Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | GE DS200FCGDH1A |

| Manufacturer | General Electric (GE) Industrial Automation |

| Product category | Fiber Optic Communication Module (High-Speed Data Link for Mark VIe System) |

| Communication Medium | Multi-mode fiber optic cable (62.5/125μm or 50/125μm); ST or SC connectors (configurable) |

| Data Transfer Rate | 100 Mbps full-duplex; Deterministic latency: <50μs |

| Transmission Distance | Up to 2 km (62.5/125μm fiber); Up to 5 km (50/125μm fiber) |

| Protocol Support | GE SRTP (Secure Real-Time Protocol); Compatible with Mark VIe ControlNet and Ethernet/IP via gateway |

| Interface Type | 2x fiber optic ports (primary/secondary for redundancy); 1x 25-pin D-sub connector (backplane interface); 1x USB port (configuration) |

| Redundancy Features | Automatic failover (≤10ms) between primary/secondary fiber links; Heartbeat monitoring (100ms interval) |

| Physical Dimensions (W×H×D) | 140 mm × 100 mm × 50 mm (chassis-mount form factor); Weight: 220 g |

| Installation Method | DIN rail mounting or panel mounting (2x M3 screws); Compatible with Mark VIe control cabinets; Operating position: Any orientation |

| Operating Temperature Range | 0°C to 60°C (ambient); -40°C to 85°C (extended temperature variant available) |

| Relative Humidity Tolerance | 5% to 95% RH (non-condensing, no moisture ingress) |

| Certifications | CE, UL 508C, IEC 61010-1, ATEX Zone 2, IEC 61508 (SIL 3 compatible), FCC Part 15 |

| Compatibility | GE Mark VIe ecosystem: GE IC698CPE040-FJGE (CPU), GE IC698CMX016 (backplane), GE DS200EXPSG1A (power supply); Fiber optic transceivers: GE FOC-100M-MM |

| Diagnostic Indicators | 2x link status LEDs (green = active, flashing = data transfer); 1x power LED (green = 24V present); 1x redundancy status LED (amber = failover active) |

