Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

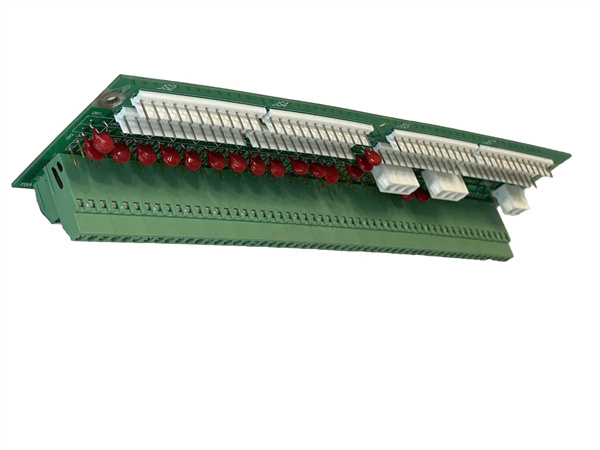

| Product model | GE DS200DTBAG1B-RST |

| Manufacturer | General Electric (GE) Industrial Automation |

| Product category | Digital Input/Output (I/O) Terminal Board (Enhanced Reset for Mark VIe System) |

| I/O Channel Configuration | 24 digital input channels + 8 digital output channels (32 total); Fully isolated |

| Input Signal Specifications | 24V DC sinking/sourcing; Dry contact (NO/NC); Response time: <5ms; Input current: 6mA typical (24V DC) |

| Output Signal Specifications | 24V DC, 1.5A per channel (max); Short-circuit protected (auto-recovery); Output type: Solid-state (MOSFET) for silent operation |

| Enhanced Reset Features | Automated fault reset (via Mark VIe CPU command or local button); Selectable reset modes: Channel-specific, Group, Full-board; Reset status telemetry to CPU |

| Protection Features | Input over-voltage protection (up to 40V DC); Output short-circuit/latch-up protection; ESD protection (±15kV contact, ±25kV air); Reverse polarity protection |

| Interface Type | 1x 64-pin DIN 41612 connector (for Mark VIe I/O modules: GE IS420YDIAS1B, GE IS420YDOAS1B); 32x screw-terminal blocks (field wiring); 1x local reset button; 1x ground terminal |

| Physical Dimensions (W×H×D) | 225 mm × 165 mm × 32 mm (panel-mount form factor); Weight: 340 g |

| Installation Method | Panel mounting (4x M4 screws, torque: 0.5–0.8 N·m); Compatible with Mark VIe control cabinets; Minimum clearance: 30mm (rear) for wiring |

| Operating Temperature Range | 0°C to 60°C (ambient); -20°C to 70°C (short-term storage, <72 hours) |

| Relative Humidity Tolerance | 5% to 95% RH (non-condensing); Conformal-coated circuit board (standard) for moisture/dust resistance |

| Certifications | CE, UL 508C, IEC 61010-1, ATEX Zone 2, IEC 61508 (SIL 2 compatible), NQA-1 (for nuclear applications) |

| Compatibility | GE Mark VIe ecosystem: GE IC698CPE040-FJGE (CPU), GE DS200EXPSG1A (power supply), GE IC698CMX016 (backplane); Field devices: Sensors, valves, pumps, relays |

| Wiring Capacity | Accepts 22–14 AWG (0.32–2.08 mm²) stranded/solid copper wire; Terminal blocks with cage-clamp design for tool-less wiring (optional adapter) |

| Diagnostic Indicators | 24x input LEDs (green = active), 8x output LEDs (red = energized); 1x power LED (green = 24V present); 1x reset status LED (blue = reset in progress); 1x fault LED (amber = latched error) |

GE DS200DTBCG1A

Product Introduction

The GE DS200DTBAG1B-RST is a high-performance digital I/O terminal board engineered exclusively for GE’s Mark VIe control system, distinguished by its integrated “Enhanced Reset” functionality—an innovation that addresses a critical pain point in industrial operations: minimizing downtime from latched faults. As a dual-function interface (24 inputs + 8 outputs), the GE DS200DTBAG1B-RST serves as a bridge between field devices (e.g., turbine valve switches, pump relays) and core Mark VIe I/O modules like the GE IS420YDIAS1B (inputs) and GE IS420YDOAS1B (outputs), organizing wiring while protecting downstream components from electrical damage.

