Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | GE DS200EVIAG1B |

| Manufacturer | General Electric (GE) Industrial Automation |

| Product category | Analog Input Interface Module (Signal Conditioning for Mark VIe System) |

| Input Channel Count | 8 differential analog input channels (configurable per channel) |

| Input Signal Types | Voltage: ±10V DC, ±5V DC, 0–10V DC; Current: 4–20mA, 0–20mA (via shunt resistor); Thermocouple: Type J, K, T, E (optional with cold junction compensation) |

| Measurement Resolution | 16-bit ADC (analog-to-digital converter); ±0.02% full-scale accuracy (25°C) |

| Signal Conditioning | Built-in low-pass filtering (10Hz, 50Hz, 60Hz, 100Hz selectable); Galvanic isolation (1000V AC channel-to-ground) |

| Sampling Rate | 100 samples per second (SPS) per channel; Simultaneous sampling across all 8 channels |

| Interface Type | 1x 37-pin D-sub connector (for Mark VIe I/O module connection, e.g., GE IS420YAIAS1B); 8x 2-pin screw-terminal blocks (field wiring); 1x ground terminal |

| Physical Dimensions (W×H×D) | 200 mm × 150 mm × 35 mm (panel-mount form factor); Weight: 320 g |

| Installation Method | Panel mounting (via 4x M4 screws); Compatible with Mark VIe control cabinets; Minimum clearance: 30mm (top/bottom) for cooling |

| Operating Temperature Range | 0°C to 60°C (ambient); -20°C to 70°C (short-term storage) |

| Relative Humidity Tolerance | 5% to 95% RH (non-condensing, no moisture ingress) |

| Certifications | CE, UL 508C, IEC 61010-1, ATEX Zone 2, IEC 61508 (SIL 2 compatible), NQA-1 (for nuclear applications) |

| Compatibility | GE Mark VIe ecosystem: GE IS420YAIAS1B (analog input module), GE IC698CMX016 (backplane), GE DS200EXPSG1A (power supply); Field devices: Pressure transducers, temperature sensors, flow meters |

| Diagnostic Indicators | 8x channel status LEDs (green = normal, red = over-range); 1x power LED (green = 24V DC present); 1x communication LED (amber = data transmission) |