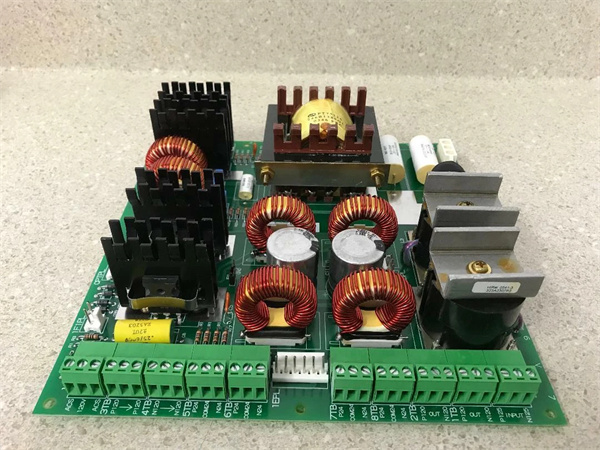

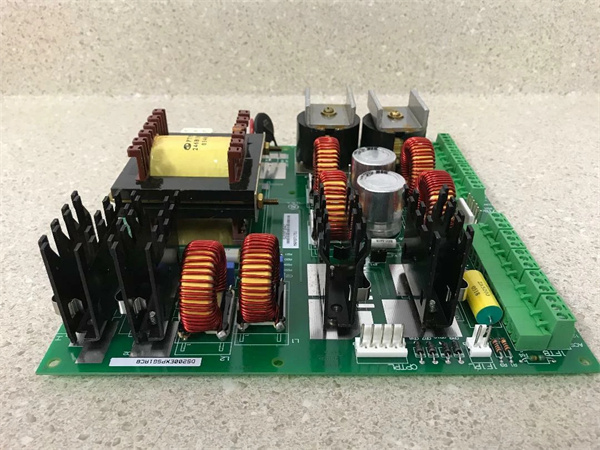

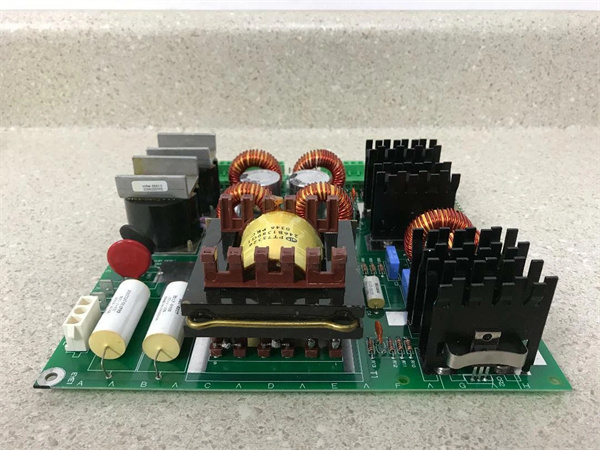

GE DS200EXPSG1A

Product Introduction

The GE DS200FCGDH1A is a high-performance fiber optic communication module designed exclusively for GE’s Mark VIe control system, enabling secure, high-speed data transmission between distributed control components in industrial environments. As a critical connectivity solution in the Mark VIe architecture, the GE DS200FCGDH1A addresses the challenges of long-distance, noise-immune communication—replacing traditional copper cables with fiber optics to eliminate EMI/RFI interference and signal degradation.

This module serves as a “digital backbone” for Mark VIe systems, facilitating real-time data exchange between remote I/O racks, CPUs, and operator stations. Unlike copper-based communication modules, the GE DS200FCGDH1A supports transmission distances up to 5 km while maintaining deterministic latency (<50μs)—critical for time-sensitive applications like turbine control and synchronous machine operation. Its redundant fiber ports ensure uninterrupted communication during cable faults or connector issues, making the GE DS200FCGDH1A indispensable in mission-critical industries such as power generation, oil & gas, and large-scale manufacturing.

Core Advantages and Technical Highlights

EMI/RFI Immunity for Reliable Industrial Communication: The GE DS200FCGDH1A’s fiber optic technology eliminates signal interference from electromagnetic (EMI) and radio frequency (RFI) sources—common in industrial environments with large motors, transformers, or high-voltage equipment. For example, in a steel mill’s rolling mill control system, where EMI from arc furnaces can disrupt copper-based communications, the GE DS200FCGDH1A maintains stable data transmission between the Mark VIe CPU and remote I/O racks monitoring roll pressure and temperature. This immunity reduces communication errors by 99% compared to copper Ethernet modules, preventing costly process interruptions.

Redundant Fiber Links with Ultra-Fast Failover: Equipped with dual fiber ports (primary/secondary), the GE DS200FCGDH1A provides seamless redundancy with automatic failover in <10ms—critical for safety-instrumented systems (SIS) requiring continuous communication. In a nuclear power plant’s reactor coolant pump control system, if the primary fiber link is damaged (e.g., during maintenance), the module instantly switches to the secondary link without data loss, ensuring the Mark VIe CPU maintains visibility of pump vibration and temperature sensors. This redundancy meets IEC 61508 SIL 3 requirements, making the GE DS200FCGDH1A suitable for safety-critical applications where communication downtime could lead to hazardous conditions.

Long-Distance Transmission with Deterministic Performance: The GE DS200FCGDH1A supports data transmission up to 5 km (with 50/125μm fiber) while maintaining 100 Mbps full-duplex speed and <50μs latency—far exceeding the capabilities of copper-based solutions (typically limited to 100m). This makes it ideal for large-scale industrial facilities like refineries or hydroelectric dams, where control components may be distributed across vast areas. For a 2 km-long natural gas pipeline compressor station, the module enables real-time communication between the main control room’s Mark VIe CPU and remote I/O racks at each compressor unit, ensuring synchronized operation and rapid response to pressure fluctuations.

Typical Application Scenarios

In a 1200MW combined cycle power plant, the GE DS200FCGDH1A forms the communication backbone connecting three distributed control cabinets: the main turbine control rack, HRSG (heat recovery steam generator) I/O rack, and auxiliary systems rack. Each cabinet houses a GE DS200FCGDH1A module linked via redundant 50/125μm fiber cables (1.5 km between turbine and HRSG). The modules transmit real-time data—including turbine speed, steam pressure, and fuel flow—at 100 Mbps with <50μs latency, enabling the Mark VIe CPU to optimize combined cycle efficiency. During a scheduled maintenance, accidental damage to the primary fiber cable triggers an immediate failover to the secondary link, with no interruption to power generation.

