Description

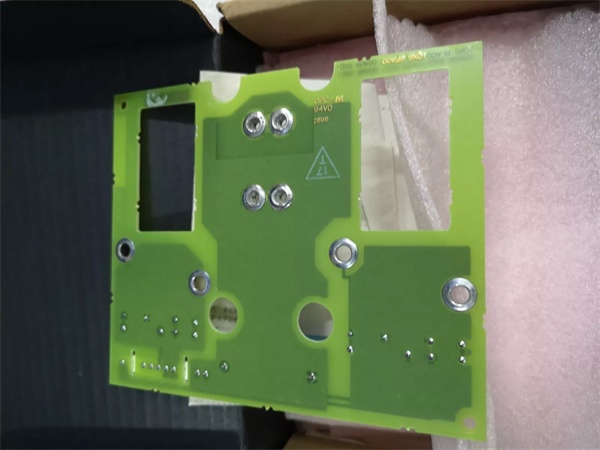

DS200IQXSG1A: Product Overview

The GE DS200IQXSG1A is a specialized analog I/O board designed for integration into GE’s Mark V series of gas turbine control systems. As a critical component of the Mark V ecosystem, it enables precise signal conditioning and conversion for a wide range of analog signals, ensuring reliable operation of turbine control and monitoring functions.

Role in Automation Systems:

Positioned as a “signal interface” between field devices (e.g., LVDT position sensors, thermocouples, pressure transmitters) and the Mark V controller, the DS200IQXSG1A performs two primary functions:

-

Signal Conditioning: Filters, amplifies, and scales raw analog signals from field devices to ensure accuracy and consistency.

-

Signal Conversion: Converts conditioned analog signals into digital data for processing by the Mark V controller, enabling real-time control and monitoring.

Core Functionality:

-

Signal Support: Handles LVDT inputs (for position sensing), thermocouple inputs (for temperature measurement), 4–20 mA current loops (for pressure/flow sensors), and ±10 V DC voltage inputs (for general-purpose analog signals).

-

Hardware Configuration: Uses jumpers (e.g., J1–J8) to select signal types, configure output ranges (e.g., 4–20 mA vs. 0–20 mA), and enable test modes (e.g., RS232 port for card testing).

-

Communication: Transmits processed signals to the Mark V controller via the 3PL data bus and exchanges generator/line signals with other I/O boards (e.g., TCQC) via the JE connector.

Platform Benefits (Mark V Series):

The DS200IQXSG1A leverages GE’s Mark V platform, which is renowned for:

-

Reliability: Industrial-grade components and a rugged design ensure 24/7 operation in harsh turbine hall environments.

-

Scalability: Supports expansion with additional I/O boards to accommodate growing system demands (e.g., adding more sensors or actuators).

-

Integration: Seamlessly integrates with Mark V controllers and other I/O cores (R1, R2, R3), reducing setup time and effort.

GE DS200IQXSG1A

Technical Specifications

-

Model Number: DS200IQXSG1A

-

Manufacturer: GE (General Electric)

-

Product Type: Analog I/O Board

-

Series: Mark V

-

Signal Inputs:

-

LVDT (Linear Variable Differential Transformer)

-

Thermocouple (Type J, K, T, etc.)

-

4–20 mA current loop

-

±10 V DC voltage

-

-

Signal Outputs:

-

4–20 mA current loop (configurable via jumpers)

-

±10 V DC voltage

-

-

Connectors:

-

3PL (data bus to STCA, TCQA, TCQE boards)

-

JE (generator/line signals to TCQC board)

-

JB (4–20 mA I/O to TBQC terminal board)

-

-

Hardware Jumpers:

-

J1/J2: Select milliamp output circuit

-

J5/J6: Configure milliamp output range (20 mA or 200 mA)

-

J7: Enable RS232 port for card testing

-

J8: Start oscillator for signal generation

-

-

Operating Temperature: -20°C to +60°C (-4°F to 140°F)

-

Storage Temperature: -40°C to +85°C (-40°F to 185°F)

-

Humidity: 5–95% non-condensing

-

Dimensions: 173 mm × 112 mm × 13 mm (6.81 in × 4.41 in × 0.51 in)

-

Weight: 0.12 kg (0.26 lbs)

-

Certifications: CE, UL (inferred from GE industrial product standards)

Core Features & Customer Value

1. Flexible Signal Handling:

The DS200IQXSG1A supports a wide range of analog signals, making it suitable for diverse turbine control applications. For example, LVDT inputs can be used to monitor turbine blade position, while thermocouple inputs measure exhaust gas temperature—providing critical data for optimizing turbine performance.

2. Easy Configuration:

Hardware jumpers allow engineers to customize the board’s functionality without software changes. For instance, configuring the milliamp output range (20 mA vs. 200 mA) via J5/J6 enables the board to interface with different types of actuators (e.g., small valves vs. large pumps), reducing the need for additional hardware.

3. Reliable Communication:

The 3PL data bus and JE connector ensure seamless communication with other Mark V components, minimizing latency and ensuring real-time signal transmission. This reliability is critical for turbine control, where delayed signals could lead to equipment damage or downtime.

4. Rugged Design:

The board’s operating temperature range (-20°C to +60°C) and compact form factor make it suitable for harsh turbine hall environments. Its DIN rail mounting option simplifies installation in crowded control cabinets, reducing setup time and effort.

GE DS200IQXSG1A

Typical Applications

The GE DS200IQXSG1A is widely used in gas turbine control systems for:

-

Turbine Blade Position Monitoring:

-

Uses LVDT inputs to measure the position of turbine blades, enabling the Mark V controller to adjust blade angles for optimal efficiency.

-

-

Exhaust Gas Temperature Measurement:

-

Uses thermocouple inputs to monitor exhaust gas temperature, helping to prevent overheating and optimize combustion.

-

-

Pressure/Flow Control:

-

Uses 4–20 mA inputs to measure pressure and flow rates in fuel lines, enabling the controller to adjust fuel flow for consistent turbine output.

-

-

Generator/Line Signal Exchange:

-

Uses the JE connector to exchange generator and line signals with other I/O boards (e.g., TCQC), supporting grid synchronization and power output control.

-