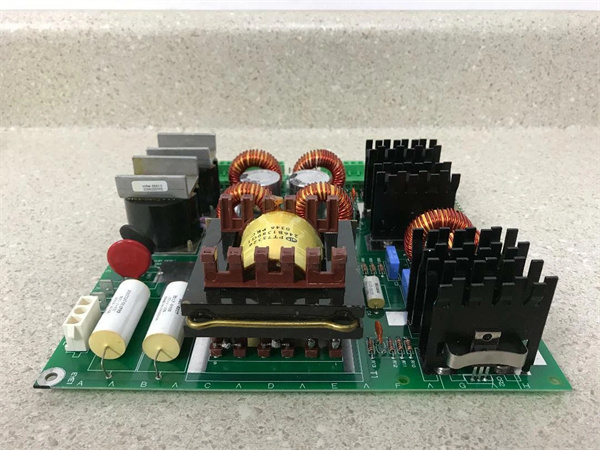

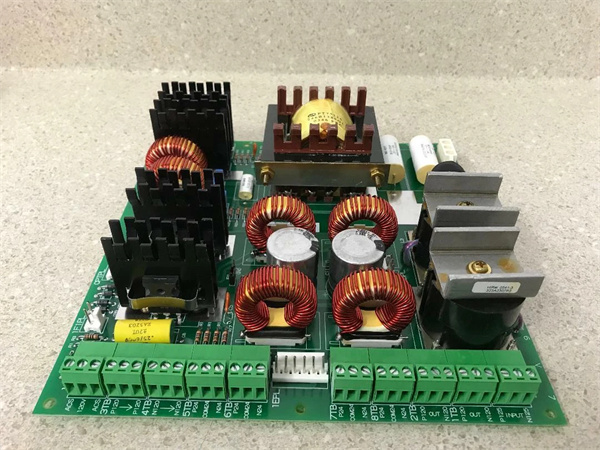

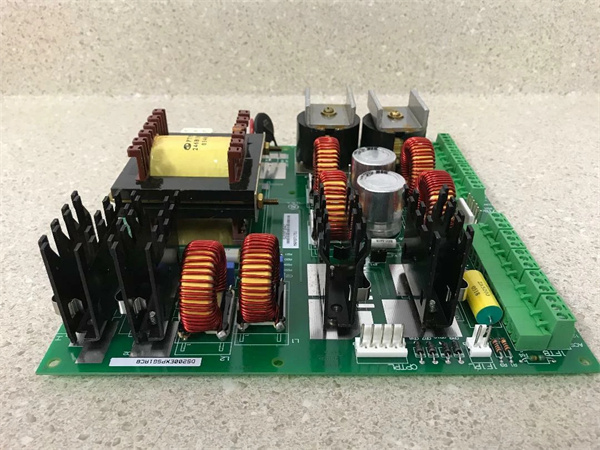

GE DS200EXPSG1A

Product Introduction

The GE DS200EVIAG1B is a precision analog input interface module designed exclusively for GE’s Mark VIe control system, serving as a critical signal conditioning hub between field sensors and core I/O modules. As an integral part of the Mark VIe I/O layer, the GE DS200EVIAG1B addresses a key challenge in industrial automation: converting raw analog signals from sensors (e.g., pressure transducers, temperature probes) into clean, standardized data for processing by modules like the GE IS420YAIAS1B.

Unlike basic terminal blocks, the GE DS200EVIAG1B combines 8-channel signal distribution with advanced conditioning—including galvanic isolation, selectable filtering, and thermocouple cold junction compensation—ensuring measurement accuracy even in high-noise industrial environments. In automation systems, it acts as a “signal translator”: it receives weak or noisy analog signals, filters out electrical interference, isolates channels to prevent cross-talk, and transmits stable data to the Mark VIe I/O module. The GE DS200EVIAG1B is particularly valuable in power generation (turbine temperature monitoring) and chemical processing (pressure/flow control), where analog measurement precision directly impacts system efficiency and safety.

Core Advantages and Technical Highlights

Multi-Signal Compatibility with Per-Channel Configuration: The GE DS200EVIAG1B supports multiple analog signal types (voltage, current, thermocouples) on the same module, with each channel independently configurable via software—eliminating the need for separate interface boards. For example, in a steam turbine control system, 4 channels can process 4–20mA flow meter signals, 2 channels handle ±10V pressure transducer data, and 2 channels monitor Type K thermocouple temperatures (with built-in cold junction compensation). This flexibility reduces module count by 60% compared to fixed-type analog interfaces, simplifying cabinet design and lowering costs.

Precision Measurement with Noise Immunity: Equipped with 16-bit ADCs and selectable low-pass filters (10Hz–100Hz), the GE DS200EVIAG1B delivers ±0.02% full-scale accuracy—critical for applications like boiler pressure control, where small measurement errors can lead to efficiency losses or safety risks. Its galvanic isolation (1000V AC channel-to-ground) blocks ground loops and electrical noise from motors or transformers, ensuring stable readings even in EMI-heavy environments. For a combined cycle power plant, this precision ensures exhaust gas temperature measurements (via thermocouples) are accurate to ±0.5°C, allowing the GE IS420YAIAS1B module to optimize turbine fuel flow and boost efficiency by up to 2%.

Seamless Mark VIe Integration with Diagnostic Capabilities: The GE DS200EVIAG1B is engineered to work natively with the Mark VIe ecosystem, including the GE IS420YAIAS1B analog input module and GE IC698CMX016 backplane. Its channel-level LEDs (green/red) provide at-a-glance status, while detailed diagnostic data (e.g., over-range conditions, open thermocouple) is transmitted to the Mark VIe CPU for alerts via Proficy Machine Edition. This visibility allows technicians to quickly identify issues like a damaged pressure sensor (over-range on Channel 3) or a loose thermocouple wire (open circuit on Channel 7)—reducing troubleshooting time by 50% compared to non-diagnostic interfaces.

Typical Application Scenarios

In a 600MW combined cycle power plant’s heat recovery steam generator (HRSG) control system, the GE DS200EVIAG1B monitors 8 critical analog parameters: 2 channels for 4–20mA feedwater flow meters, 2 channels for ±10V drum pressure transducers, 2 channels for Type K thermocouples (superheater outlet temperature), and 2 channels for 0–10V flue gas oxygen sensors. The module’s 50Hz filtering eliminates noise from the plant’s electrical grid, while galvanic isolation prevents ground loops between the HRSG and turbine control systems. Data from the GE DS200EVIAG1B flows to the GE IS420YAIAS1B module, enabling the Mark VIe CPU to optimize steam production—reducing fuel consumption by 3% annually.