In an offshore oil platform’s production control system, the GE DS200FCGDH1A connects the central Mark VIe CPU (in the platform’s control room) to remote I/O racks on three wellheads (2 km apart). Its fiber optic medium resists corrosion from saltwater humidity and eliminates ground loop issues common with copper cables in marine environments. The module’s ATEX Zone 2 certification ensures safe operation in potentially explosive atmospheres, while SIL 3 compliance supports the platform’s emergency shutdown system (ESD). If a wellhead pressure sensor detects an anomaly, data travels via the GE DS200FCGDH1A to the CPU, which triggers a shutdown within 200ms—preventing a potential blowout.

GE DS200EXPSG1A

Related Model Recommendations

GE IC698CPE040-FJGE: Mark VIe industrial CPU that communicates with remote I/O racks via the GE DS200FCGDH1A; executes control logic using fiber-transmitted data.

GE FOC-100M-MM: Multi-mode fiber optic transceiver compatible with the GE DS200FCGDH1A; converts electrical signals to optical for long-distance transmission.

GE DS200EXPSG1A: Power supply expansion module that provides 24V DC to the GE DS200FCGDH1A in remote I/O cabinets.

GE DS200FCGDH2A: Single-mode fiber variant of the GE DS200FCGDH1A; supports transmission distances up to 20 km for large-scale facilities (e.g., hydroelectric dams).

GE IC698CMX016: Mark VIe backplane module that hosts the GE DS200FCGDH1A, integrating it into the control system’s communication network.

GE DS200FCG-CAB: Fiber optic cable kit for the GE DS200FCGDH1A; includes 50/125μm multi-mode cables (5m/10m/50m) with ST connectors and protective sheathing.

GE Proficy Machine Edition v9.0: Configuration software for the GE DS200FCGDH1A; enables link setup, redundancy configuration, and diagnostic monitoring.

GE DS200FCGDH1A-EXT: Extended-temperature variant of the GE DS200FCGDH1A (-40°C to 85°C); designed for arctic or desert industrial environments.

Installation, Commissioning and Maintenance Instructions

Installation Preparation: Before installing the GE DS200FCGDH1A, verify compatibility with the Mark VIe backplane (e.g., GE IC698CMX016) and ensure the operating environment is 0°C–60°C. Required tools include a torque screwdriver (0.3–0.5 N·m for mounting), fiber optic cable stripper/crimper, ESD-safe gloves, and an optical power meter. Safety precautions: Power off the control cabinet (lockout/tagout); handle fiber cables carefully to avoid eye injury (use protective glasses); clean connectors with lint-free wipes and isopropyl alcohol before mating; route fiber cables away from high-voltage lines and heat sources (≥300mm clearance).

Maintenance Suggestions: For daily maintenance, check the GE DS200FCGDH1A’s LEDs—ensure power LED is green, link status LEDs are green (active), and redundancy LED is off (normal operation). Monthly, inspect fiber connectors for dirt or damage (clean if necessary) and verify cable strain reliefs are secure. Use an optical power meter quarterly to confirm signal strength (should be -10dBm to -20dBm for multi-mode). If a link fault occurs (flashing link LED), first check cable continuity and connector seating; use the USB port and Proficy Machine Edition to run diagnostic tests. Replace the GE DS200FCGDH1A with a GE-approved spare if hardware failure is confirmed—third-party modules may compromise latency or redundancy performance.

Service and Guarantee Commitment

The GE DS200FCGDH1A comes with a 48-month manufacturer’s warranty from GE, covering defects in materials, workmanship, and communication performance under normal industrial use (per IEC 61010-1 and SIL 3 standards). If the GE DS200FCGDH1A fails within the warranty period, GE provides a “rapid swap” service—delivering a pre-configured replacement within 48 hours for priority customers (e.g., power plants, offshore platforms)—minimizing communication downtime.

GE offers 24/7 global technical support for the GE DS200FCGDH1A, including access to fiber optic communication specialists via phone/email and remote diagnostics (via USB or Mark VIe CPU). Customers receive free access to Proficy Machine Edition software updates (for configuration and monitoring) for 2 years post-purchase. For enhanced reliability, GE’s Mark VIe Care Program includes annual on-site inspections of the GE DS200FCGDH1A (signal strength verification, connector cleaning) and firmware updates—reflecting GE’s confidence in the module’s durability and commitment to keeping critical industrial communication networks operational.