Description

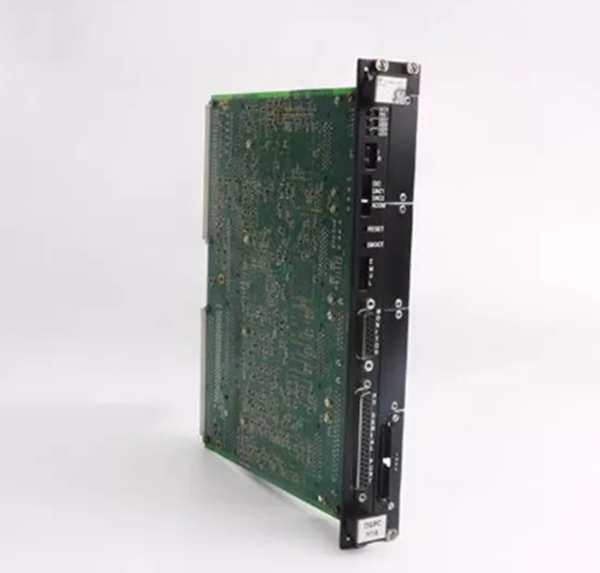

Professional Product Description: GE DS200KLDBG1A Display Keypad Board

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | GE DS200KLDBG1A |

| Manufacturer | General Electric (GE) |

| Product category | Display Keypad Board (Mark V Series) |

| Power requirements | +5V DC, 6A |

| Power supply voltage | 28V DC (Voltage range: 18 – 32V DC) |

| Number of input channels | 24 |

| Number of relay channels | 12 |

| Trip solenoid rating | 125V DC |

| Operating temperature range | -40°C to 70°C |

| PCB coating | Normal coating |

| Revision quantity | Multiple revisions available |

| Series | GE Mark V |

| Product type | Key/LED/Display Board |

| Product abbreviation | KLDB |

GE DS200DSPCH1A

Product introduction

The GE DS200KLDBG1A is a crucial display keypad board engineered by General Electric as part of the esteemed Mark V series. This series has been a cornerstone in industrial control systems, known for its reliability and high – performance capabilities. The DS200KLDBG1A board serves as a vital interface between operators and the overall industrial control setup, offering comprehensive control and monitoring features.

In industrial applications, efficient communication between operators and complex systems is essential. The DS200KLDBG1A addresses this need by providing a user – friendly platform that allows for easy input of commands and real – time monitoring of system status. It plays a pivotal role in ensuring the smooth operation of various industrial processes, from power generation to manufacturing.

Core advantages and technical highlights

1. Robust Input and Relay Channel Configuration

The board is equipped with 24 input channels, enabling it to gather a vast amount of data from different sensors and control inputs within the industrial system. This extensive data acquisition capability allows operators to monitor multiple operational parameters simultaneously. For example, in a large – scale manufacturing plant, these input channels can be connected to sensors that measure temperature, pressure, and speed of various machinery.

With 12 relay channels, the DS200KLDBG1A can effectively control a wide range of connected devices. These relays can switch electrical loads, activate alarms, or initiate specific actions based on the input received. In an industrial automation setup, the relay channels can be used to turn on or off motors, solenoid valves, or other equipment, enhancing the overall automation and response efficiency of the system.

2. Wide – Range Power Adaptability

Operating with a power requirement of +5V DC at 6A and a power supply voltage of 28V DC (with a range of 18 – 32V DC), the DS200KLDBG1A showcases remarkable power adaptability. This wide voltage range ensures that the board can function reliably even in environments where power fluctuations are common. In remote industrial locations or areas with inconsistent power grids, the board can continue to operate without disruption, maintaining the integrity of the control system.

3. Reliable Trip Solenoid Feature

The inclusion of a trip solenoid rated at 125V DC is a significant safety – oriented feature of the DS200KLDBG1A. In the event of an abnormal condition or a system trip, the trip solenoid can quickly and reliably actuate safety mechanisms. This is crucial in industrial settings where equipment protection and operator safety are of utmost importance. For instance, in a power generation plant, if there is a sudden over – voltage or over – current situation, the trip solenoid can trigger circuit breakers or other safety devices to prevent damage to expensive equipment and potential hazards to personnel.

4. Durable and Temperature – Resilient Design

Designed to withstand a wide temperature range from -40°C to 70°C, the DS200KLDBG1A is suitable for deployment in diverse industrial environments. Whether it’s an extremely cold mining operation in the Arctic or a hot and humid manufacturing facility in the tropics, the board can maintain its performance. The durable construction and temperature – resilient design ensure long – term reliability, reducing the need for frequent replacements and minimizing downtime.

Typical application scenarios

1. Power Generation Plants

In power generation plants, be it a gas – fired, coal – fired, or hydroelectric facility, the DS200KLDBG1A is used to monitor and control various aspects of the power generation process. Operators can use the keypad to input commands for adjusting the speed of turbines, regulating the flow of fuel or water, and monitoring the performance of generators. The display shows real – time data such as voltage, current, frequency, and temperature of critical components. In a 500 – MW gas – fired power plant, for example, the DS200KLDBG1A allows operators to make quick adjustments to the turbine’s operating parameters based on grid demand, ensuring efficient power generation and grid stability.

