Description

DS200FCRLG1AFC: Product Overview

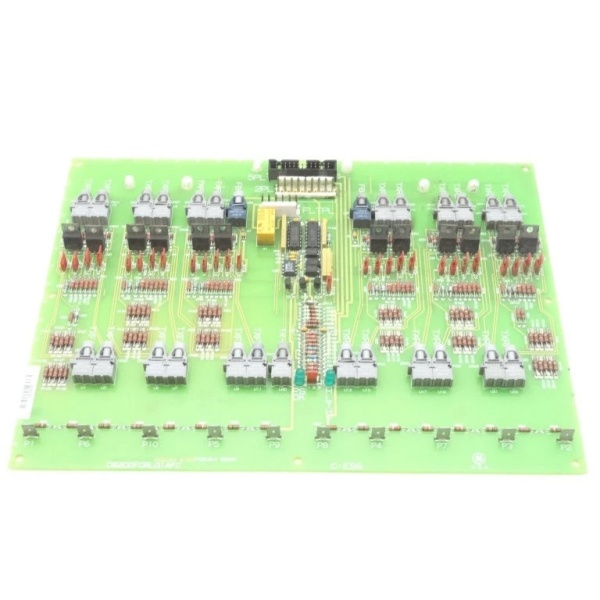

The GE DS200FCRLG1AFC is a firing circuit board designed specifically for GE Speedtronic™ Mark V distributed control systems (DCS), the industry standard for gas, steam, and hydro turbine control in power generation. As part of the Mark V ecosystem, it acts as the “ignition controller” for turbine and generator systems, managing the firing sequences that initiate and maintain combustion. Its primary role is to ensure precise ignition timing and stable firing control—critical for preventing turbine damage during startup and maintaining efficient operation.

Engineered for the demanding conditions of turbine halls, the DS200FCRLG1AFC features a robust PCB layout and high-isolation signal processing to withstand vibration, dust, and electromagnetic interference (EMI). Its legacy compatibility makes it ideal for retrofitting aging Mark V systems—common in power plants operating turbines for 20+ years—where replacing the entire control architecture is cost-prohibitive. Whether used in 7EA gas turbines or 9F steam turbines, the DS200FCRLG1AFC ensures reliable ignition control, directly extending the operational life of critical turbine control systems.

Role in Automation Systems

Positioned as a “critical ignition interface” in Mark V architectures, the DS200FCRLG1AFC performs two primary functions:

-

Firing Sequence Regulation: Controls the timing and duration of ignition pulses sent to the turbine’s combustion chamber, ensuring that fuel is ignited consistently and efficiently.

-

Signal Timing Management: Coordinates with other Mark V components (e.g., drive control boards, I/O modules) to synchronize ignition events with turbine speed and load requirements.

Its core value lies in preventing misfires and unstable combustion—events that can lead to turbine damage, reduced efficiency, or unplanned downtime. By ensuring precise ignition control, the DS200FCRLG1AFC helps power plants maintain high availability and meet strict grid reliability standards.

Core Functionality

-

Precise Ignition Control: The DS200FCRLG1AFC uses advanced timing circuits to regulate firing sequences, ensuring that ignition pulses are delivered at the optimal moment for efficient combustion. This is critical for gas turbines, where even minor timing errors can lead to increased emissions or reduced power output.

-

High-Speed Switching: Supports high-frequency switching (up to system maximum) to accommodate the rapid ignition requirements of modern turbines. This ensures that the turbine reaches full speed quickly and efficiently during startup.

-

Industrial-Grade Durability: Designed to operate in temperatures from 0°C to +70°C, the DS200FCRLG1AFC withstands the extreme conditions of turbine halls (e.g., vibration, dust, moisture). Its robust PCB layout and high-quality components ensure reliable operation even in harsh environments.

-

Legacy Compatibility: Fully compatible with existing Mark V components (e.g., drive control boards, I/O racks), the DS200FCRLG1AFC eliminates the need for costly system upgrades. This makes it an ideal choice for power plants with aging Mark V systems, where replacing the entire control architecture is not feasible.

Technical Specifications

|

Parameter

|

Specification

|

|---|---|

|

Model Number

|

DS200FCRLG1AFC

|

|

Manufacturer

|

General Electric (GE)

|

|

Product Type

|

Firing Circuit Board

|

|

Series

|

Mark V (Turbine Control Systems)

|

|

Compatible System

|

Mark V Digital Excitation System

|

|

Input Voltage

|

120/240 V AC nominal

|

|

Output Voltage

|

Configurable per system requirements

|

|

Switching Frequency

|

High-speed, up to system maximum

|

|

Operating Temperature

|

0°C to +70°C (industrial-grade)

|

|

Storage Temperature

|

-20°C to +85°C

|

|

Relative Humidity

|

10% to 90% non-condensing

|

|

Mounting Method

|

Rack-mounted, Mark V chassis compatible

|

|

Dimensions

|

Approx. 200 × 150 × 50 mm

|

|

Weight

|

~1.2 kg (2.65 lbs)

|

|

Environmental Protection

|

Conformal coating for moisture and dust resistance

|

|

Indicators

|

Status LEDs for operational monitoring

|

|

Safety & Compliance

|

CE, UL, and industry-standard electrical safety certifications

|

DS200FCRLG1AFC

Core Features & Customer Value

1. Reliable Ignition Control:

The DS200FCRLG1AFC’s precise timing circuits ensure that ignition pulses are delivered consistently, preventing misfires and unstable combustion. For example, in a gas power plant, the board can adjust the firing sequence based on turbine speed feedback, ensuring that the turbine starts smoothly and reaches full load quickly.

2. High-Speed Switching:

The board’s support for high-frequency switching accommodates the rapid ignition requirements of modern turbines. This reduces startup time and improves efficiency, which is critical for power plants that need to respond quickly to changes in grid demand.

3. Rugged Industrial Design:

The DS200FCRLG1AFC’s ability to operate in temperatures from 0°C to +70°C makes it suitable for harsh turbine hall environments. Its robust PCB layout and high-quality components protect against vibration and EMI, ensuring reliable operation even in the most demanding conditions.

4. Legacy Compatibility:

Designed to work with existing Mark V components, the DS200FCRLG1AFC eliminates the need for costly system upgrades. This makes it an ideal choice for power plants with aging Mark V systems, where replacing the entire control architecture is not feasible.

Typical Applications

The GE DS200FCRLG1AFC is widely used in industrial automation systems for:

-

Power Generation:

-

Controls firing sequences for gas/steam turbines in power plants, ensuring stable startup and operation.

-

-

Industrial Drives:

-

Used in industrial motor drives (e.g., conveyor belts, pumps) to control ignition timing for combustion engines.

-

-

Retrofit Projects:

-

Ideal for retrofitting aging Mark V systems, where replacing the entire control architecture is cost-prohibitive. The board’s legacy compatibility allows for easy integration with existing components.

-