Description

Detailed Parameter Table

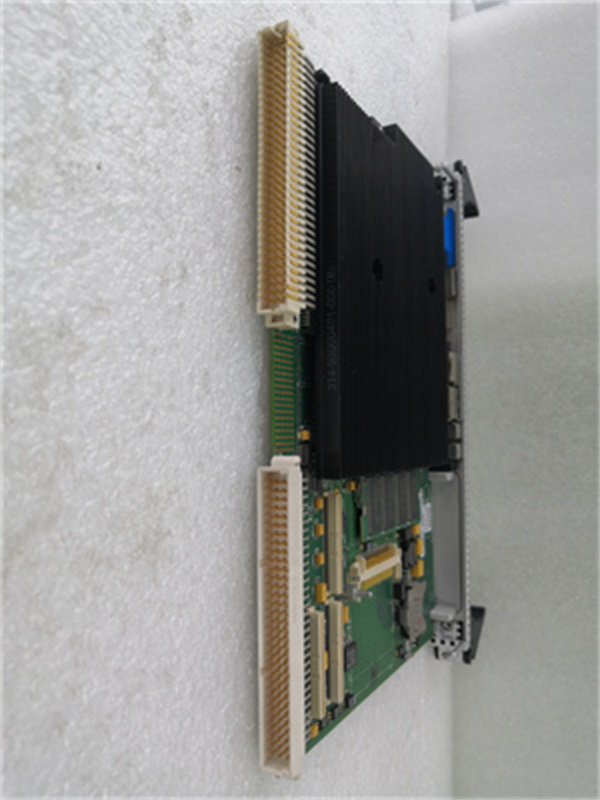

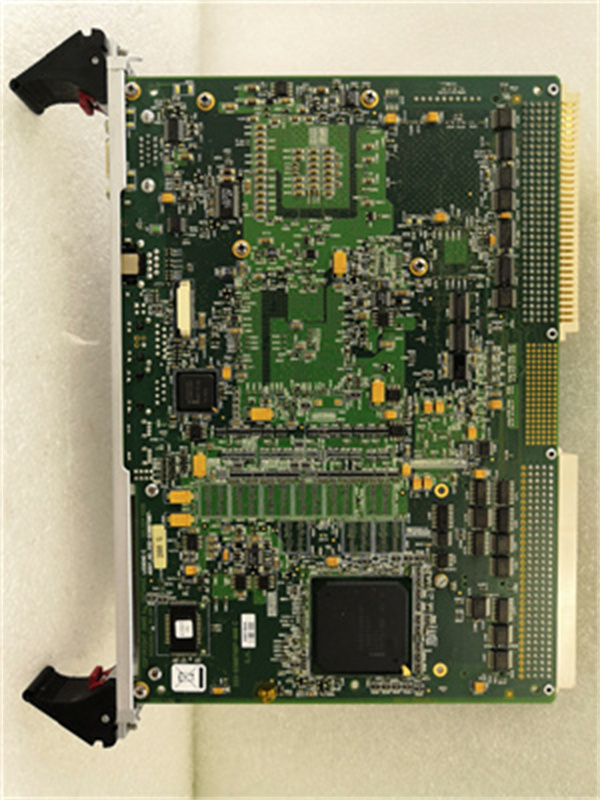

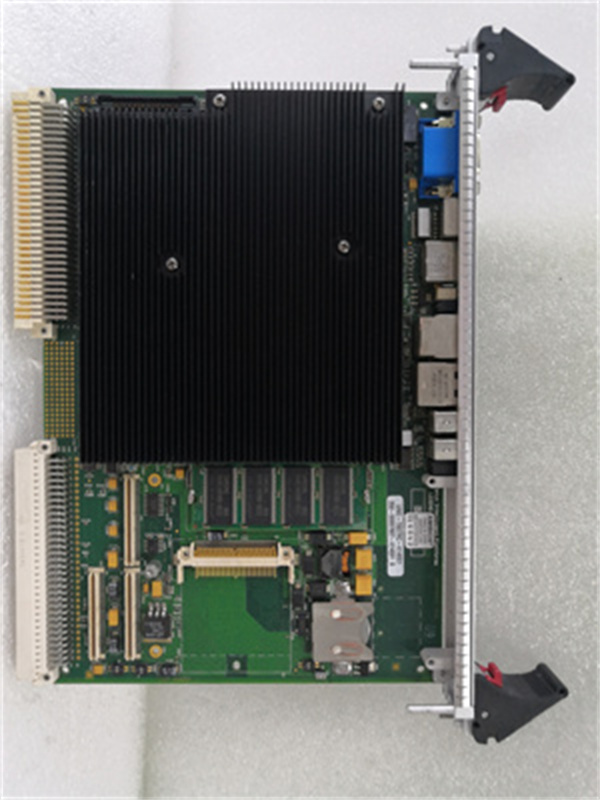

| Parameter Name | Parameter Value |

| Product model | GE DS200ISCAG1A |

| Manufacturer | General Electric (GE) Industrial Automation |

| Product category | Intelligent Signal Conditioning Module (Mark VIe/EX2000 Series) |

