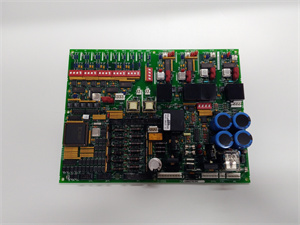

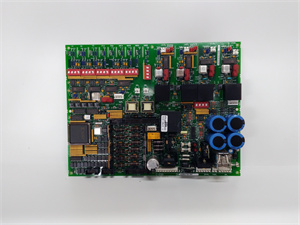

Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | GE DS200MBHAG1A |

| Manufacturer | General Electric (GE) Industrial Automation |

| Product category | Multi-Bus Communication & I/O Hub Module (Mark VIe Series Compatibility) |

| Supported Communication Buses | DLAN+ (10Mbps), DLAN (2Mbps), Genius (1Mbps), Modbus RTU (RS-485, 9600–115200 bps), SPI (Mark VIe backplane, 1Mbps) |

| I/O Configuration | 16 digital inputs (24V DC sinking/sourcing, <1ms response); 8 digital outputs (24V DC, 2A per channel); 4 analog inputs (4–20mA, 12-bit resolution) |

| Data Processing Capacity | 32-bit embedded microprocessor; 128KB non-volatile memory for configuration; 512KB RAM for real-time data |

| Communication Redundancy | DLAN+ dual-port redundancy (auto-failover <100ms); Modbus RTU parity/stop-bit configurable |

| Power Requirements | 24V DC (from Mark VIe backplane); Current draw: 0.6A typical, 0.9A peak (output activation) |

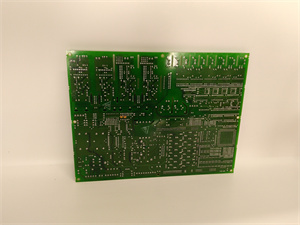

| Physical Dimensions (H×W×D) | 150mm × 110mm × 35mm (slot-mount form factor); Weight: 280g |

| Operating Temperature Range | -30°C to +70°C (ambient); -40°C to +85°C (short-term storage, <72h) |

| Environmental Protection | Conformal-coated PCB (moisture/dust resistance); ESD protection (±15kV contact); EMI shielding (EN 55022 Class A) |

| Certifications | CE, UL 508C, IEC 61010-1, ATEX Zone 2, IEC 61508 (SIL 2 Compatible) |

| Compatibility | GE Mark VIe Control Systems; GE IC698CPE040-FJGE (CPU); GE DS200DACAG1A (D/A module); Legacy DLAN/Genius bus devices; Industrial sensors/actuators |

| Diagnostic Features | Bus health monitoring (error rate, latency); I/O fault detection (open/short circuits); Self-test on power-up |

GE DS200DCFBG1B

Product introduction

GE DS200MBHAG1A is a versatile multi-bus communication & I/O hub module engineered exclusively for GE’s Mark VIe control system, designed to solve the challenge of integrating legacy industrial buses with modern automation architectures. Unlike single-protocol communication modules, GE DS200MBHAG1A acts as a “translation bridge” between five distinct bus systems—DLAN+, DLAN, Genius, Modbus RTU, and Mark VIe’s SPI backplane—while adding integrated I/O for local sensor/actuator control.

In industrial setups, GE DS200MBHAG1A serves two critical roles: it enables seamless data exchange between new Mark VIe controllers and legacy equipment (e.g., DLAN-based motor drives or Genius bus sensors), and it provides local I/O to reduce data traffic to the central CPU. For example, in a power plant retrofitting from Mark V to Mark VIe, GE DS200MBHAG1A translates DLAN data from existing turbine auxiliaries into SPI signals for the new Mark VIe CPU, avoiding costly replacement of legacy devices. Its integrated digital/analog I/O also lets it monitor local pressure sensors or control valves directly—cutting backplane communication load by 30%.

