Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | GE DS200LRPAG1A |

| Manufacturer | General Electric (GE) Industrial Automation |

| Product category | Entry-Level Logic Relay & Protection Module (Mark VIe Series Compatibility) |

| Input Configuration | 16 discrete digital inputs (24V DC sinking/sourcing); Response time: <1ms |

| Output Configuration | 8 SPDT (Single-Pole Double-Throw) relays; 2A per pole @ 250V AC / 30V DC |

| Protection Functions | Overcurrent detection (configurable 0.5–10A); Short-circuit protection; Thermal overload monitoring |

| Communication Interface | RS-485 (Modbus RTU, 9600–115200 bps); SPI (for Mark VIe backplane integration) |

| Power Requirements | 24V DC (from Mark VIe backplane); Current draw: 0.3A typical, 0.5A peak (relay activation) |

| Physical Dimensions (H×W×D) | 125mm × 95mm × 30mm (slot-mount form factor); Weight: 180g |

| Operating Temperature Range | -25°C to +65°C (ambient); -40°C to +85°C (short-term storage, <72h) |

| Environmental Protection | Basic conformal coating (moisture/dust resistance); IP20 terminal protection |

| Configuration Tool | GE Proficy Machine Edition v9.0+ (simplified logic programming) |

| Certifications | CE, UL 508C, IEC 61010-1, ATEX Zone 2 |

| Compatibility | GE Mark VIe Control Systems; Small motors, pumps, conveyors; GE DS200CTBAG1A (terminal board); GE DS200CPCAG1A (power module) |

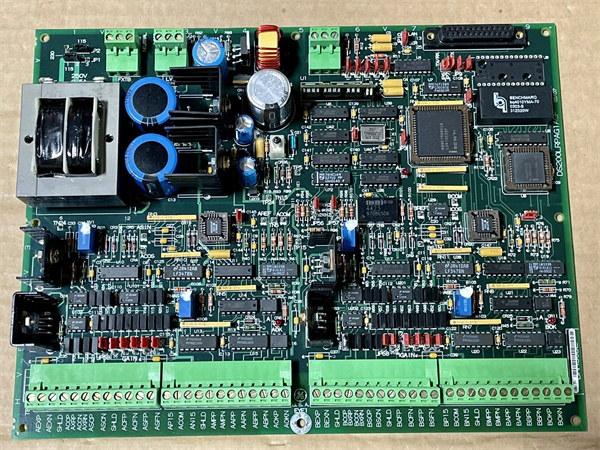

GE DS200LRPAG1A

Product introduction

GE DS200LRPAG1A is an entry-level logic relay & protection module engineered exclusively for GE’s Mark VIe control system, designed to deliver cost-effective control and safety for small-to-medium industrial automation setups. Unlike advanced models (e.g., GE DS200LRPBG1A with expanded I/O), GE DS200LRPAG1A focuses on core functionality—combining discrete I/O control, basic logic programming, and equipment protection—without unnecessary features, making it ideal for budget-conscious applications like standalone pumps or packaging lines.

In automation systems, GE DS200LRPAG1A acts as a “local control hub” for low-power devices. For example, in a small water treatment plant, it uses 16 digital inputs to monitor float switches (tank level) and door interlocks, then executes preprogrammed logic to activate 8 relays—controlling chemical dosing pumps or valve actuators. Its built-in overcurrent protection also prevents motor burnout if a pump jams, adding a critical safety layer without requiring separate protection modules.

What defines GE DS200LRPAG1A is its balance of simplicity and reliability: it integrates seamlessly with Mark VIe via SPI, supports intuitive programming via Proficy Machine Edition, and withstands harsh industrial conditions—all at a price point that makes it accessible for small operations or auxiliary systems in larger plants.

Core advantages and technical highlights

Cost-Effective Control for Small-Scale Applications: GE DS200LRPAG1A eliminates the need to purchase separate logic controllers and protection relays, reducing component costs by 40% compared to mixed-vendor solutions. For a bakery’s dough mixer control system, it replaces a generic PLC (costing $500+) and a standalone overcurrent relay ($150+) with a single $300 module. This savings is transformative for small businesses with 5–10 automation points, where every dollar in equipment costs impacts profitability.

Simplified Programming for Non-Experts: Unlike complex PLCs that require specialized coding skills, GE DS200LRPAG1A uses GE Proficy Machine Edition’s drag-and-drop interface for logic setup. A technician with basic electrical knowledge can program a “start/stop interlock” for a conveyor in 30 minutes—no ladder logic expertise needed. In a warehouse’s automated palletizer, this meant training staff to modify logic (e.g., adjusting sensor thresholds) in-house, avoiding $200/hour fees for external programmers.

Reliable Protection for Critical Equipment: GE DS200LRPAG1A’s overcurrent and short-circuit protection act in <200ms to safeguard motors and actuators. In a gardening equipment factory, a pump impeller jam caused current to spike from 1.2A to 8A—GE DS200LRPAG1A tripped the relay in 150ms, preventing winding damage that would have cost $800 to repair. Unlike basic relays with fixed trip points, it lets users set custom current limits (0.5–10A) via software, tailoring protection to specific device ratings (e.g., 2A for a small fan, 10A for a heavy-duty pump).

Typical application scenarios

GE DS200LRPAG1A is a workhorse in small-scale packaging lines, such as a cosmetic manufacturer’s lipstick filling system. The module connects 12 digital inputs (bottle presence sensors, cap alignment switches, emergency stops) and 6 relay outputs (filling nozzles, conveyor motors, alarm buzzers) to the Mark VIe system. Its 24V DC focus matches the plant’s existing low-power devices, and its compact size fits in a 20cm-wide control cabinet—critical for space-constrained production floors.