2. Manufacturing Facilities

Manufacturing plants rely on a complex network of machinery and automated systems. The DS200KLDBG1A serves as a central control interface for operators to manage production lines. It can be used to start or stop machines, adjust production speeds, and monitor the status of conveyor belts, robotic arms, and other equipment. In an automotive manufacturing plant, operators can use the board to control the speed of conveyor belts that transport car parts along the assembly line. The display can show information about the quantity of parts produced, the status of quality control checks, and any machine malfunctions, enabling timely intervention to maintain production efficiency.

3. Mining Operations

Mining operations involve heavy – duty equipment and harsh environmental conditions. The DS200KLDBG1A is used to control and monitor equipment such as crushers, conveyors, and pumps. Operators can use the keypad to start or stop these machines, adjust their operating parameters, and receive alerts in case of any mechanical failures or safety issues. In an open – pit copper mine, for example, the board can be used to control the speed of large – scale conveyor belts that transport copper ore from the mining site to the processing plant. The display can show information about the conveyor’s load, the temperature of the motor, and any blockages in the belt, ensuring continuous and efficient ore transportation.

GE DS200DSPCH1A

Related model recommendations

1. GE DS200ITXDG1A

While the DS200KLDBG1A focuses on display and control functions, the GE DS200ITXDG1A is more involved in communication and signal routing, especially in turbine excitation systems. In a power generation setup, the two can complement each other. The DS200ITXDG1A can transmit control signals related to turbine operation, and the DS200KLDBG1A can be used to display the status of these operations and receive operator commands for further adjustments.

2. GE Mark V Inverters

The DS200KLDBG1A is an integral part of the GE Mark V series, and when used in conjunction with Mark V inverters, it can enhance the overall control and monitoring capabilities of the system. Inverters in industrial applications are responsible for converting electrical power, and the DS200KLDBG1A can be used to monitor the performance of the inverters, adjust their output parameters, and receive alerts in case of any abnormal behavior. For example, in a textile manufacturing plant using Mark V inverters to control the speed of spinning machines, the DS200KLDBG1A can provide operators with real – time information about the inverter’s performance and allow for easy adjustment of the spinning speed.

3. GE DS200EXPSG1A

The GE DS200EXPSG1A is a power supply module. In a system where the DS200KLDBG1A is installed, a stable power supply is essential. The DS200EXPSG1A can provide the necessary power to the DS200KLDBG1A and other components in the system. In a water treatment plant, the DS200EXPSG1A can supply power to the control system, including the DS200KLDBG1A, which is used to monitor and control the pumps and other equipment involved in the water treatment process.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the DS200KLDBG1A, ensure that the entire industrial control system is powered off. Verify that the model of the control system is compatible with the DS200KLDBG1A. The required tools include a screwdriver (appropriate for the mounting screws), wire cutters, and a multimeter for basic electrical checks. Since the board is static – sensitive, it is crucial to take anti – static precautions. Wear an anti – static wristband and work on an anti – static mat. The installation location should be clean, dry, and within the specified temperature and humidity range.

Commissioning

Once installed, visually inspect all connections to ensure they are secure. Power on the control system gradually. Check the display on the DS200KLDBG1A to ensure it is functioning properly. Use diagnostic tools or software, if available, to test the input and relay channels. Send test signals to the input channels and check if the corresponding outputs are activated correctly. Monitor the board’s temperature during the initial operation. If it overheats or shows any abnormal behavior, immediately power off the system and troubleshoot the issue.

Maintenance suggestions

For regular maintenance, visually inspect the DS200KLDBG1A at least once a month. Look for any signs of physical damage, such as burned components, loose connections, or corrosion. Check the display for any pixel – related issues or incorrect readings. Every six months, use a multimeter to test the electrical parameters of the board, including power supply voltage, input and output signals. If any component shows signs of degradation or failure, replace it with a genuine GE replacement part. Keep the board clean by using a soft, dry brush to remove dust and debris, as accumulation of these can affect the board’s performance.

Service and guarantee commitment

GE offers a standard manufacturer’s warranty for the DS200KLDBG1A, which typically covers any defects in materials or workmanship under normal operating conditions. The exact duration of the warranty can be obtained from GE’s official documentation or customer service. If the board fails within the warranty period, GE will provide a replacement unit or repair the board free of charge, depending on the nature of the defect.

GE also has a global network of technical support teams. Customers can contact these teams for any installation, commissioning, or maintenance – related queries. The support teams are available during standard business hours (and in some cases, 24/7 for critical issues) to assist with troubleshooting and providing solutions. Additionally, GE may release product updates or technical bulletins from time to time, which can be accessed through GE’s official website or by registering the product with GE. These updates can help improve the performance and functionality of the DS200KLDBG1A and ensure its continued compatibility with evolving industrial control systems.