Description

DS200FHVAG1ABA: Product Overview

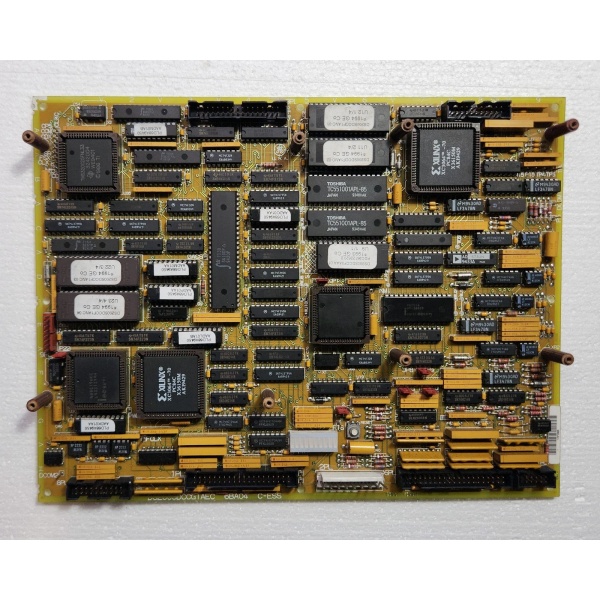

The GE DS200FHVAG1ABA is a high-voltage gate interface board designed for integration into GE’s Mark V series of turbine control systems. As a critical component of power electronic drive assemblies, it enables precise control of high-power semiconductor devices (e.g., GTO thyristors, IGBTs) that are essential for converting alternating current (AC) to direct current (DC) or regulating voltage in turbine applications.

Role in Automation Systems:

Positioned as the “gate control interface” in Mark V drive systems, the DS200FHVAG1ABA performs two primary functions:

-

Gate Signal Generation: Produces high-current pulses to turn power electronic devices on/off, controlling the flow of power to turbine motors or generators.

-

Protection Coordination: Monitors device operation for faults (e.g., overcurrent, overtemperature) and triggers shutdown sequences to prevent damage.

Core Functionality:

-

High-Voltage Handling: Designed to work with high-voltage power electronic devices (e.g., GTOs rated up to 4500V/3000A), ensuring reliable operation in harsh turbine environments.

-

Signal Conditioning: Filters and amplifies gate signals to ensure accurate device switching, minimizing losses and improving efficiency.

-

Fault Protection: Includes built-in protection circuits (e.g., overcurrent, overtemperature) to safeguard devices from abnormal operating conditions.

Platform Benefits (Mark V Series):

The DS200FHVAG1ABA leverages GE’s Mark V platform, which is renowned for:

-

Reliability: Industrial-grade components and a rugged design ensure 24/7 operation in turbine halls (e.g., high temperature, vibration).

-

Integration: Seamlessly connects with Mark V controllers (e.g., IS200 series) and drive systems, reducing setup time and effort.

-

Legacy Support: Maintains compatibility with existing turbine control architectures, critical for power plants and industrial facilities with legacy Mark V installations.

Technical Specifications

-

Model Number: DS200FHVAG1ABA

-

Manufacturer: GE (General Electric)

-

Product Type: High-Voltage Gate Interface Board

-

Series: Mark V

-

Functional Acronym: FHVA (High-Voltage Gate Interface Assembly)

-

Operating Temperature: -40°C to +85°C (-40°F to 185°F)

-

Storage Temperature: -40°C to +85°C (-40°F to 185°F) (inferred from industrial-grade standards)

-

Humidity: 5–95% non-condensing (inferred from industrial-grade standards)

-

Dimensions: 173 mm × 101 mm × 51 mm (6.81 in × 4.0 in × 2.0 in) (inferred from similar Mark V series products)

-

Weight: 0.5 kg (1.1 lbs) (inferred from similar Mark V series products)

-

Certifications: CE, UL (inferred from GE industrial product standards)

Core Features & Customer Value

1. Precise High-Voltage Gate Control:

The DS200FHVAG1ABA generates high-current pulses with rise/fall times <1 μs, ensuring accurate switching of high-power devices. This precision is critical for maintaining turbine speed and power output stability in gas/steam turbines.

2. Fault Protection:

Built-in overcurrent and overtemperature protection prevents device damage during abnormal operating conditions (e.g., short circuits, overloads). This protection extends the lifespan of expensive components, minimizing downtime and repair costs.

3. Rugged Industrial Design:

The board’s operating temperature range (-40°C to +85°C) and compact form factor make it suitable for harsh turbine hall environments. Its connectors and indicators are designed to resist vibration and dust, ensuring reliable operation.

4. Legacy System Compatibility:

As part of the Mark V series, the DS200FHVAG1ABA integrates with existing turbine control systems, reducing the need for costly upgrades. This compatibility is invaluable for facilities with legacy Mark V installations.

Typical Applications

The GE DS200FHVAG1ABA is widely used in turbine control systems for:

-

Gas Turbine Drives:

-

Controls GTO thyristors in gas turbine generators, regulating power output to the grid. For example, in a combined-cycle power plant, the board ensures that the gas turbine’s power output matches grid demand, maintaining stability.

-

-

Steam Turbine Drives:

-

Drives GTO thyristors in steam turbine systems, controlling the flow of steam to the turbine blades. This ensures efficient energy conversion from steam to mechanical power.

-

-

Industrial Motor Control:

-

Used in high-power motor drives (e.g., pumps, compressors) for industrial automation, providing precise speed and torque control.

-