Description

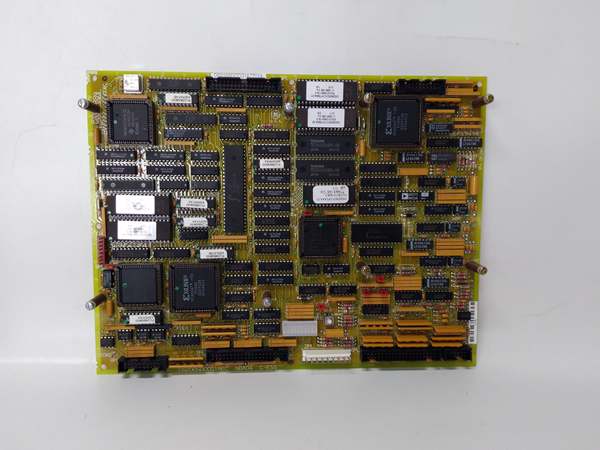

DS200SDCCG1AEC: Product Overview

The GE DS200SDCCG1AEC is a drive control board designed specifically for GE Speedtronic™ Mark V distributed control systems (DCS), the industry standard for gas, steam, and hydro turbine control in power generation. As the “brain” of the Mark V drive system, it integrates three microprocessors to manage complex control tasks—from real-time speed regulation to fault detection—ensuring stable turbine operation in harsh industrial environments.

Role in Automation Systems:

Positioned as the core drive controller in Mark V architectures, the DS200SDCCG1AEC performs three primary functions:

-

Drive Control: Executes PID loops and turbine-specific algorithms to maintain optimal speed and load, adjusting fuel flow or steam inlet valves based on sensor feedback.

-

I/O Management: Processes signals from field devices (e.g., LVDT for valve position, thermocouples for exhaust temperature) and sends control commands to actuators (e.g., servo valves for fuel regulation).

-

Fault Protection: Monitors for abnormal conditions (e.g., overspeed, low lubrication pressure) and triggers shutdown sequences to prevent turbine damage.

Core Functionality:

-

Triple Microprocessor Architecture:

-

Drive Control Microprocessor: Manages built-in functions (e.g., speed setpoint tracking) and user interface software.

-

High-Speed I/O Microprocessor: Handles fast digital/analog I/O and digital timers for real-time signal processing.

-

Motor Control Microprocessor: Performs math-intensive calculations (e.g., torque compensation) for precise motor/drive operation.

-

-

Shared RAM: Allows simultaneous access by all microprocessors, ensuring coordinated control and minimal latency.

-

Auxiliary Board Support: Accommodates additional cards (e.g., LAN communication, signal processing) to expand functionality without replacing the core board.

-

Diagnostic LEDs: Provides visual feedback on board status (e.g., power, communication, fault codes) for easy troubleshooting.

Platform Benefits (Mark V Series):

The DS200SDCCG1AEC inherits the Mark V platform’s strengths, including:

-

Reliability: Proven 24/7 operation in power plants worldwide, with a track record of minimizing unplanned downtime.

-

Legacy Compatibility: Works with existing Mark V components (e.g., I/O racks, terminal boards), reducing the cost of system upgrades.

-

Scalability: Supports expansion with auxiliary boards to accommodate growing system demands (e.g., adding more sensors or actuators).

DS200SDCCG1AEC

Technical Specifications

-

Model Number: DS200SDCCG1AEC (Variant of Mark V Series)

-

Manufacturer: GE (General Electric)

-

Product Type: Drive Control Board

-

Series: Mark V (Gas/Steam Turbine Control)

-

Form Factor: 6U Eurocard (160 mm × 233 mm)

-

Bus Standard: VMEbus Rev. C.1 (compatible with Mark V I/O racks)

-

Microprocessors: 3 (dedicated to drive control, high-speed I/O, motor math)

-

Memory: Shared RAM (size varies by configuration)

-

I/O Channels: Configurable (digital/analog inputs/outputs for sensors/actuators)

-

Operating Temperature: 0°C to +60°C (industrial-grade)

-

Storage Temperature: -40°C to +85°C

-

Humidity: 5–95% non-condensing

-

Weight: ~0.45 kg (1 lb)

-

Certifications: CE, UL (inferred from GE industrial product standards)

Core Features & Customer Value

1. Precise Drive Control:

The triple microprocessor architecture ensures accurate speed regulation and load following, critical for power generation where even minor deviations can impact grid stability. For example, in a gas power plant, the DS200SDCCG1AEC adjusts fuel flow based on turbine speed feedback, maintaining optimal efficiency and reducing emissions.

2. Flexible I/O Handling:

Supports a wide range of digital/analog I/O, allowing engineers to connect diverse field devices (e.g., LVDT, thermocouples, servo valves) without additional signal conditioning hardware. This flexibility saves time and money during installation.

3. Rugged Industrial Design:

The 6U Eurocard form factor and industrial-grade components enable 24/7 operation in harsh environments (e.g., power plant turbine halls). The board’s conformal coating protects against dust and moisture, extending its lifespan.

4. Easy Troubleshooting:

Diagnostic LEDs provide instant visual feedback on board status (e.g., power, communication, fault codes), reducing troubleshooting time from hours to minutes. For example, if a fault code is displayed, technicians can quickly reference the Mark V manual to identify and resolve the issue.

5. Cost-Effective Scalability:

Auxiliary board support allows facilities to expand functionality (e.g., adding LAN communication) without replacing the core board. This scalability is ideal for growing power plants that need to add more sensors or actuators.

DS200SDCCG1AEC

Typical Applications

The GE DS200SDCCG1AEC is widely used in industrial automation systems for:

-

Power Generation:

-

Controls gas/steam turbines in power plants, ensuring stable power output and efficient fuel use.

-

-

Manufacturing:

-

Drives motors for assembly line equipment (e.g., conveyor belts, robotic arms) in automotive and electronics manufacturing.

-

-

Petrochemical Industry:

-

Regulates pumps and compressors in refineries, ensuring safe and efficient operation in hazardous environments.

-