Description

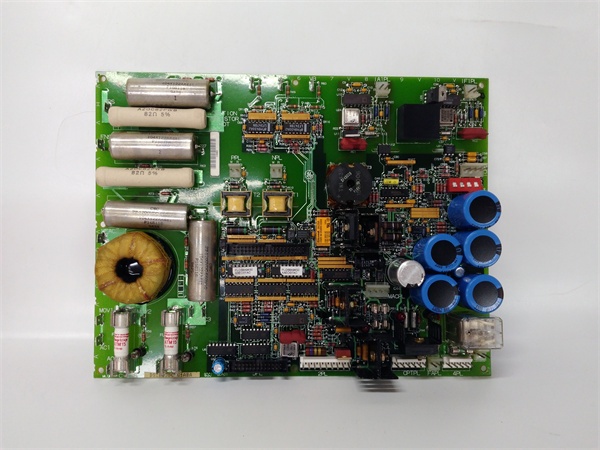

DS200IMCPG1CDB: Product Overview

The GE DS200IMCPG1CDB is a power supply interface board designed specifically for GE Speedtronic™ Mark V distributed control systems (DCS), the industry standard for gas, steam, and hydro turbine control in power generation. As part of the Mark V ecosystem, it acts as the “power bridge” between the DC2000 drive (used for turbine speed control) and downstream drive control boards (e.g., DS200SDCC). Its primary role is to distribute DC power to critical control components and protect against electrical faults (e.g., overvoltage), which is essential for maintaining turbine stability and preventing unplanned downtime.

Engineered for the demanding conditions of turbine halls, the DS200IMCPG1CDB features a robust PCB layout and secure connector interfaces to withstand continuous DC power transmission. Its legacy compatibility makes it ideal for retrofitting aging Mark V systems—common in power plants operating turbines for 20+ years—where replacing the entire control architecture is cost-prohibitive. Whether used in 7EA gas turbines or 9F steam turbines, the DS200IMCPG1CDB ensures stable power delivery, directly extending the operational life of critical turbine control systems.

Role in Automation Systems

Positioned as a “power hub” in Mark V architectures, the DS200IMCPG1CDB performs two primary functions:

-

Power Distribution: Routes DC power from the DC2000 drive to downstream drive control boards (e.g., DS200SDCC), ensuring each component receives the correct voltage and current. This is critical for maintaining turbine speed and load control.

-

Fault Protection: Integrates 8 onboard fuses to protect sensitive control electronics from overvoltage transients (e.g., from the DC2000 drive or external power sources). If a fault occurs (e.g., overvoltage), the corresponding fuse blows, isolating the affected component and preventing damage to the entire system.

Its core value lies in stabilizing power supply—a critical requirement for turbine control, where even minor voltage fluctuations can lead to process instability (e.g., turbine speed variations) or equipment damage (e.g., excitation system failure).

Core Functionality

-

DC Power Connection: The DS200IMCPG1CDB is designed to connect the DC2000 drive to downstream drive control boards via secure connectors (e.g., 1PL connector). This ensures that the drive control boards receive consistent DC power for reliable operation.

-

Overvoltage Protection: The 8 onboard fuses provide localized protection for critical components (e.g., microprocessors, memory) against overvoltage transients. This is essential for maintaining the integrity of the turbine control system, as overvoltage can cause permanent damage to sensitive electronics.

-

Legacy Compatibility: The DS200IMCPG1CDB is fully compatible with existing Mark V components (e.g., DC2000 drives, DS200SDCC drive control boards), reducing the cost of system upgrades. This makes it an ideal choice for power plants with aging Mark V systems, where replacing the entire control architecture is not feasible.

-

Easy Maintenance: The board’s modular design allows for quick replacement during maintenance, reducing downtime. The onboard fuses are easily accessible, allowing technicians to replace them without removing the entire board from the rack.

GE DS200SDCIG1A

Technical Specifications

-

Model Number: DS200IMCPG1CDB (Variant of Mark V Series)

-

Manufacturer: GE (General Electric)

-

Product Type: Power Supply Interface Board

-

Series: Mark V (Gas/Steam Turbine Control)

-

Form Factor: 6U Eurocard (160 mm × 233 mm)

-

Bus Standard: Proprietary Mark V bus (compatible with Mark V Series controllers)

-

Input Voltage: 24 V DC (nominal, from Mark V AC2000I backplane)

-

Output Voltage: +5 V DC (2 ports, 5A max each), +24 V DC (1 port, 5A max)

-

Protection: 8 onboard fuses (overvoltage protection, 250V AC/125V DC rated)

-

Operating Temperature: 0°C to +55°C (32°F to 131°F)

-

Storage Temperature: -40°C to +85°C (-40°F to 185°F)

-

Humidity: 5–95% non-condensing

-

Weight: ~0.45 kg (1 lb)

-

Certifications: CE, UL (inferred from GE industrial product standards)

Core Features & Customer Value

1. Reliable Power Distribution:

The DS200IMCPG1CDB’s robust design ensures stable DC power delivery to downstream drive control boards, even in harsh industrial environments. For example, in a power plant, the board can handle voltage fluctuations from the DC2000 drive and still provide consistent power to the turbine controller, preventing unexpected shutdowns.

2. Fault Protection:

The 8 onboard fuses provide critical overvoltage protection, reducing the risk of damage to sensitive control electronics. This is invaluable for power plants, where unplanned downtime can result in significant financial losses.

3. Legacy Compatibility:

Designed to work with existing Mark V components, the DS200IMCPG1CDB eliminates the need for costly system upgrades. This makes it an ideal choice for power plants with aging Mark V systems, where replacing the entire control architecture is not feasible.

4. Easy Maintenance:

The board’s modular design and accessible fuses allow for quick replacement during maintenance, reducing downtime. This is critical for power plants, where every minute of downtime can impact power output and revenue.

GE DS200SDCIG1A

Typical Applications

The GE DS200IMCPG1CDB is widely used in industrial automation systems for:

-

Power Generation:

-

Provides power distribution and protection for gas/steam turbine control systems, ensuring stable power output.

-

-

Industrial Drives:

-

Used in industrial motor drives (e.g., conveyor belts, pumps) to connect DC drives to downstream control boards, ensuring reliable power transmission.

-

-

Retrofit Projects:

-

Ideal for retrofitting aging Mark V systems, where replacing the entire control architecture is cost-prohibitive. The board’s legacy compatibility allows for easy integration with existing components.

-