Description

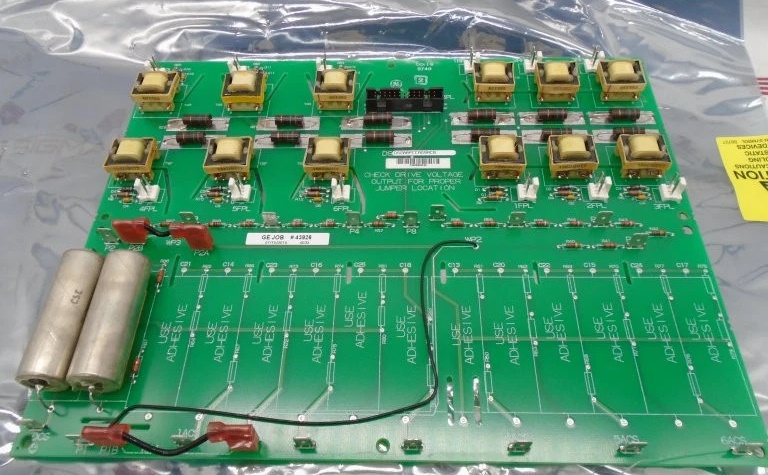

DS200PCCAG9A: Product Overview

The GE DS200PCCAG9A is a power connect card (PCCA) designed for GE’s Mark V series of turbine control systems. It serves as a critical interface between the SCR (Silicon Controlled Rectifier) bridge of M-frame drives and downstream power supply/connection cards (e.g., DCFB, SDCI), enabling reliable power distribution and signal transmission in gas turbine applications.

Role in Automation Systems:

Positioned as the “power gateway” in M-frame drive systems, the DS200PCCAG9A performs two primary functions:

-

Signal Conversion: Transforms low-level shunt signals (from the SCR bridge) into high-frequency differential outputs (0–500 kHz) using a voltage-controlled oscillator (VCO) circuit. This conversion is essential for downstream power supply boards to interpret and regulate power flow.

-

Current Regulation: Integrates a 10:1 current transformer (ACCT) to attenuate line current, protecting sensitive downstream components (e.g., load resistors on SDCI/DCFB boards) from overcurrent damage.

Core Functionality:

-

Shunt Signal Processing: Accepts shunt signals ranging from -500 mV to +500 mV (DC positive/negative floating shunts) and converts them to 0–500 kHz differential frequency outputs. This process ensures that the power supply board receives accurate, noise-free signals for voltage regulation.

-

Attenuation Configuration: Uses 17 onboard jumpers to select attenuation settings for the AC line current transformer. For example:

-

Bypass Mode: Enabled when line voltage is 240–600 VAC (no attenuation).

-

Enable Mode: Activated when line voltage exceeds 600 VAC (10:1 attenuation to protect downstream components).

-

-

Electrical Isolation: Provides galvanic isolation between the SCR bridge and downstream circuits, preventing ground loops and voltage spikes from damaging sensitive electronics.

Platform Benefits (Mark V Series):

The DS200PCCAG9A leverages GE’s Mark V platform, which is renowned for:

-

Reliability: Industrial-grade components and a rugged design ensure 24/7 operation in harsh turbine hall environments (e.g., high temperature, vibration).

-

Scalability: Supports expansion with additional interface boards or power supply cards to accommodate growing system demands (e.g., adding more drives to a turbine).

-

Integration: Seamlessly integrates with GE’s M-frame drives and Mark V control systems, reducing setup time and effort for engineers.

GE DS200PCCAG9A

Technical Specifications

-

Model Number: DS200PCCAG9A

-

Manufacturer: GE (General Electric)

-

Product Type: Power Connect Card (PCCA)

-

Series: Mark V

-

Signal Conversion:

-

Input: -500 mV to +500 mV (shunt signals)

-

Output: 0–500 kHz (differential frequency)

-

-

Current Transformer (ACCT): 10:1 attenuation (user-selectable via jumpers)

-

Protection Features: ESD protection, overvoltage protection

-

Operating Temperature: -40°C to +85°C (industrial-grade)

-

Storage Temperature: -40°C to +85°C

-

Humidity: 5–95% non-condensing

-

Dimensions: 82 mm × 122 mm × 60 mm (approx.)

-

Weight: 0.36 kg (approx.)

-

Certifications: CE, UL (inferred from GE industrial product standards)

Core Features & Customer Value

1. Precise Signal Conversion:

The DS200PCCAG9A’s VCO circuit ensures accurate conversion of shunt signals to differential frequency outputs, which is critical for maintaining stable power flow in turbine drives. For example, in a gas turbine, this precision prevents voltage fluctuations that could damage the generator or other equipment.

2. Flexible Attenuation Configuration:

The 17 onboard jumpers allow engineers to customize attenuation settings based on line voltage, ensuring that downstream components are protected from overcurrent. This flexibility reduces the need for additional hardware modifications, saving time and money during installation.

3. Rugged Industrial Design:

The board’s operating temperature range (-40°C to +85°C) and compact form factor make it suitable for harsh turbine hall environments. Its rugged construction resists vibration and dust, ensuring reliable operation even in challenging conditions.

4. Seamless Integration with Mark V:

Designed specifically for GE’s Mark V series, the DS200PCCAG9A integrates with existing M-frame drives and control systems without requiring custom configuration. This reduces setup time and ensures compatibility with legacy systems, which is critical for power plants and industrial facilities.

GE DS200PCCAG9A

Typical Applications

The GE DS200PCCAG9A is widely used in gas turbine control systems for:

-

Power Generation:

-

Interfaces with M-frame drives in gas turbines to convert shunt signals from the SCR bridge to differential frequency outputs, enabling stable power generation.

-

Example: In a combined-cycle power plant, the board ensures that the gas turbine’s power output is regulated correctly, maintaining grid stability.

-

-

Industrial Automation:

-

Serves as an interface between M-frame drives and power supply cards in industrial automation systems, ensuring reliable signal transmission for motor control and process monitoring.

-

Example: In a steel mill, the board is used in the drive system for a rolling mill, converting signals from the SCR bridge to regulate the mill’s speed.

-

-

Turbine Drive Systems:

-

Provides signal conversion and current regulation for M-frame drives in turbine applications, protecting downstream components from overcurrent and voltage spikes.

-

Example: In a wind turbine, the board is used in the drive system to convert signals from the SCR bridge, ensuring that the turbine’s generator operates efficiently.

-