Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | GE DS200DTBCG1A |

| Manufacturer | General Electric (GE) Industrial Automation |

| Product category | Digital Terminal Board (Signal Distribution & Protection for Mark VIe System) |

| Input/Output Channels | 16 digital input channels + 16 digital output channels (32 total) |

| Input Signal Specifications | 24V DC sinking/sourcing; Dry contact (NO/NC); Response time: <10ms |

| Output Signal Specifications | 24V DC, 1A per channel (max); Short-circuit protected (auto-recovery); Output type: Relay (Form C) |

| Protection Features | Input over-voltage protection (up to 40V DC); Output short-circuit protection; ESD protection (±15kV contact) |

| Interface Type | 1x 68-pin DIN connector (for Mark VIe I/O module, e.g., GE IS420YDOAS1B); 32x screw-terminal blocks (field wiring); 1x ground terminal |

| Physical Dimensions (W×H×D) | 230 mm × 170 mm × 32 mm (panel-mount form factor); Weight: 380 g |

| Installation Method | Panel mounting (4x M4 screws); Compatible with Mark VIe control cabinets; Minimum clearance: 40mm (rear) for wiring |

| Operating Temperature Range | 0°C to 60°C (ambient); -20°C to 70°C (short-term storage) |

| Relative Humidity Tolerance | 5% to 95% RH (non-condensing, no moisture ingress) |

| Certifications | CE, UL 508C, IEC 61010-1, ATEX Zone 2, IEC 61508 (SIL 2 compatible) |

| Compatibility | GE Mark VIe ecosystem: GE IS420YDOAS1B (digital output module), GE DS200EXPSG1A (power supply), GE IC698CMX016 (backplane) |

| Wiring Capacity | 22–14 AWG (0.32–2.08 mm²) copper wire; Terminal torque: 0.5–0.8 N·m |

| Diagnostic Indicators | 16x input status LEDs (green = active); 16x output status LEDs (red = energized); 1x power LED (green = 24V present) |

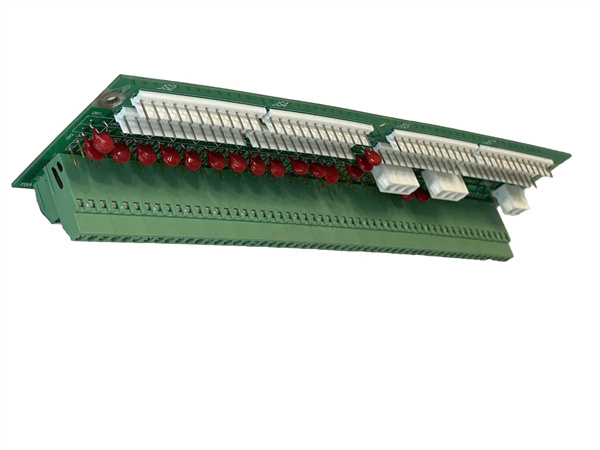

GE DS200DTBCG1A

Product Introduction

The GE DS200DTBCG1A is a versatile digital terminal board designed exclusively for GE’s Mark VIe control system, integrating 16 digital input and 16 digital output channels in a single compact unit. As a critical interface between field devices and core I/O modules, the GE DS200DTBCG1A streamlines wiring in industrial control cabinets while providing essential signal protection.

This dual-function board serves as both a signal aggregator and a protective barrier: it collects input signals from field sensors (e.g., limit switches, pressure interlocks) and distributes output commands to actuators (e.g., solenoid valves, motor starters) while shielding the GE IS420YDOAS1B I/O module from electrical faults. Unlike separate input/output terminal blocks, the GE DS200DTBCG1A reduces cabinet footprint by 40% and simplifies troubleshooting with integrated status LEDs for each channel. It is particularly valuable in mixed-signal applications like turbine auxiliary systems and manufacturing machinery, where space and reliability are paramount.

Core Advantages and Technical Highlights

Integrated Input/Output Design for Space Efficiency: The GE DS200DTBCG1A’s combined 16 inputs and 16 outputs eliminate the need for separate terminal boards, reducing control cabinet space requirements in crowded industrial environments. For example, in a gas turbine auxiliary skid, the board can monitor 16 pump status sensors (inputs) and control 16 valve actuators (outputs) via a single unit, whereas legacy systems would require two separate boards. This integration also simplifies wiring—with a single 68-pin connector linking to the GE IS420YDOAS1B module—cutting installation time by 30%.

Robust Output Protection with Relay Isolation: The GE DS200DTBCG1A’s output channels feature Form C relays (1A rating) with built-in short-circuit protection that automatically recovers after fault clearance. This protects both the board and connected GE IS420YDOAS1B module from damage caused by field wiring errors or actuator failures. For instance, if a solenoid valve connected to Output Channel 8 develops a short, the board limits current to safe levels without affecting other channels—preventing a cascade failure that could shut down an entire turbine lubrication system.

Channel-Level Diagnostics for Rapid Troubleshooting: Each input and output channel on the GE DS200DTBCG1A has an individual LED indicator, providing instant visual confirmation of signal status. Technicians can quickly verify if a pump status signal (Input Channel 3) is active or a valve output (Output Channel 10) is energized without specialized tools. In conjunction with the Mark VIe CPU, the board also reports detailed fault data (e.g., output short-circuit locations) via Proficy Machine Edition, reducing mean time to repair by 50% compared to non-diagnostic terminal blocks.

