Description

DS200RTBAG5AHC: Product Overview

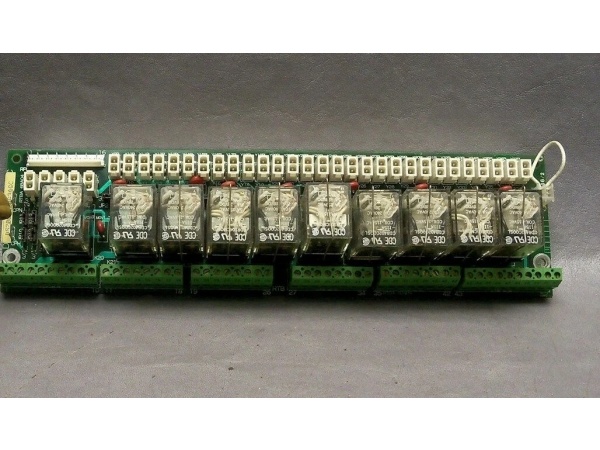

The GE DS200RTBAG5AHC is a relay terminal board designed specifically for GE Speedtronic™ Mark V distributed control systems (DCS), the industry standard for gas, steam, and hydro turbine control in power generation. As part of the Mark V ecosystem, it acts as a “signal aggregator” for relay operations, consolidating control logic from the Mark V rack to external devices (e.g., oil-pressure switches, breaker status, 115 VAC auxiliary contacts).

Engineered for the demanding conditions of turbine halls, the DS200RTBAG5AHC features a compact VME-style form factor and rugged screw-terminal connections, withstanding vibration, dust, and moisture. Its legacy compatibility makes it ideal for retrofitting aging Mark V systems—common in power plants operating turbines for 20+ years—where replacing entire control architectures is cost-prohibitive. Whether used in 7EA or 9F peakers, the DS200RTBAG5AHC ensures reliable relay switching, directly extending the operational life of critical turbine control systems.

Role in Automation Systems

Positioned as a “field-to-rack relay interface” in Mark V architectures, the DS200RTBAG5AHC performs two primary functions:

-

Relay Control: Executes relay operations (on/off) based on pilot relay inputs or remote commands from the Mark V controller. For example, it can trigger a fuel valve actuator when a turbine speed threshold is exceeded.

-

Signal Interfacing: Connects control logic from the Mark V rack to external devices (e.g., switches, sensors), enabling seamless communication between the controller and field equipment.

Its core value lies in reducing wiring complexity—a major pain point in turbine control panels—while maintaining signal integrity through reliable relay switching and screw-terminal connections.

Core Functionality

-

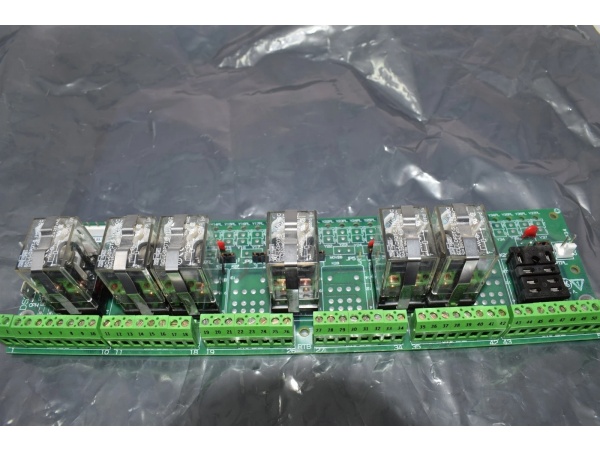

Flexible Relay Configuration: 10 relays (K20–K29) with mixed DPDT (6 relays) and 4PDT (3 relays) types, allowing adaptation to different field devices. For example, DPDT relays are used for simple on/off control, while 4PDT relays handle more complex switching requirements.

-

LED Indicators: Each relay includes an LED that illuminates when energized, providing instant visual feedback on relay status. This simplifies troubleshooting—technicians can quickly identify faulty relays without using multimeters.