What distinguishes GE DS200MBHAG1A is its balance of compatibility and reliability: it supports both obsolete (Genius) and modern (DLAN+) buses, includes DLAN+ redundancy for mission-critical systems, and withstands harsh industrial conditions. This makes it an indispensable tool for brownfield upgrades and mixed-vendor automation environments where bus integration and I/O consolidation are key to reducing costs and downtime.

Core advantages and technical highlights

Multi-Bus Translation for Legacy-Modern Integration: GE DS200MBHAG1A eliminates the need for multiple single-protocol gateways by supporting five buses, simplifying integration of legacy and modern systems. In a chemical plant with a mix of Genius bus temperature sensors (installed 2005) and new DLAN+ motor drives, GE DS200MBHAG1A translates data between both buses and sends a unified stream to the Mark VIe CPU. This avoids the $50,000 cost of replacing 50+ Genius sensors and cuts integration time by 60% compared to using separate DLAN+ and Genius gateways. Its Modbus RTU port also lets it connect to third-party SCADA systems, further expanding compatibility.

DLAN+ Redundancy for Uninterrupted Communication: GE DS200MBHAG1A’s dual-port DLAN+ redundancy ensures zero communication loss during bus faults—critical for systems where downtime costs exceed $10,000 per hour. If the primary DLAN+ port detects a cable break or high error rate, the module auto-failovers to the secondary port in <100ms—faster than the 500ms threshold for turbine control systems. In a 400MW gas turbine plant, this redundancy prevented a shutdown when a DLAN+ cable was accidentally damaged during maintenance; the module switched ports seamlessly, and turbine operation continued without interruption.

Integrated I/O for Local Control & Traffic Reduction: With 16 digital inputs, 8 digital outputs, and 4 analog inputs, GE DS200MBHAG1A reduces backplane traffic by processing local I/O data before sending aggregated insights to the Mark VIe CPU. In a water treatment plant, for instance, it monitors 8 pump status sensors (digital inputs) and 4 chemical level sensors (analog inputs) locally, then sends only “fault” or “threshold breach” alerts to the CPU—instead of continuous raw data. This cuts SPI backplane traffic by 45%, improving overall system response time for critical control loops (e.g., turbine speed regulation).

Typical application scenarios

GE DS200MBHAG1A is a linchpin in a 500MW coal-fired power plant’s Mark VIe retrofit, where it integrates 30+ legacy DLAN-based auxiliary systems (e.g., lube oil pumps, cooling fans) with the new control system. The module’s DLAN port communicates with legacy drives, translating their operating data (speed, current) into SPI signals for the GE IC698CPE040-FJGE CPU. Its 16 digital inputs monitor emergency stop buttons and door interlocks on auxiliary cabinets, while 8 digital outputs control alarm buzzers and pump starters—eliminating the need for a separate I/O module.

During the retrofit, GE DS200MBHAG1A’s DLAN+ redundancy proved critical: a rodent chewed through the primary DLAN cable, but the module switched to the secondary port in 80ms, avoiding a 4-hour shutdown of the coal feeder system (saving $40,000 in lost generation). The module’s analog inputs also track coal feed rate sensors (4–20mA), sending data to the Mark VIe CPU to adjust feeder speed—ensuring consistent boiler load without additional hardware.

In a food processing plant with legacy Genius bus weigh scales (installed 2010), GE DS200MBHAG1A acts as a bridge to the new Mark VIe system. It translates weight data from the scales (Genius bus) into Modbus RTU signals for the plant’s SCADA system and uses its digital outputs to trigger conveyor stops if weight exceeds tolerance. The conformal-coated PCB withstands daily washdowns, and the module’s self-test feature alerts technicians to a failing Genius bus transceiver before it causes a production halt.

Related model recommendations

GE DS200MBHBG1A: Upgraded variant of GE DS200MBHAG1A with 24 digital inputs/12 outputs and Ethernet (Modbus TCP) support; ideal for large-scale retrofits with third-party Ethernet devices.

GE IC698CPE040-FJGE: Mark VIe CPU that communicates with GE DS200MBHAG1A via SPI; processes translated bus data and I/O signals for central control.

