates (where applicable) to enhance the performance and functionality of the DS200IPCSG1A over time.