Description

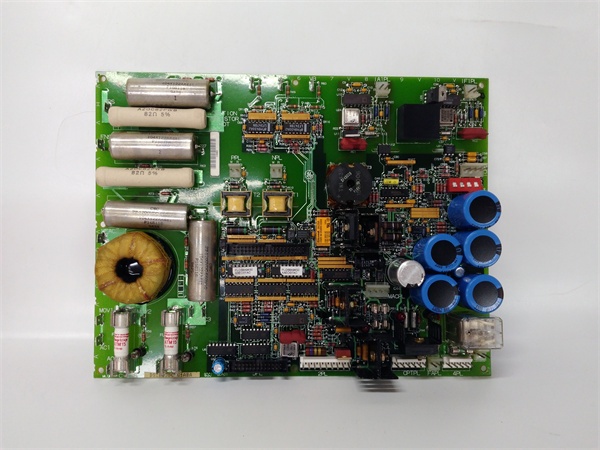

DS200SDCIG1A: Product Overview

The GE DS200SDCIG1A is a contact input group isolation terminal board designed specifically for GE Mark V gas and steam turbine control systems, a legacy platform renowned for its reliability in industrial power generation. As part of the Mark V ecosystem, it acts as a “signal gateway” for dry contact signals (e.g., from limit switches, pushbuttons, or safety interlocks), converting physical switch states into electrical signals that the turbine control unit can process. Its primary role is to ensure noise-immune signal transmission between field devices and the control system, which is critical for preventing false triggers or missed signals in high-stakes applications like turbine shutdown or fuel flow adjustment.

Role in Automation Systems:

Positioned as a “field signal interface” in Mark V architectures, the DS200SDCIG1A performs two primary functions:

-

Signal Acquisition: Receives dry contact signals from field devices (e.g., a switch indicating a turbine valve is open) and converts them into a format suitable for the VMEbus controller.

-

Signal Isolation: Uses group isolation to prevent electrical noise (e.g., from nearby motors or relays) from interfering with signal integrity, ensuring the turbine control unit receives accurate data.

Core Functionality:

-

VMEbus Compatibility: Conforms to VMEbus Rev. C.1 standards, ensuring seamless integration with existing Mark V I/O racks and controllers (e.g., GE Fanuc 90-30 series). This allows the board to work with legacy Mark V components without major system upgrades.

-

Flexible Signal Handling: Supports 24 dry contact inputs, grouped into isolated sections to minimize cross-talk between channels. This flexibility allows engineers to connect multiple field devices (e.g., switches, sensors) to a single board, reducing the need for additional wiring.

-

Noise Suppression: Integrated surge protection and high-frequency noise filters protect the board from electrical transients (e.g., lightning strikes or power surges) and electromagnetic interference (EMI) in harsh industrial environments.

-

Redundancy Support: Compatible with simplex (single-board operation) and TMR (triple-board redundancy) configurations, enhancing system reliability for mission-critical applications like turbine control.

Platform Benefits (Mark V Series):

The DS200SDCIG1A inherits the Mark V platform’s strengths, including:

-

Reliability: The Mark V system is the industry standard for gas turbine control, with a proven track record of 24/7 operation in power plants worldwide.

-

Legacy Compatibility: The board is designed to work with existing Mark V components (e.g., I/O modules, contactors), reducing the cost of system upgrades.

-

Scalability: Supports expansion with additional terminal boards to accommodate growing system demands (e.g., adding more switches or sensors to a turbine control system).

GE DS200SDCIG1A

Technical Specifications

-

Model Number: DS200SDCIG1A (Variant of Mark V Series)

-

Manufacturer: GE (General Electric)

-

Product Type: Contact Input Group Isolation Terminal Board

-

Series: Mark V (Gas/Steam Turbine Control)

-

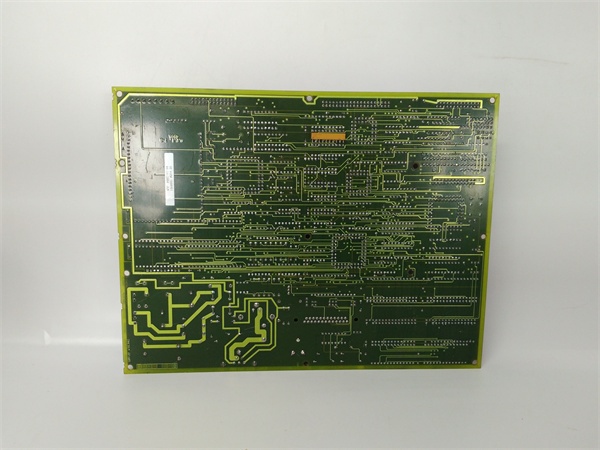

Form Factor: 6U Eurocard (160 mm × 233 mm, standard for Mark V devices)

-

Bus Standard: VMEbus Rev. C.1 (supports 8/16/32-bit data transfer)

-

Input Channels: 24 dry contact inputs (group-isolated, 1500 V AC channel-to-channel)

-

Input Voltage Range: 0–60 V DC (nominal 24 V DC)

-

Input Current: 4.2 mA per channel (typical)

-

Response Time: 1 ms ON / 1 ms OFF (ultra-fast for high-speed control)

-

Isolation: Galvanic isolation (optocouplers, 1500 V AC channel-to-channel)

-

Power Consumption: 80 mA @ 5 V DC (backplane), 125 mA @ 24 V DC (isolated)

-

Operating Temperature: 0°C to +55°C (industrial-grade)

-

Storage Temperature: -40°C to +85°C

-

Humidity: 5–95% non-condensing

-

Weight: ~0.32 kg (0.71 lbs)

-

Certifications: CE, UL (inferred from GE industrial product standards)

Core Features & Customer Value

1. Reliable Signal Acquisition:

The DS200SDCIG1A’s 24 dry contact inputs and group isolation ensure accurate signal detection, even in electrically noisy environments. For example, in a power plant, the board can reliably detect a turbine emergency stop switch activation and transmit the signal to the VMEbus controller, which triggers an immediate shutdown to prevent damage.

2. Flexible Configuration:

The 24-input design allows engineers to customize the board’s functionality for different field devices, reducing the need for additional wiring. This flexibility saves time and money during installation.

3. Rugged Industrial Design:

The board’s operating temperature range (0°C to +55°C) and compact form factor make it suitable for harsh industrial environments. Its DIN rail mounting option simplifies installation in crowded control cabinets.

4. Easy Troubleshooting:

The board includes status LEDs for power and communication, simplifying troubleshooting and reducing downtime. For example, if a sensor fails, the corresponding LED will turn off, allowing technicians to identify the problem quickly.

GE DS200SDCIG1A

Typical Applications

The GE DS200SDCIG1A is widely used in industrial automation systems for:

-

Power Generation:

-

Monitors dry contact signals from gas/steam turbines (e.g., valve position switches, emergency stop buttons) for real-time control.

-

-

Manufacturing:

-

Used in assembly lines to monitor the status of limit switches, proximity sensors, and other digital devices, enabling precise control of manufacturing processes.

-

-

Petrochemical Industry:

-

Controls dry contact signals from refinery equipment (e.g., pump start/stop commands, valve positions), ensuring safe and efficient operation in hazardous environments.

-