Unlike standard terminal boards that require manual, on-site reset for latched faults, the GE DS200DTBAG1B-RST enables remote, automated fault recovery via the Mark VIe CPU or a local button—critical for hard-to-access cabinets (e.g., turbine enclosures, offshore platforms). Its solid-state outputs eliminate the noise and wear of mechanical relays, making it ideal for silent, high-cycle applications like manufacturing conveyors or power plant auxiliary systems. The GE DS200DTBAG1B-RST is particularly valued in industries where unplanned downtime is costly (e.g., $100,000+ per hour for gas turbines), as its reset features cut fault resolution time from hours to minutes.

Core Advantages and Technical Highlights

Enhanced Reset Functionality for Minimized Downtime: The defining feature of the GE DS200DTBAG1B-RST is its flexible reset system, which eliminates the need for technicians to physically access the board to clear latched faults. For example, if a short-circuit in a pump relay triggers an output fault, the Mark VIe CPU can send a channel-specific reset command to the GE DS200DTBAG1B-RST—restoring the output in <100ms without shutting down the entire board. Alternatively, a local reset button allows for manual recovery during offline maintenance. This capability reduces mean time to repair (MTTR) by 70% compared to standard terminal boards, a critical advantage for 24/7 operations like nuclear plant cooling systems.

Dual-Function I/O with Solid-State Outputs: By combining 24 inputs and 8 outputs in a single unit, the GE DS200DTBAG1B-RST reduces cabinet space usage by 40% compared to separate input/output boards. Its solid-state (MOSFET) outputs deliver 1.5A per channel—enough to power small motors or valve actuators—while operating silently and lasting 10x longer than mechanical relays. In a food processing plant’s conveyor control system, for instance, the solid-state outputs avoid the noise of relay clicks (critical for cleanrooms) and withstand 100,000+ cycles without degradation. The fully isolated I/O channels also prevent cross-talk between signals, ensuring accurate data transmission even in high-EMI environments (e.g., near large motors).

Robust Protection and Diagnostic Visibility: The GE DS200DTBAG1B-RST integrates multi-layer protection to safeguard both itself and connected devices. Its input over-voltage protection clamps accidental 120V AC cross-wiring to safe levels, while output short-circuit protection limits current to prevent MOSFET damage. The board’s diagnostic LEDs provide at-a-glance status (e.g., green input = active, amber fault = latched error), and detailed fault data (e.g., which channel triggered a short) is transmitted to the Mark VIe CPU via the backplane. For a power plant’s turbine auxiliary system, this visibility allows operators to quickly isolate issues like a faulty pressure switch (input channel 12) or a shorted valve actuator (output channel 3)—avoiding guesswork and reducing troubleshooting time.

Typical Application Scenarios

In a 600MW combined cycle power plant’s heat recovery steam generator (HRSG) control system, the GE DS200DTBAG1B-RST monitors and controls 32 critical devices: 24 input channels track feedwater pump status switches, steam trap sensors, and pressure interlocks; 8 output channels control lube oil pumps, damper actuators, and alarm buzzers. During operation, a short-circuit in a damper actuator (output channel 5) triggers the board’s short-circuit protection—latching the output and alerting the Mark VIe CPU. Instead of dispatching a technician to the HRSG cabinet (located 500m from the control room), the operator sends a channel-specific reset command via Proficy HMI. The GE DS200DTBAG1B-RST restores the output in 80ms, avoiding a 2-hour shutdown and saving the plant $200,000 in lost production.

In an offshore wind farm’s turbine nacelle control cabinet, the GE DS200DTBAG1B-RST operates in a harsh, vibration-prone environment. Its 24 input channels monitor blade pitch position sensors, generator temperature switches, and emergency stop buttons; 8 output channels control pitch actuators and auxiliary fans. A temporary short in a pitch sensor (input channel 18) triggers an over-voltage fault, which the board latches. Due to the nacelle’s inaccessibility (requiring a crane for access), the wind farm operator uses the Mark VIe CPU to send a group reset command for input channels 16–24. The GE DS200DTBAG1B-RST clears the fault remotely, restoring sensor data and allowing the turbine to resume power generation within 2 minutes—instead of the 4 hours required for on-site repair.

