Description

DS200GSNAG1A: Product Overview

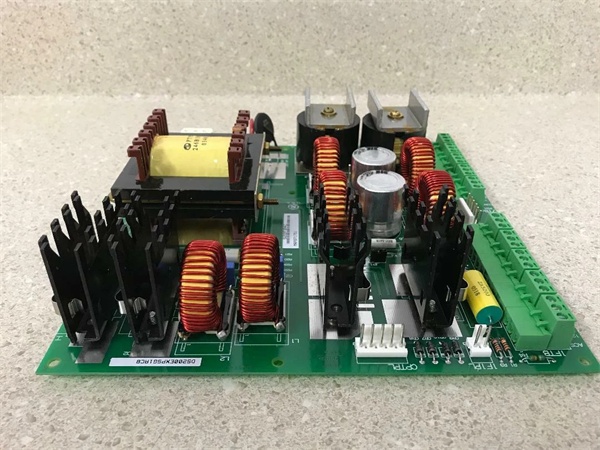

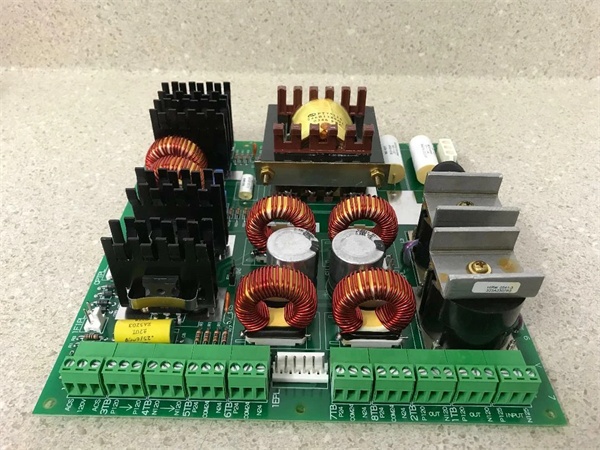

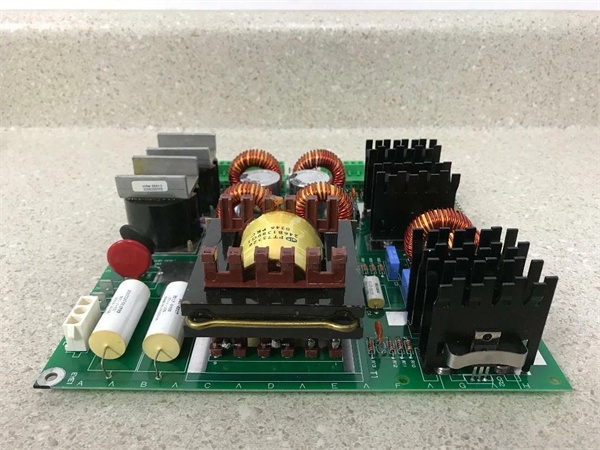

The GE DS200GSNAG1A is a specialized GTO snubber board designed for integration into GE’s Mark V series of turbine control systems. As a critical component of power electronic drive assemblies, it addresses a key challenge in high-power applications: managing voltage spikes and transients that occur during the switching of GTO thyristors. These spikes can damage sensitive components, leading to downtime and costly repairs. The DS200GSNAG1A mitigates this risk by absorbing and dissipating transient energy, ensuring stable and reliable operation of turbine drive systems.

Role in Automation Systems:

Positioned as a “protective interface” in Mark V drive systems, the DS200GSNAG1A performs two primary functions:

-

Transient Suppression: Reduces voltage spikes generated by GTO thyristors during switching, preventing damage to the thyristors themselves and other downstream components (e.g., capacitors, inductors).

-

System Stability: Maintains consistent voltage levels in the drive circuit, ensuring that turbine motors and generators operate within safe parameters. This stability is critical for applications like gas/steam turbines, where even minor voltage fluctuations can impact performance.

Core Functionality:

-

Snubber Circuit Design: The board incorporates snubber circuits (typically consisting of resistors, capacitors, and diodes) tailored to GTO thyristors. These circuits absorb transient energy and redirect it away from sensitive components.

-

Rugged Construction: Built with industrial-grade components and a normal PCB coating, the DS200GSNAG1A resists environmental factors like dust, moisture, and vibration—common in turbine hall environments.

-

Mark V Integration: Designed to seamlessly connect with Mark V series controllers (e.g., IS200 series) and drive systems, reducing setup time and ensuring compatibility with existing turbine control architectures.

Platform Benefits (Mark V Series):

The DS200GSNAG1A leverages GE’s Mark V platform, which is renowned for:

-

Reliability: Industrial-grade components and a rugged design ensure 24/7 operation in harsh turbine environments.

-

Legacy Support: As a “final product” in the Mark V series, it maintains compatibility with existing turbine control systems, critical for power plants and industrial facilities with legacy installations.

- Scalability: Can be integrated with additional Mark V components (e.g., I/O boards, controllers) to accommodate growing system demands.

Technical Specifications

-

Model Number: DS200GSNAG1A

-

Manufacturer: GE (General Electric)

-

Product Type: GTO Snubber Board

-

Series: Mark V

-

Functional Acronym: GSNA (GTO Snubber Assembly)

-

PCB Coating: Normal coating (protects against environmental contaminants)

-

Operating Temperature: -40°C to +85°C (-40°F to 185°F)

-

Storage Temperature: -40°C to +85°C (-40°F to 185°F) (inferred from industrial-grade standards)

-

Humidity: 5–95% non-condensing (inferred from industrial-grade standards)

-

Dimensions: 173 mm × 101 mm × 51 mm (6.81 in × 4.0 in × 2.0 in) (inferred from similar Mark V series products)

-

Weight: 0.5 kg (1.1 lbs) (inferred from similar Mark V series products)

-

Certifications: CE, UL (inferred from GE industrial product standards)

Core Features & Customer Value

1. Enhanced Component Protection:

The DS200GSNAG1A’s snubber circuits effectively suppress voltage spikes, reducing the risk of GTO thyristor damage. This protection extends the lifespan of expensive components, minimizing downtime and repair costs—critical for power plants where unplanned outages can result in significant financial losses.

2. Improved System Stability:

By maintaining consistent voltage levels, the board ensures that turbine drive systems operate smoothly. For example, in a gas turbine, stable voltage prevents fluctuations in power output, supporting grid stability and compliance with utility regulations.

3. Rugged Industrial Design:

The board’s operating temperature range (-40°C to +85°C) and normal PCB coating make it suitable for harsh turbine hall environments. Its compact form factor and DIN rail mounting option simplify installation in crowded control cabinets, reducing setup time and effort.

4. Legacy System Compatibility:

As part of the Mark V series, the DS200GSNAG1A integrates with existing turbine control systems, eliminating the need for costly upgrades. This compatibility is invaluable for facilities with legacy Mark V installations, allowing them to enhance system reliability without replacing entire architectures.

Typical Applications

The GE DS200GSNAG1A is widely used in turbine control systems for:

-

Gas Turbine Drives:

-

Protects GTO thyristors in gas turbine generators, regulating power output to the grid. For example, in a combined-cycle power plant, the board ensures that the gas turbine’s power output remains stable, even during load changes.

-

-

Steam Turbine Drives:

-

Mitigates voltage spikes in steam turbine systems, controlling the flow of steam to the turbine blades. This ensures efficient energy conversion from steam to mechanical power.

-

-

Industrial Motor Control:

-

Used in high-power motor drives (e.g., pumps, compressors) for industrial automation, providing reliable protection for GTO thyristors and ensuring smooth operation.

-