Description

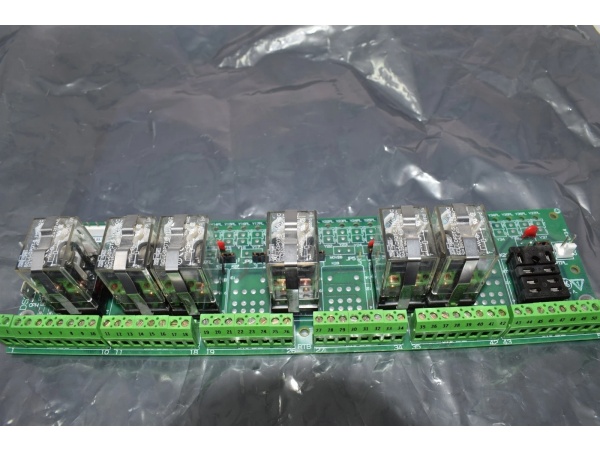

DS200RTBAG4AHC: Product Overview

Role in Automation Systems

-

Field Contact Aggregation: Connects field contacts (e.g., oil-pressure switches, breaker status) to the Mark V rack via 190 screw terminals, eliminating the need for multiple DIN-rail relays.

-

Excitation Relay Support: Interfaces with excitation relays (e.g., 115 VAC auxiliary relays) to provide power to turbine drive systems, ensuring reliable actuation of critical components.

Core Functionality

-

Flexible Coil Voltage Configuration: Jumper-selectable coil voltage (115 VAC, 24 VDC, or 125 VDC) allows adaptation to different field devices, reducing the need for additional voltage converters.

-

High Isolation Rating: 2 kV coil-to-logic and 500 V contact-to-contact isolation protect sensitive Mark V electronics from high-voltage transients, ensuring reliable operation in harsh industrial environments.

-

Compact Form Factor: VME-style design (159 × 178 mm, 0.7 kg) fits into standard Mark V racks, minimizing panel space usage and simplifying installation.

-

Easy Maintenance: Plug-in design allows for quick replacement during maintenance, reducing downtime. The 190-position screw-terminal block simplifies field wiring, with clear labeling for easy troubleshooting.

DS200RTBAG4AHC

Technical Specifications

-

Model Number: DS200RTBAG4AHC (Variant of Mark V Series)

-

Manufacturer: GE (General Electric)

-

Product Type: Relay Terminal Board

-

Series: Mark V (Turbine Control Systems)

-

Relay Type: RST (Regulator, Sensor, Transducer)

-

Terminal Count: 190-position screw-block (95 per side)

-

Coil Voltage: Jumper-selectable (115 VAC 50/60 Hz, 24 VDC, 125 VDC)

-

Isolation: 2 kV basic coil-to-logic; 500 V contact-to-contact

-

Connector: 96-pin DIN 41612 to VME back-plane; screw terminals for field wires

-

Operating Temperature: –40 °C to +70 °C (industrial-grade)

-

Dimensions: 159 × 178 mm (VME-style)

-

Weight: 0.7 kg (typical)

-

Protection Degree: IP20 (rack-mount)

Core Features & Customer Value

DS200RTBAG4AHC

Typical Applications

-

Power Generation:

-

Connects field contacts (e.g., oil-pressure switches, breaker status) and excitation relays in gas/steam turbine control systems, reducing wiring complexity and improving reliability.

-

-

Heavy Industry:

-

Used in manufacturing facilities to aggregate field relays for critical processes (e.g., conveyor belts, pumps), ensuring reliable actuation of components.

-

-

Oil & Gas:

-

Deployed in refineries and drilling platforms to connect field contacts for safety interlocks, ensuring safe and efficient operation in hazardous environments.

-