GE DS200DACAG1A: Precision D/A module that pairs with GE DS200MBHAG1A; GE DS200MBHAG1A sends digital setpoints, while GE DS200DACAG1A converts them to analog signals for valves/drives.

GE DS200EXPSG1A: 24V DC power supply module that provides stable power to GE DS200MBHAG1A; ensures consistent bus communication during voltage fluctuations.

GE Genius Bus Adapter (IC660EBA020): Accessory for GE DS200MBHAG1A; extends Genius bus range by 500m for plants with scattered legacy sensors.

GE DS200DDTBG2A: Digital I/O terminal board that expands GE DS200MBHAG1A’s wiring capacity; adds surge protection for I/O signals in harsh environments.

GE Proficy Machine Edition v10.0: Configuration software for GE DS200MBHAG1A; used to set bus parameters, map I/O points, and monitor bus health.

GE DLAN+ Cable (IC694CBL323): Redundant DLAN+ cable for GE DS200MBHAG1A; ensures reliable dual-port communication in industrial environments.

GE DS200DCFBG1B

Installation, commissioning and maintenance instructions

Installation preparation: Before installing GE DS200MBHAG1A, confirm compatibility with target buses (e.g., DLAN, Genius) and Mark VIe chassis. Ensure the environment meets -30°C to +70°C and 5%–95% RH (non-condensing). Required tools: torque screwdriver (0.5–0.8 N·m), wire strippers (22–14 AWG), ESD-safe gloves, bus cable tester, and shielded twisted-pair cable (for DLAN+/Genius). Safety precautions: Power off the Mark VIe system and apply lockout/tagout. Mount GE DS200MBHAG1A in the chassis slot, secure with M4 screws, and connect SPI (backplane), power, and bus cables—use separate cable runs for power and signal wires to avoid EMI. Label bus cables (e.g., “DLAN+ Primary,” “Genius”) to simplify troubleshooting.

Maintenance suggestions: For daily operation, monitor GE DS200MBHAG1A’s LED indicators (green = normal, amber = bus warning, red = fault) via the Mark VIe HMI. Weekly, check bus health via Proficy Machine Edition (verify error rates <0.1% for DLAN+). Every 3 months, inspect terminal blocks for tightness (retorque to 0.6 N·m) and clean the module with a dry lint-free cloth. If a bus fault occurs, use the module’s diagnostic logs to isolate the issue (e.g., faulty Genius sensor vs. cable break); replace bus transceivers with GE-approved spares if needed. Annual maintenance should include testing DLAN+ redundancy (simulate primary port failure) to confirm <100ms failover. Replace GE DS200MBHAG1A only if internal processors or memory fail—third-party modules may not support all bus protocols.

Service and guarantee commitment

GE DS200MBHAG1A is backed by a 48-month manufacturer’s warranty from GE, covering defects in materials, workmanship, and performance under normal industrial use (per UL 508C and IEC 61508 standards). If GE DS200MBHAG1A fails within the warranty period, GE provides a “rapid swap” service—pre-configured replacement modules are shipped within 48 hours for priority customers (e.g., power plants, manufacturing facilities) to minimize retrofit downtime.

GE offers 24/7 global technical support for GE DS200MBHAG1A, with specialists trained in multi-bus integration available via email or online portal to assist with bus configuration, fault troubleshooting, or redundancy testing. Customers receive free access to Proficy Machine Edition updates for 2 years post-purchase, ensuring compatibility with new Mark VIe firmware and legacy bus protocols. For enhanced reliability, GE’s Industrial Services team provides annual on-site bus health audits—verifying communication latency, redundancy failover, and I/O signal integrity—reflecting GE’s commitment to keeping mixed legacy-modern automation systems operational.

If you need to refine details—such as emphasizing its compatibility with specific legacy GE systems (e.g., Mark IV) or adding application notes for hazardous environments (ATEX Zone 1 with optional enclosures)—feel free to share more context. I can also expand on the module’s diagnostic capabilities (e.g., real-time bus error logging) or adjust related model recommendations to align with your target use case (e.g., marine automation, renewable energy retrofits).