| Input Channels | 8 universal analog input channels (configurable per channel) |

| Input Signal Types | Voltage (±5V, ±10V, 0-5V, 0-10V); Current (4-20mA, 0-20mA); Thermocouple (J, K, T, E) |

| Output Signal | 16-bit digital output (to Mark VIe CPU via backplane); 4-20mA isolated analog retransmission (optional) |

| Isolation Rating | 2.5kVrms channel-to-channel; 5kVrms channel-to-ground |

| Accuracy | ±0.05% of full scale (voltage/current); ±0.1°C (thermocouple) |

| Sampling Rate | 100Hz per channel (simultaneous sampling) |

| Interface Type | 1x 50-pin backplane connector (Mark VIe); 2x 24-pin terminal blocks (field wiring) |

| Power Requirements | 24V DC (from Mark VIe backplane); 0.5A typical, 0.7A maximum |

| Physical Dimensions (H×W×D) | 125mm × 100mm × 30mm; Weight: 180g |

| Operating Temperature Range | -25°C to +70°C (ambient); -40°C to +85°C (storage) |

| Certifications | CE, UL 508C, IEC 61010-1, ATEX Zone 2, IEC 61508 (SIL 2) |

GE DS200FCGDH1B

Product introduction

GE DS200ISCAG1A is an advanced intelligent signal conditioning module designed for GE’s Mark VIe and EX2000 control systems, serving as a critical interface between field sensors and the central processing unit. Its primary function is to receive, isolate, amplify, and linearize raw analog signals from diverse industrial sensors—including pressure transducers, thermocouples, and flow meters—before transmitting precise digital data to the control system.

In complex automation environments, GE DS200ISCAG1A solves the common challenge of signal integrity: industrial sensors often generate weak or noisy signals that can be corrupted by electromagnetic interference (EMI) from motors, transformers, or high-voltage equipment. By incorporating 2.5kVrms channel isolation and precision signal conditioning, GE DS200ISCAG1A ensures that the Mark VIe CPU receives accurate data, enabling reliable control decisions in applications like turbine monitoring, process temperature regulation, and pressure control loops.

What distinguishes GE DS200ISCAG1A from basic conditioning modules is its channel-level configurability—each of the 8 inputs can be independently set to handle different signal types without hardware modifications. This flexibility makes GE DS200ISCAG1A ideal for mixed-signal environments, such as chemical processing plants or power generation facilities, where a single module must interface with multiple sensor technologies.

Core advantages and technical highlights

Universal Input Flexibility: Each of GE DS200ISCAG1A’s 8 channels can be individually configured via software to accept voltage, current, or thermocouple signals—eliminating the need for separate modules for different sensor types. In a combined-cycle power plant, for example, one channel can process a 4-20mA pressure signal from a steam line, while another handles a K-type thermocouple reading from a turbine exhaust, and a third accepts a ±10V signal from a flow meter. This versatility reduces cabinet space requirements by up to 50% compared to using single-type conditioning modules.

High-Isolation Protection: GE DS200ISCAG1A features 2.5kVrms channel-to-channel isolation and 5kVrms channel-to-ground isolation, a critical advantage in high-voltage industrial environments. This isolation prevents ground loops and protects sensitive Mark VIe components from voltage spikes—common in applications with variable frequency drives or arc furnaces. In a steel mill, where EMI levels are extreme, GE DS200ISCAG1A’s isolation ensures temperature readings from the rolling mill remain accurate within ±0.1°C, preventing quality defects in finished steel products.

Precision Measurement with Diagnostics: With ±0.05% full-scale accuracy and 100Hz simultaneous sampling, GE DS200ISCAG1A delivers reliable data for critical control loops. The module also includes built-in diagnostics: it continuously monitors for open thermocouple wires, shorted current loops, and out-of-range signals, flagging issues via the Mark VIe system before they cause process disruptions. In a refinery’s catalytic cracker unit, this early warning capability allows technicians to replace a failing pressure sensor before it leads to an unplanned shutdown—saving an estimated $200,000 in lost production.