-

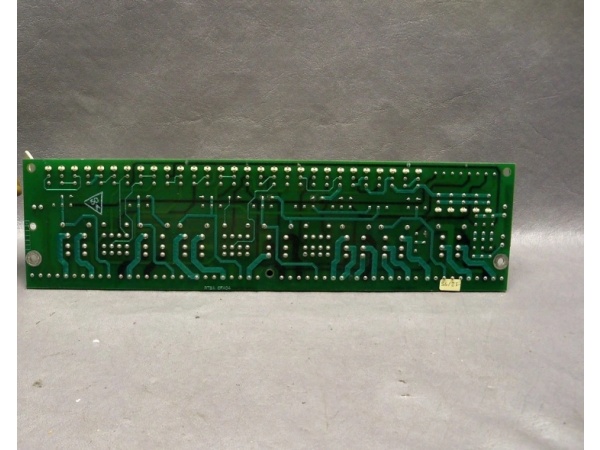

Secure Wiring: Screw-type terminals ensure stable connections to field wires, preventing loose connections that could cause intermittent faults. The 16-pin and 2-pin connectors facilitate easy integration with the Mark V rack.

-

Rugged Design: The VME-style form factor (150 mm × 115 mm × 32 mm) and normal PCB coating protect against dust, moisture, and vibration—common in turbine hall environments. The board’s operating temperature range (-40°C to +70°C) ensures reliable operation in extreme climates.

DS200RTBAG4AHC

Technical Specifications

|

Parameter

|

Specification

|

|---|---|

|

Model Number

|

DS200RTBAG5AHC

|

|

Manufacturer

|

General Electric (GE)

|

|

Product Type

|

Relay Terminal Board (RTBA)

|

|

Series

|

Mark V (Turbine Control Systems)

|

|

Relay Count

|

10 relays (K20–K29)

|

|

Relay Types

|

K20–K26: DPDT; K27–K29: 4PDT

|

|

Connectors

|

1× 16-pin connector, 1× 2-pin connector

|

|

Terminal Type

|

Screw-type terminals

|

|

Mounting

|

Rack-mounted inside the drive cabinet

|

|

PCB Coating

|

Normal coating (dust/moisture resistant)

|

|

Operating Temperature

|

-40°C to +70°C (industrial-grade)

|

|

Storage Temperature

|

-40°C to +85°C

|

|

Weight

|

~0.3 kg (0.66 lbs)

|

|

Certifications

|

CE, UL (inferred from GE industrial product standards)

|

Core Features & Customer Value

1. Reduced Wiring Complexity:

By consolidating 10 relays into a single board, the DS200RTBAG5AHC eliminates the need for multiple DIN-rail relay blocks, reducing wiring time and potential failure points. This is particularly valuable in retrofit projects, where minimizing downtime is critical.

2. High Reliability:

The board’s screw-terminal connections and rugged VME-style form factor ensure reliable operation in harsh industrial environments. For example, in a power plant, the DS200RTBAG5AHC can withstand the vibration from nearby turbines and the electromagnetic interference (EMI) from high-voltage equipment.

3. Easy Troubleshooting:

The LED indicators for each relay provide instant visual feedback on relay status. If a fault occurs (e.g., a relay fails to energize), the corresponding LED will not illuminate, allowing technicians to quickly identify and replace the faulty relay.

4. Legacy Compatibility:

The DS200RTBAG5AHC is designed to work with existing Mark V components (e.g., I/O racks, controllers), reducing the cost of system upgrades. This makes it an ideal choice for power plants with aging Mark V systems, where replacing the entire control architecture is not feasible.

DS200RTBAG4AHC

Typical Applications

The GE DS200RTBAG5AHC is widely used in industrial automation systems for:

-

Power Generation:

-

Connects control logic from Mark V controllers to external devices (e.g., fuel valve actuators, oil-pressure switches) in gas/steam turbine control systems.

-

-

Heavy Industry:

-

Used in manufacturing facilities to aggregate relay signals for critical processes (e.g., conveyor belts, pumps), ensuring reliable actuation of components.

-

-

Oil & Gas:

-

Deployed in refineries and drilling platforms to connect control logic to safety interlocks, ensuring safe and efficient operation in hazardous environments.

-