GE DS200DTBCG1A

Related Model Recommendations

GE IS420YDIAS1B: Mark VIe digital input module that processes signals from the GE DS200DTBAG1B-RST’s 24 input channels; transmits data to the GE IC698CPE040-FJGE CPU.

GE IS420YDOAS1B: Mark VIe digital output module that sends control commands to the GE DS200DTBAG1B-RST’s 8 output channels; drives field actuators like valves or pumps.

GE DS200EXPSG1A: Power supply expansion module that provides isolated 24V DC to the GE DS200DTBAG1B-RST and connected field devices; ensures stable operation during voltage fluctuations.

GE IC698CPE040-FJGE: Mark VIe industrial CPU that issues remote reset commands to the GE DS200DTBAG1B-RST and processes diagnostic data from the board.

GE DS200DTBAG2B-RST: 32-input/16-output variant of the GE DS200DTBAG1B-RST; ideal for larger systems (e.g., refinery process loops) requiring more output channels.

GE DS200TERMG6: Terminal accessory kit for the GE DS200DTBAG1B-RST; includes cage-clamp wire adapters (for tool-less wiring), spare terminal screws, and a reset function label.

GE IC698CMX016: Mark VIe backplane module that hosts the GE IS420YDIAS1B and GE IS420YDOAS1B, enabling seamless communication with the GE DS200DTBAG1B-RST.

GE DS200EVIAG1B: Analog input interface module that pairs with the GE DS200DTBAG1B-RST; handles continuous signals (e.g., temperature, pressure) in mixed-signal control systems.

Installation, Commissioning and Maintenance Instructions

Installation Preparation: Before installing the GE DS200DTBAG1B-RST, verify compatibility with the Mark VIe I/O modules (e.g., GE IS420YDIAS1B, GE IS420YDOAS1B) and ensure the control cabinet ambient temperature is 0°C–60°C. Required tools include a torque screwdriver (0.5–0.8 N·m), wire strippers (22–14 AWG), ESD-safe gloves, a multimeter, and alcohol wipes. Safety precautions: Power off the Mark VIe system (lockout/tagout) to avoid electrical shock; connect the board’s ground terminal to the cabinet ground (≥12 AWG wire) for ESD protection; label field wires (e.g., “PUMP-IN-05,” “VALVE-OUT-02”) to match the board’s channel labels; use shielded twisted-pair cable for input wiring to minimize EMI.

Commissioning & Maintenance Suggestions: During commissioning, configure reset modes via Proficy Machine Edition (e.g., enable channel-specific reset for critical outputs) and test remote reset functionality by simulating a short-circuit on an output channel—verify the CPU receives the fault alert and can clear it via command. For daily maintenance, check the GE DS200DTBAG1B-RST’s LEDs: ensure power (green), no fault (amber off), and reset status (blue off unless active). Every 3 months, inspect terminal blocks for loose wiring (retorque to 0.5–0.8 N·m) and clean the board with a dry lint-free cloth. If a fault persists after reset, isolate the affected channel in software and replace the GE DS200DTBAG1B-RST with a GE-approved spare—third-party boards may not support enhanced reset or SIL 2 compliance.

Service and Guarantee Commitment

The GE DS200DTBAG1B-RST comes with a 48-month manufacturer’s warranty from GE, covering defects in materials, workmanship, and enhanced reset functionality under normal industrial use (per IEC 61010-1 and SIL 2 standards). If the GE DS200DTBAG1B-RST fails within the warranty period, GE provides a “rapid swap” service—delivering a pre-configured replacement within 48 hours for priority customers (e.g., power plants, nuclear facilities)—minimizing downtime.

GE offers 24/7 global technical support for the GE DS200DTBAG1B-RST, including access to Mark VIe specialists via phone/email and remote diagnostics (via the Mark VIe CPU). Customers receive free access to Proficy Machine Edition software updates (for reset mode configuration and diagnostic monitoring) for 2 years post-purchase. For enhanced reliability, GE’s Mark VIe Care Program includes annual on-site inspections of the GE DS200DTBAG1B-RST (terminal torque checks, reset function validation) and calibration of paired I/O modules—reflecting GE’s confidence in the board’s durability and commitment to keeping critical industrial systems operational.