Description

Detailed Parameter Table

**

| Parameter Name | Parameter Value |

| Product model | GE DS200IQXSG1A |

| Manufacturer | General Electric (GE) Industrial Automation |

| Product category | Intelligent Quadrature Excitation Signal Generator (Precision Control for Drive Systems) |

| Series | GE Drive Control Series (compatible with Mark V, Mark VIe, and some EX2000 variants) |

| Power Requirements | +12V DC (3A typical, 4A peak); -12V DC (1.5A typical) |

| Signal Output Channels | 4 independent channels for quadrature (IQ) signals; 2 additional channels for auxiliary control signals |

| Frequency Range | 0 Hz – 500 kHz (adjustable in 0.1 Hz increments); Accuracy: ±0.01% of set frequency |

| Phase Accuracy | ±0.1° (over full frequency range); Phase adjustability: -180° to +180° in 0.1° steps |

| Amplitude Range | 0 Vpp – 10 Vpp (adjustable in 0.01 Vpp increments); Amplitude accuracy: ±0.5% of set value |

| Signal Waveform | Sine, Cosine (for IQ pairs); Square, Triangle (for auxiliary channels); Total Harmonic Distortion (THD) < 0.1% (sine wave) |

| Digital Interface | RS-485 (Modbus RTU protocol); Supports up to 32 devices on a single bus; Baud rate: 9600 – 115200 bps |

| Analog Inputs | 2 channels for external feedback (0 V – 5 V DC); Used for closed – loop control and calibration |

| Operating Temperature Range | -25°C to +65°C; Humidity tolerance: 5% – 95% non – condensing |

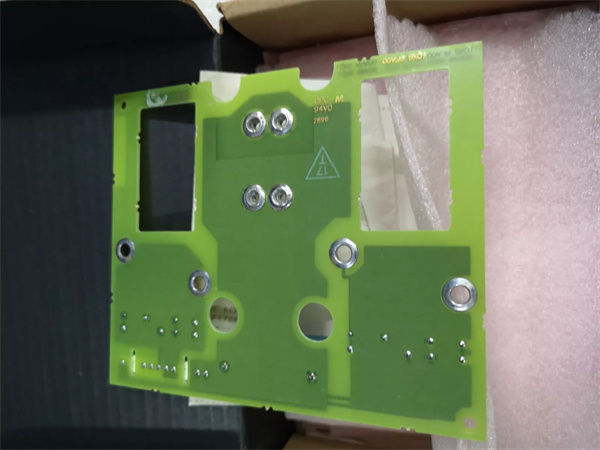

| Physical Dimensions (H×W×D) | 14.5 cm × 16.2 cm × 3.8 cm; Weight: 280g |

| Mounting Method | DIN-rail mounting (compatible with standard 35mm DIN rails); Can also be panel – mounted with optional brackets |

| Connector Type | Screw – type terminals for power and analog signals; DB9 connector for RS-485 interface |

| Protection Features | Over – voltage protection (up to 15V DC on power inputs); Reverse polarity protection; Over – temperature shutdown (70°C) |

| Certifications | CE, UL 508C, IEC 61010 – 1; Compliant with relevant electromagnetic compatibility (EMC) standards |

| Compatibility | GE drive control systems (Mark V, Mark VIe); Third – party drives with Modbus RTU interface (with proper configuration) |

| Diagnostic Indicators | 4x channel status LEDs (green = signal active); 1x power LED (red = power on); 1x fault LED (amber = over – temperature, communication error, etc.) |

| Country of Origin | United States; RoHS – compliant (lead – free components) |

| Technical Manual | GEH – 6130 (provides detailed operation, calibration, and troubleshooting guidelines) |

GE DS200IQXSG1A

Product Introduction

The GE DS200IQXSG1A is an intelligent quadrature excitation signal generator meticulously engineered by General Electric for high – precision drive control systems. As a key component in power electronics and motion control applications, it plays a crucial role in providing accurate and stable excitation signals.

This device addresses the need for precise control of motors, especially in applications where smooth operation, high – torque output, and accurate speed regulation are essential. By generating quadrature (IQ) signals, the GE DS200IQXSG1A enables advanced motor control algorithms, such as vector control, which significantly improves the performance of AC induction motors, synchronous motors, and brushless DC motors.

