Description

DS200EXPSG1ACB: Product Overview

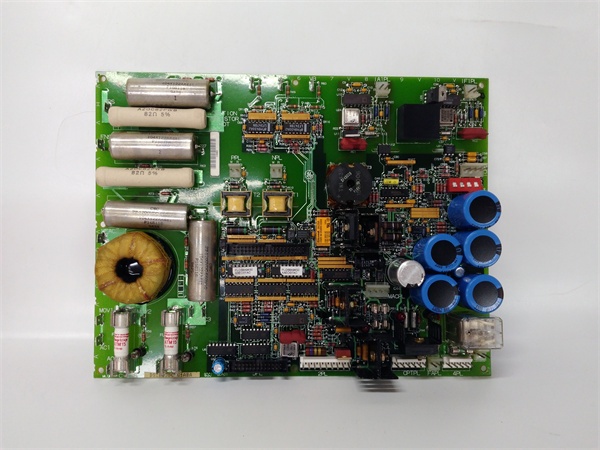

The GE DS200EXPSG1ACB is a bulk power supply board designed exclusively for GE Speedtronic™ Mark V distributed control systems (DCS), the industry standard for gas, steam, and combined-cycle turbine control in power generation. As the “power backbone” of Mark V architectures, it converts incoming AC power (from station batteries or grid sources) into regulated DC voltages, which are distributed to downstream components like excitation systems, I/O modules, and controllers.

Engineered for the demanding conditions of turbine halls, the DS200EXPSG1ACB features a rugged PCB design with normal coating (for dust/moisture resistance) and industrial-grade components (capacitors, fuses) to withstand vibration, temperature fluctuations, and electrical transients. Its legacy compatibility makes it ideal for retrofitting aging Mark V systems—common in power plants operating turbines for 20+ years—where replacing the entire control architecture is cost-prohibitive. Whether powering a 7EA gas turbine or a 9F steam turbine, the DS200EXPSG1ACB ensures reliable power delivery, directly extending the operational life of critical turbine control systems.

Role in Automation Systems

Positioned as a “power hub” in Mark V architectures, the DS200EXPSG1ACB performs three primary functions:

-

Power Conversion: Converts 85–265 V AC input power into +5 V DC and +24 V DC regulated outputs, which are used to power Mark V controllers, I/O modules, and excitation systems.

-

Power Distribution: Distributes DC power to downstream components via 3× 9-pin connectors, ensuring each device receives the correct voltage and current.

-

Fault Protection: Includes overvoltage (e.g., voltage spikes from grid fluctuations), overcurrent (e.g., short circuits in downstream devices), and thermal shutdown (e.g., overheating due to excessive load) protection. These features prevent damage to sensitive electronics and minimize downtime.

Its core value lies in stabilizing power supply—a critical requirement for turbine control, where even minor voltage fluctuations can lead to process instability (e.g., turbine speed variations) or equipment damage (e.g., excitation system failure).

Core Functionality

-

Wide Input Voltage Range: Accepts 85–265 V AC (47–63 Hz), making it compatible with global power standards (e.g., 120 V AC in North America, 230 V AC in Europe). This eliminates the need for additional voltage converters, reducing installation costs.

-

Regulated Outputs: Provides +5 V DC (2 A max) and +24 V DC (5 A max) with tight voltage tolerances (±1%), ensuring consistent power delivery to downstream components. For example, the +24 V DC output powers Mark V I/O modules, while the +5 V DC output powers the controller’s logic circuits.

-

Fault Protection Mechanisms:

-

Overvoltage Protection: Shuts down the board if input voltage exceeds 265 V AC, preventing damage to internal components.

-

Overcurrent Protection: Limits output current to 5 A (for +24 V DC) or 2 A (for +5 V DC), protecting against short circuits in downstream devices.

-

Thermal Shutdown: Automatically turns off the board if the internal temperature exceeds +65°C, preventing overheating and component failure.

-

-

Diagnostic Features:

-

Green LED Indicator: Lights up when the board passes startup diagnostics, indicating normal operation.

-

Reset Button: Clears faults (e.g., overcurrent) without powering down the entire system, reducing downtime during maintenance.

-

-

Modular Design: Fits into standard Mark V PCB racks, enabling easy expansion or replacement. The plug-in design minimizes installation time and effort.

GE DS200SDCIG1A

Technical Specifications

|

Parameter

|

Specification

|

|---|---|

|

Model Number

|

DS200EXPSG1ACB

|

|

Manufacturer

|

General Electric (GE)

|

|

Product Type

|

Bulk Power Supply Board

|

|

Series

|

Mark V (Turbine Control Systems)

|

|

Functional Acronym

|

EXPS (Excitation Power Supply)

|

|

Input Voltage

|

85–265 V AC (47–63 Hz)

|

|

Output Voltage

|

+5 V DC (2 A max), +24 V DC (5 A max)

|

|

Protection Features

|

Overvoltage, overcurrent, short-circuit, thermal shutdown

|

|

Indicators

|

1× Green LED (operational status), 1× Reset button

|

|

Connectors

|

3× 9-pin connectors (for system integration)

|

|

Operating Temperature

|

-30°C to +65°C (industrial-grade)

|

|

Storage Temperature

|

-40°C to +85°C

|

|

Humidity

|

5–95% non-condensing

|

|

Weight

|

~1.88 kg (4.15 lbs)

|

|

Dimensions

|

13.50 inches (L) × 9 inches (W) × 3.50 inches (H)

|

|

Certifications

|

CE, UL (inferred from GE industrial product standards)

|

Core Features & Customer Value

1. Reliable Power Delivery:

The DS200EXPSG1ACB’s regulated outputs and wide input range ensure stable power delivery to Mark V systems, even in areas with unstable power grids. For example, in a power plant, the board can handle voltage fluctuations (85–265 V AC) and still provide clean DC power to the turbine controller, preventing unexpected shutdowns.

2. Fault Tolerance:

Built-in protection mechanisms (overvoltage, overcurrent, thermal shutdown) prevent damage to sensitive electronics, reducing maintenance costs and downtime. For instance, if a short circuit occurs in an I/O module, the overcurrent protection will limit the current draw, preventing the board from failing.

3. Easy Maintenance:

The reset button allows technicians to clear faults without powering down the entire system, reducing downtime. The green LED indicator provides instant visual feedback on the board’s status, simplifying troubleshooting.

4. Cost-Effective Retrofit:

The DS200EXPSG1ACB’s legacy compatibility with Mark V systems means that facilities can upgrade their power supply capabilities without replacing the entire control architecture. This reduces retrofit costs by up to 30% compared to full DCS overhauls, making it an attractive option for power plants with aging Mark V systems.

GE DS200SDCIG1A

Typical Applications

The GE DS200EXPSG1ACB is widely used in industrial automation systems for:

-

Power Generation:

-

Provides power to Mark V turbine control systems in gas/steam power plants, ensuring stable power output and efficient fuel use.

-

-

Combined-Cycle Power Plants:

-

Powers Mark V controllers and I/O modules in combined-cycle plants, where gas and steam turbines are integrated for higher efficiency.

-

-

Industrial Manufacturing:

-

Used in manufacturing facilities to power Mark V-based process control systems, ensuring reliable operation of critical equipment (e.g., pumps, valves).

-