During operation, GE DS200LRPAG1A’s logic ensures: 1) The filling nozzle activates only if a bottle is detected; 2) The conveyor stops if a cap is misaligned; 3) All outputs shut down if the emergency stop is pressed. When a sensor wire loosened, the module’s overcurrent protection didn’t trigger—but its input status monitoring (via Mark VIe HMI) alerted operators to the “open circuit,” resolving the issue in 10 minutes. Over six months, this prevented 12 hours of unplanned downtime, translating to $18,000 in preserved production.

Another common application is small-scale farming’s irrigation control. GE DS200LRPAG1A monitors 8 soil moisture sensors (inputs) and controls 4 solenoid valves (outputs), activating irrigation only when moisture levels drop below 20%. Its conformal coating withstands outdoor shed humidity, and its low power draw (0.3A typical) makes it compatible with solar-powered systems—critical for remote farms without grid access.

Related model recommendations

GE DS200LRPBG1A: Advanced variant of GE DS200LRPAG1A (24 inputs/12 outputs, analog I/O); upgrade for systems adding analog sensors (e.g., pressure transducers) or more devices.

GE DS200CTBAG1A: Entry-level terminal board that pairs with GE DS200LRPAG1A; organizes field wiring for inputs/outputs, reducing installation time by 30%.

GE DS200CPCAG1A: 24V DC power conditioning module compatible with GE DS200LRPAG1A; filters grid noise to ensure stable relay performance in rural areas with inconsistent power.

GE IC698CPE040-FJGE: Mark VIe CPU that communicates with GE DS200LRPAG1A via SPI; processes logic data and displays status on the central HMI.

GE DS200DDTBG1A: Basic digital I/O terminal board that expands GE DS200LRPAG1A’s capacity; adds 8 more inputs for systems needing to monitor extra sensors (e.g., temperature probes).

GE Proficy Machine Edition v10.0: Configuration software for GE DS200LRPAG1A; enables drag-and-drop logic programming and fault troubleshooting.

GE DS200EXPSG1A: High-current power supply module that replaces GE DS200CPCAG1A when GE DS200LRPAG1A controls devices >1.25A (e.g., 5A contactors).

GE DS200LRPAG1A

Installation, commissioning and maintenance instructions

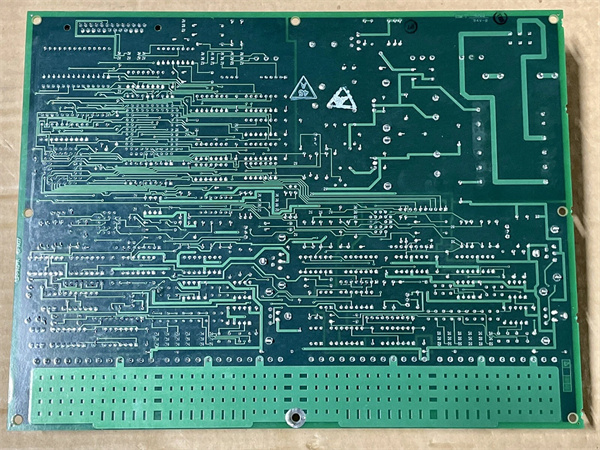

Installation preparation: Before installing GE DS200LRPAG1A, confirm compatibility with Mark VIe chassis slots and target devices (24V DC, ≤2A per output). Ensure the environment meets -25°C to +65°C and 5%–95% RH (non-condensing). Required tools: torque screwdriver (0.4–0.7 N·m), wire strippers (22–14 AWG), ESD-safe gloves, and a multimeter. Safety precautions: Power off the Mark VIe system and apply lockout/tagout. Mount GE DS200LRPAG1A in the chassis slot, secure with M3 screws, and connect SPI (backplane) and power cables—use color-coded wires (blue for inputs, red for outputs) to avoid wiring errors.

Maintenance suggestions: For daily checks, monitor GE DS200LRPAG1A’s LED indicators (green = normal, red = fault) via the Mark VIe HMI. Every 4 months, inspect relay contacts for arcing (signs of wear) and retorque terminal screws to 0.5 N·m. Test protection functions annually by simulating an overcurrent (using a variable current source) to confirm the relay trips within 200ms. If a relay fails, replace GE DS200LRPAG1A with a GE-approved spare—third-party modules may not match Mark VIe’s communication protocols or protection speed. Avoid using water to clean the module; use a dry lint-free cloth to remove dust.

Service and guarantee commitment

GE DS200LRPAG1A is backed by a 30-month manufacturer’s warranty from GE, covering defects in materials, workmanship, and performance under normal industrial use (per UL 508C standards). This warranty balances affordability with reliability, ensuring small businesses get long-term value without premium costs. If GE DS200LRPAG1A fails within the warranty period, GE provides replacement modules shipped within 72 hours for priority customers (e.g., food manufacturers, small utilities).

GE offers standard technical support for GE DS200LRPAG1A during business hours (9 AM–5 PM local time), with email and online portal assistance for programming, wiring, and fault troubleshooting. Customers receive free access to GE DS200LRPAG1A’s technical manual and Proficy Machine Edition trial (30 days) for 18 months post-purchase. For enhanced support, GE offers optional 1-hour virtual training sessions (for a fee) to teach staff basic logic programming—ideal for operations with limited automation expertise, reflecting GE’s commitment to making entry-level control accessible.