Designed for both new installations and retrofits, the GE DS200IQXSG1A can be easily integrated into existing GE drive control systems, like the Mark V and Mark VIe series. Its compact size and flexible mounting options make it suitable for a wide range of industrial environments, from factory floors to power generation facilities.

Core Advantages and Technical Highlights

Precise Signal Generation

The GE DS200IQXSG1A offers an extremely wide frequency range from 0 Hz to 500 kHz with an impressive accuracy of ±0.01% of the set frequency. This high – level precision ensures that motors operate at their optimal speed, reducing energy consumption and mechanical wear. For example, in a high – speed spindle motor used in a precision machining center, the accurate frequency control provided by the GE DS200IQXSG1A enables the spindle to rotate at a precise speed, resulting in better surface finish and dimensional accuracy of the machined parts.

The phase accuracy of ±0.1° over the full frequency range is another remarkable feature. In applications that require coordinated movement of multiple motors, such as in robotic arms or multi – axis CNC machines, the precise phase control ensures smooth and synchronized motion. The ability to adjust the phase from – 180° to +180° in 0.1° steps gives engineers the flexibility to fine – tune the motor control system for optimal performance.

Flexible Signal Output

With 4 independent channels for generating quadrature signals and 2 additional channels for auxiliary control signals, the GE DS200IQXSG1A provides great versatility. The signal waveforms include sine, cosine for IQ pairs, as well as square and triangle for auxiliary channels. The low total harmonic distortion (THD) of less than 0.1% for sine waves ensures clean and pure signals, minimizing interference with other components in the drive system. This is particularly important in sensitive applications, such as medical equipment or aerospace systems, where signal integrity is critical.

Digital Connectivity and Control

The RS – 485 interface with Modbus RTU protocol allows for easy integration into digital control networks. It can support up to 32 devices on a single bus, enabling centralized control and monitoring. The wide range of baud rates (9600 – 115200 bps) provides flexibility in network design, allowing for high – speed data transfer in large – scale systems or lower – speed, more reliable communication in noisy industrial environments. For instance, in a large – scale factory automation system, the GE DS200IQXSG1A can be easily connected to a programmable logic controller (PLC) via the RS – 485 interface, allowing the PLC to remotely control the signal generation parameters and monitor the device’s status.

Robust Environmental Performance

The GE DS200IQXSG1A is designed to operate in a wide temperature range of – 25°C to +65°C and can withstand humidity levels from 5% to 95% non – condensing. This makes it suitable for use in harsh industrial environments, such as cold storage facilities, outdoor power generation stations, or humid manufacturing plants. The over – temperature shutdown at 70°C protects the device from damage during extreme heat conditions, ensuring long – term reliability.

Typical Application Scenarios

Precision Machining

In a high – end CNC milling machine, the GE DS200IQXSG1A is used to control the spindle motor and the feed motors. The precise frequency and phase control of the quadrature signals enable the spindle to rotate at a consistent speed, while the feed motors move the workpiece with high accuracy. This results in the production of complex and highly accurate parts, such as those used in aerospace engine manufacturing. The device’s ability to generate clean signals also reduces electrical interference, which could otherwise affect the performance of other sensitive components in the CNC machine.

Industrial Robotics

In a robotic assembly line, the GE DS200IQXSG1A is integrated into the robot’s drive control system. It provides the necessary quadrature signals to control the motors of each joint, ensuring smooth and coordinated movement. The precise phase control allows the robot to perform complex tasks, such as picking and placing small components with high accuracy. The digital connectivity of the GE DS200IQXSG1A enables the robot controller to easily adjust the signal parameters in real – time, adapting to different production requirements.

Power Generation

In a wind turbine control system, the GE DS200IQXSG1A is used to control the pitch motors of the turbine blades. By providing accurate excitation signals, it ensures that the blades are adjusted to the optimal angle based on wind speed and direction. This maximizes the energy capture efficiency of the wind turbine. The device’s wide operating temperature range makes it suitable for use in harsh outdoor environments, where temperature fluctuations can be significant.

GE DS200IQXSG1A

Related Model Recommendations

GE DS200IQXSG0A: Predecessor to the GE DS200IQXSG1A with a narrower frequency range (0 Hz – 200 kHz) and less precise phase control (±0.5°). Suitable for less demanding applications where cost is a major consideration.