Typical Application Scenarios

In a 400MW gas turbine’s auxiliary systems control cabinet, the GE DS200DTBCG1A manages critical safety interlocks and control functions: 16 input channels monitor lube oil pressure switches, bearing temperature alarms, and fuel system pressure sensors, while 16 output channels control lube oil pumps, fuel isolation valves, and heater elements. During startup, the Mark VIe CPU uses input data from the GE DS200DTBCG1A to verify all safety conditions are met before energizing the output channels to start the lube oil pump. If a fuel valve output (Channel 5) develops a short, the board’s protection circuitry activates, isolating the fault and alerting operators via the HMI—allowing the turbine to proceed with startup using redundant valves.

In a water treatment plant’s filtration system, the GE DS200DTBCG1A connects to 16 pressure differential switches (inputs) monitoring filter clog status and 16 solenoid valves (outputs) controlling backwash cycles. Its ATEX Zone 2 certification allows installation in areas with potentially explosive atmospheres, while SIL 2 compliance ensures reliable operation in the plant’s safety monitoring loops. The board’s integrated design reduces cabinet size by 35%, making it ideal for the plant’s space-constrained control room. During backwash cycles, operators use the board’s LEDs to visually confirm valve actuation, ensuring proper filter cleaning and maintaining water treatment efficiency.

Related Model Recommendations

GE IS420YDOAS1B: Mark VIe digital output module that interfaces with the GE DS200DTBCG1A; processes control signals from the CPU and drives field actuators.

GE DS200EXPSG1A: Power supply expansion module that provides 24V DC to the GE DS200DTBCG1A and connected field devices.

GE DS200DTBDG1A: 32-input digital terminal board complementary to the GE DS200DTBCG1A; used in systems requiring more input channels than outputs.

GE IC698CMX016: Mark VIe backplane module that hosts the GE IS420YDOAS1B, forming a complete signal chain with the GE DS200DTBCG1A.

GE DS200DTBCG2A: 32-channel (16×16) extended-temperature variant of the GE DS200DTBCG1A (-40°C to 70°C) for harsh environments.

GE IC698CPE040-FJGE: Mark VIe CPU that processes input data from the GE DS200DTBCG1A and generates output commands for field devices.

GE DS200TERMG4: Terminal accessory kit for the GE DS200DTBCG1A; includes spare relay contacts, terminal screws, and wire markers.

GE DS200DTBCG1A

Installation, Commissioning and Maintenance Instructions

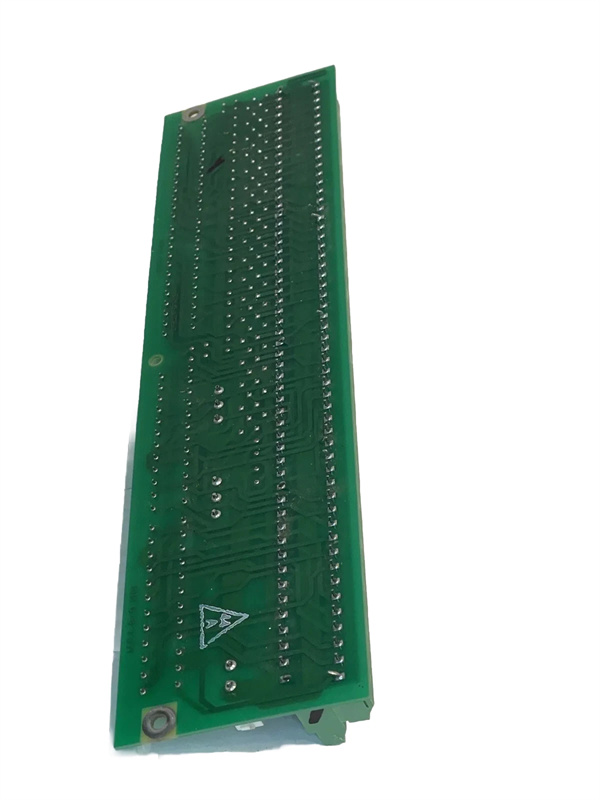

Installation Preparation: Before installing the GE DS200DTBCG1A, verify compatibility with the Mark VIe I/O module (e.g., GE IS420YDOAS1B) and ensure cabinet temperature is 0°C–60°C. Required tools: torque screwdriver (0.5–0.8 N·m), wire strippers (22–14 AWG), ESD gloves, and multimeter. Safety precautions: Power off the system (lockout/tagout); connect the ground terminal to cabinet ground (≥12 AWG); use shielded wire for field connections (ground shield at the board); label input/output wires to match channel numbers (e.g., “IN07-PUMP-PRESSURE”).

Maintenance Suggestions: Daily checks: Verify power LED is green and channel LEDs reflect expected status. Monthly: Inspect terminals for tightness (retorque to 0.5–0.8 N·m) and clean dust with dry cloth. Test output relays annually by energizing each channel and measuring continuity across contacts. If a channel fault occurs (no LED activity), first check field wiring and device; if the issue persists, isolate the channel in software and replace the GE DS200DTBCG1A with a GE-approved spare. Avoid third-party replacements, as they may not meet safety certifications.

Service and Guarantee Commitment

The GE DS200DTBCG1A comes with a 48-month warranty covering defects in materials and workmanship under normal operation. GE provides 24/7 technical support, with rapid replacement (48-hour delivery) for priority customers during warranty periods. Post-warranty, customers can enroll in GE’s Mark VIe Care Program for annual inspections, firmware updates, and calibration services.

GE’s global service network ensures expert assistance for installation, troubleshooting, and maintenance of the GE DS200DTBCG1A, backed by the company’s decades of experience in industrial control systems. This commitment to support reflects GE’s confidence in the board’s reliability and its dedication to minimizing customer downtime.