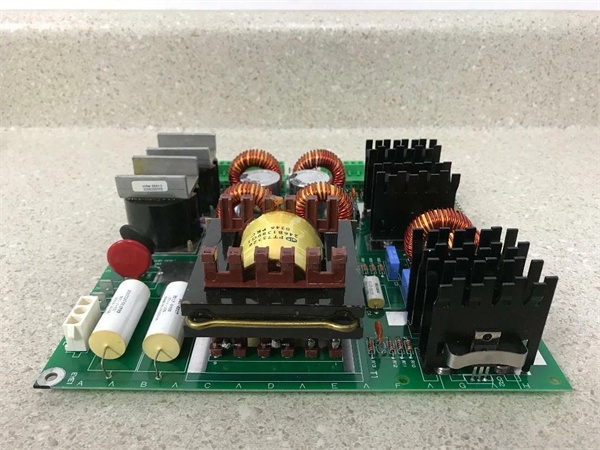

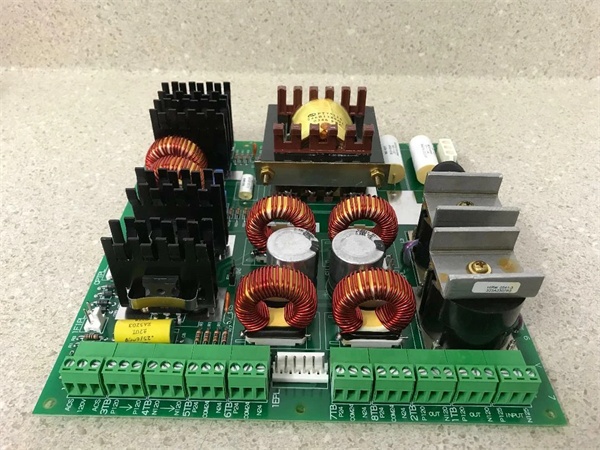

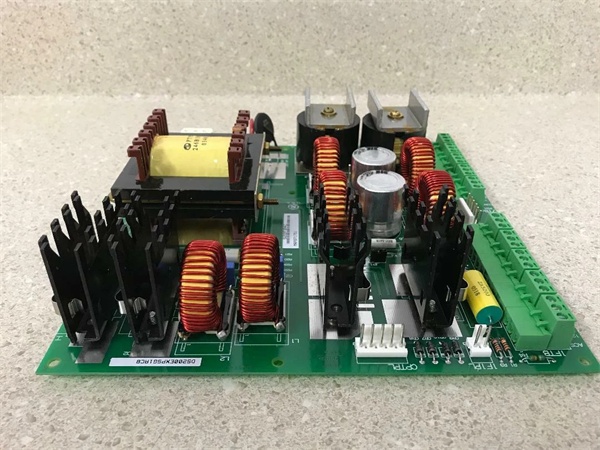

Description

-

Model Number: DS200RTBAG4A

-

Manufacturer: General Electric (GE)

-

Function: RST relay terminal – brings field contacts & excitation relays into Mark V rack

-

Relay Coils: 115 VAC 50/60 Hz (jumper-selectable 24 VDC or 125 VDC on later revs)

-

Termination: 190-position screw-block (95 per side)

-

Jumpers: 17 berg positions for coil voltage, pull-up, and filter selection

-

Isolation: 2 kV basic coil-to-logic; 500 V contact-to-contact

-

Connectors: 96-pin DIN 41612 to VME back-plane; screw terminals for field wires

-

Operating Temperature: –40 °C…+70 °C

-

Dimensions / Weight: 159 × 178 mm, 0.7 kg typical

-

Protection Degree: IP20 rack-mount

- Status: Factory discontinued – new & tested spares available

In the field the biggest headache is landing dozens of field contacts and power-excitation relays—oil-pressure switches, breaker status, and 115 VAC auxiliary contacts—without turning the turbine panel into a spaghetti bowl. The DS200RTBAG4A solves that by giving you 190 screw terminals on one plug-in card. Slide it into the Mark V rack, land the wires, snap the 96-pin connector, and you’re done. You’ll typically find it on 7EA or 9F peakers where every auxiliary relay in the skid has to report back to the Speedtronic. Core value: it collapses three DIN-rail relay blocks, pull-up resistors, and high-voltage isolators into one 0.7 kg card you can swap while the unit is on turning gear

.

The silk-screen is read from the component side; set 24 V on a 115 V coil and the relay pulls in weak, chatters, and burns out in a week. Match the jumper map in GEI-100161 before you power up

.

Over-tighten and the screw posts crack; under-tighten and vibration walks the wire out. Use a calibrated screwdriver and stop when the washer flattens—then tug-test every wire.

The front is open; wash-down or salt mist will corrode the screw posts and give you intermittent “contact bounce.” If the cabinet fan ingests salt, bag the card during maintenance or mount it behind a filtered door.

Factory stock is gone; new & tested spares are available but lead-time can be 6-8 weeks. Keep one on the shelf or you’ll discover the weakness when the only spare on-site is a cracked relay base

.

Internally the card is a passive relay matrix—no CPU, no firmware. Each coil hits a 2 kV isolator, a pull-up resistor, and a noise filter; the 96-pin connector carries all 190 contacts plus power to the DSP. Because it’s hardware you can hot-swap it: pull the old card, land the wires exactly where they came from, snap the connector in, and the turbine sees all relays again in under five minutes