Typical application scenarios

GE DS200ISCAG1A is widely used in gas turbine control systems, where precise measurement of multiple parameters is essential for safe, efficient operation. In a 600MW combined-cycle plant, GE DS200ISCAG1A is installed in the Mark VIe cabinet, processing 8 critical signals: 3 thermocouple readings (turbine inlet, exhaust, bearing temperature), 2 pressure transducers (combustion chamber, lube oil), 2 flow meters (fuel gas, cooling water), and 1 vibration sensor (converted to 4-20mA).

The module’s isolation protects these signals from EMI generated by the turbine’s generator, ensuring the control system receives accurate data even during high-load operation. During startup, GE DS200ISCAG1A’s diagnostics detect an open circuit in the exhaust thermocouple, triggering an alarm in the control room. Technicians replace the sensor during the startup sequence, avoiding a potential turbine overheat event that could cause $500,000 in damage.

In a chemical processing plant, GE DS200ISCAG1A handles mixed signals from a reactor vessel: pH sensors (4-20mA), jacket temperature (T-type thermocouple), and pressure transducers (0-10V). Its software-configurable channels allow quick reconfiguration when the reactor is repurposed for a new product, reducing changeover time by 8 hours compared to fixed-input modules.

Related model recommendations

GE IS420YDIAS1B: Mark VIe digital input module that works with GE DS200ISCAG1A to provide comprehensive I/O coverage; handles discrete signals from switches and relays.

GE DS200DSPCH1A: Digital signal processing module that receives conditioned data from GE DS200ISCAG1A; performs advanced filtering for time-critical control loops.

GE DS200EXPSG1A: Power supply module that provides stable 24V DC to GE DS200ISCAG1A and other Mark VIe components; ensures consistent performance during voltage fluctuations.

GE IC698CPE040-FJGE: Mark VIe CPU that processes data from GE DS200ISCAG1A; executes control logic for turbine, generator, and process systems.

GE DS200TERMG6: Terminal block kit designed for GE DS200ISCAG1A; includes color-coded terminals and wire markers for organized field wiring.

GE DS200ISCBG1A: 16-channel variant of GE DS200ISCAG1A; ideal for large-scale systems requiring more input channels, such as refinery process units.

GE Proficy Machine Edition v10.0: Configuration software for GE DS200ISCAG1A; allows channel parameter setup, diagnostic monitoring, and calibration.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing GE DS200ISCAG1A, verify compatibility with the Mark VIe backplane (e.g., GE IC698CMX016) and ensure the operating environment is within -25°C to +70°C. Required tools include a torque screwdriver (0.4 N·m for backplane mounting), wire strippers (22-14 AWG), ESD-safe gloves, and a laptop with Proficy Machine Edition. Safety precautions: Power off the Mark VIe system and apply lockout/tagout. Align GE DS200ISCAG1A with the backplane slot guides and press firmly until it engages—do not force the module. Connect field wiring to terminal blocks, ensuring proper shielding (grounded at one end) to minimize EMI.

Maintenance suggestions: For daily operation, monitor GE DS200ISCAG1A via Proficy Machine Edition to check for diagnostic alerts (open circuits, out-of-range signals). Every 6 months, verify calibration using a precision signal generator: inject known values (e.g., 12mA for a 4-20mA channel) and confirm readings are within ±0.05% of full scale. Inspect terminal blocks for corrosion or loose connections, retorquing to 0.5-0.8 N·m as needed. If a channel fails, first test the field sensor and wiring; if the issue persists, use the module’s built-in self-test function to isolate the fault. Replace GE DS200ISCAG1A with a GE-approved spare only if self-tests confirm hardware failure—third-party modules may compromise isolation ratings.

Service and guarantee commitment

GE DS200ISCAG1A comes with a 48-month manufacturer’s warranty from GE, covering defects in materials, workmanship, and performance under normal industrial use (per IEC 61010-1 and SIL 2 standards). If GE DS200ISCAG1A fails within the warranty period, GE provides a “rapid swap” service—pre-calibrated replacement modules are shipped within 48 hours for priority customers, minimizing downtime.

GE offers 24/7 global technical support for GE DS200ISCAG1A, with specialists available to assist with configuration, calibration, and troubleshooting via phone or email. Customers receive free access to Proficy Machine Edition software updates for 2 years post-purchase, ensuring compatibility with the latest Mark VIe firmware. For enhanced reliability, GE’s Mark VIe Care Program includes annual on-site calibration verification of GE DS200ISCAG1A, ensuring long-term measurement accuracy in critical applications.