GE Mark V Controller: A drive control system that pairs perfectly with the GE DS200IQXSG1A. It provides overall control and coordination for the drive system, allowing for seamless integration of the signal generator.

GE Mark VIe Controller: An advanced drive control system with enhanced communication capabilities and processing power. Compatible with the GE DS200IQXSG1A, it is suitable for more complex and high – performance drive applications.

GE DS200TERMG5: Terminal block kit for the GE DS200IQXSG1A. It includes shielded terminal blocks and wire markers, making wiring installation more organized and secure.

GE HMM – 002: Handheld monitor for the GE DS200IQXSG1A. Allows on – site testing and monitoring of signal parameters without powering down the entire drive system.

GE 5SDA05H4000 IGBT Module: Can be used in conjunction with the GE DS200IQXSG1A in motor drive applications. The signal generator provides the excitation signals, while the IGBT module controls the power flow to the motor.

GE IC698CPE040 – FJGE: Mark VIe CPU that can be used to monitor and control the GE DS200IQXSG1A via the RS – 485 interface. It enables remote configuration and troubleshooting of the signal generator.

GE DS200IQXSG1A – ENC: Optional enclosure for the GE DS200IQXSG1A that provides additional protection against dust, water, and electromagnetic interference. Suitable for use in harsh industrial environments.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing the GE DS200IQXSG1A, carefully review the technical manual (GEH – 6130) to ensure compatibility with the existing drive system. Power off the drive system and follow proper lockout/tagout procedures to avoid electrical shock. Required tools include a DIN – rail cutter (if mounting on a DIN – rail), a torque screwdriver (0.3 – 0.6 N·m for terminal screws), an anti – static wristband, and a multimeter for initial testing.

When mounting the device, ensure that the mounting surface is flat and clean. If using the DIN – rail mounting option, slide the GE DS200IQXSG1A onto the standard 35mm DIN – rail and secure it with the provided screws. For panel – mounting, use the optional brackets and drill appropriate holes in the panel. Connect the power wires to the screw – type terminals, ensuring correct polarity. The +12V DC and – 12V DC power inputs should be connected to a reliable power source that can supply the required current. Connect the analog input wires (if applicable) and the RS – 485 communication wires to the appropriate terminals.

Commissioning & Maintenance Suggestions

During commissioning, power on the drive system and check the status LEDs on the GE DS200IQXSG1A. The power LED should be red, indicating that power is supplied correctly. The channel status LEDs should be green if signals are being generated. Use the GE HMM – 002 handheld monitor or a compatible software tool (connected via the RS – 485 interface) to configure the signal parameters, such as frequency, phase, and amplitude. Start with low – frequency and low – amplitude settings and gradually increase them while monitoring the motor’s performance.

For daily maintenance, regularly check the status LEDs to ensure that no fault LEDs are illuminated. Inspect the connectors for any signs of 松动 (loosening) or corrosion. If corrosion is detected, clean the connectors with isopropyl alcohol and a soft brush. Every 3 months, use the multimeter to check the power supply voltages to ensure they are within the specified range. Once a year, perform a full calibration of the GE DS200IQXSG1A using the procedures outlined in the GEH – 6130 manual. This involves adjusting the signal parameters to known reference values and verifying the accuracy of the output signals.

If a fault occurs, refer to the GEH – 6130 manual for troubleshooting guidelines. The fault LED may indicate over – temperature, communication errors, or other issues. Use the HMM – 002 to check for error codes and isolate the problem. If the problem cannot be resolved through troubleshooting, contact GE technical support or replace the GE DS200IQXSG1A with a new or reconditioned unit.

Service and Guarantee Commitment

The GE DS200IQXSG1A comes with a 48 – month manufacturer’s warranty, covering defects in materials and workmanship under normal industrial use. If the device fails within the warranty period, GE provides a prompt replacement service. For priority customers, such as large – scale industrial plants or power generation companies, GE can deliver a pre – calibrated replacement within 48 hours, minimizing downtime.

GE offers 24/7 global technical support for the GE DS200IQXSG1A. Customers can access a team of experienced engineers via phone or email for assistance with installation, commissioning, troubleshooting, and maintenance. GE also provides free software updates and access to the latest version of the GEH – 6130 manual for 2 years after purchase. For enhanced reliability, GE’s Drive Care Program includes annual on – site inspections and calibration of the GE DS200IQXSG1A, ensuring that the device continues to operate at peak performance.