In a chemical processing plant’s reactor control system, the GE DS200EVIAG1B connects to 8 hazardous-area sensors: 4x 4–20mA pressure transmitters (reactor vessel), 2x Type T thermocouples (jacket temperature), and 2x ±5V level transmitters (feed tank). Its ATEX Zone 2 certification allows installation in areas with flammable vapors, while SIL 2 compliance ensures reliable data for the reactor’s safety instrumented system (SIS). If a pressure transmitter fails (over-range), the GE DS200EVIAG1B’s red LED and diagnostic alert trigger an SIS response—closing feed valves within 100ms to prevent overpressure. This combination of precision and safety reduces unplanned shutdowns by 40% compared to legacy analog interfaces.

GE DS200EXPSG1A

Related Model Recommendations

GE IS420YAIAS1B: Mark VIe analog input module that processes conditioned signals from the GE DS200EVIAG1B; transmits digital data to the GE IC698CPE040-FJGE CPU.

GE DS200EXPSG1A: Power supply expansion module that provides isolated 24V DC to the GE DS200EVIAG1B and connected field sensors.

GE DS200EVIAH1B: 16-channel variant of the GE DS200EVIAG1B; ideal for large-scale systems (e.g., refineries) requiring more analog input points.

GE IC698CMX016: Mark VIe backplane module that hosts the GE IS420YAIAS1B, forming a complete signal chain with the GE DS200EVIAG1B.

GE DS200TERMG3: Thermocouple extension cable kit compatible with the GE DS200EVIAG1B; includes shielded Type K/J wires (5m/10m) for noise-free temperature measurements.

GE IC698CPE040-FJGE: Mark VIe industrial CPU that uses data from the GE DS200EVIAG1B (via GE IS420YAIAS1B) to execute control logic for critical processes.

GE DS200EVIAG1B-CAL: Calibration kit for the GE DS200EVIAG1B; includes NIST-traceable signal generators and thermocouple references to verify measurement accuracy.

Installation, Commissioning and Maintenance Instructions

Installation Preparation: Before installing the GE DS200EVIAG1B, verify compatibility with the Mark VIe analog input module (e.g., GE IS420YAIAS1B) and ensure the control cabinet ambient temperature is 0°C–60°C. Required tools include a torque screwdriver (0.5–0.8 N·m for terminal blocks), wire strippers (for 22–16 AWG wire), ESD-safe gloves, and a calibrated multimeter. Safety precautions: Power off the Mark VIe system (lockout/tagout) to avoid electrical shock; use shielded twisted-pair cables for field wiring (ground shield at the module end) to minimize noise; connect the module’s ground terminal to the cabinet ground (≥12 AWG wire); label each channel wire (e.g., “CH01-PRESSURE”) to match sensor types.

Maintenance Suggestions: For daily maintenance, check the GE DS200EVIAG1B’s LEDs—ensure the power LED is green, communication LED flashes amber (data flow), and channel LEDs are green (no faults). Every 6 months, use the GE DS200EVIAG1B-CAL kit to verify accuracy (adjust via Proficy Machine Edition if deviations exceed ±0.05%). Inspect terminal blocks for corrosion (clean with dry cloth if needed) and retorque to 0.5–0.8 N·m. If a channel fault occurs (red LED), first check the sensor and wiring; use a signal generator to inject a known input—if the module fails to respond, isolate the channel in software and replace the GE DS200EVIAG1B with a GE-approved spare. Third-party modules may compromise measurement accuracy or safety compliance.

Service and Guarantee Commitment

The GE DS200EVIAG1B comes with a 48-month manufacturer’s warranty from GE, covering defects in materials, workmanship, and measurement accuracy under normal industrial use (per IEC 61010-1 and SIL 2 standards). If the GE DS200EVIAG1B fails within the warranty period, GE provides a “rapid swap” service—delivering a pre-calibrated replacement within 48 hours for priority customers (e.g., power plants, chemical facilities)—minimizing process downtime.

GE offers 24/7 global technical support for the GE DS200EVIAG1B, including access to Mark VIe analog specialists via phone/email and remote diagnostics (via the Mark VIe CPU). Customers receive free access to Proficy Machine Edition software updates (for calibration and configuration) for 2 years post-purchase. For enhanced reliability, GE’s Mark VIe Care Program includes annual on-site calibration of the GE DS200EVIAG1B and verification of signal conditioning performance—reflecting GE’s confidence in the module’s precision and commitment to keeping critical industrial processes running efficiently.