Description

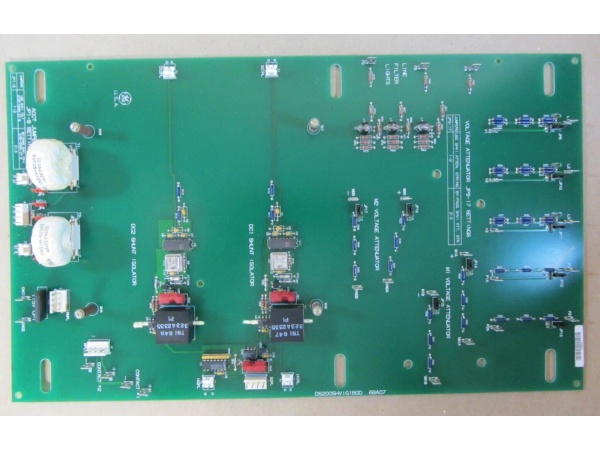

DS200SHVIG1B: Product Overview

The GE DS200SHVIG1B is an SCR high voltage interface board designed specifically for GE Speedtronic™ Mark V distributed control systems (DCS), the industry standard for gas, steam, and hydro turbine control in power generation. As part of the Mark V ecosystem, it serves as the “signal translator” between low-level voltage inputs (from field devices or upstream components) and the high-voltage power supplies of turbine drives. Its primary role is to convert and transmit voltage signals accurately, ensuring the drive’s power supply responds appropriately to control commands—critical for maintaining turbine stability and efficiency.

Engineered for the demanding conditions of turbine halls, the DS200SHVIG1B features a ruggedized metal construction and advanced signal processing circuitry to withstand vibration, dust, and electromagnetic interference (EMI). Its legacy compatibility makes it ideal for retrofitting aging Mark V systems—common in power plants operating turbines for 20+ years—where replacing the entire control architecture is cost-prohibitive. Whether used in 7EA gas turbines or 9F steam turbines, the DS200SHVIG1B ensures reliable signal conversion, directly extending the operational life of critical turbine control systems.

Role in Automation Systems

Positioned as a “high-voltage signal gateway” in Mark V architectures, the DS200SHVIG1B performs two primary functions:

-

Signal Conversion: Converts low-level differential voltage signals (-500 mV to 500 mV) from field devices (e.g., sensors, actuators) into high-frequency differential signals (0 to 500 kHz) that the drive’s power supply can interpret. This conversion is essential for translating physical measurements (e.g., turbine speed, fuel flow) into actionable control commands.

-

Fault Monitoring: Uses 17 configurable jumpers (protected by 10:1 current transformers) to adjust signal attenuation and prevent overvoltage damage. Three onboard LEDs provide real-time feedback on fuse status and signal integrity, enabling quick troubleshooting if faults occur.

Its core value lies in bridging the gap between low-level signals and high-voltage power supplies—a critical step in maintaining turbine stability, as even minor signal inaccuracies can lead to process instability (e.g., turbine speed variations) or equipment damage (e.g., excitation system failure).

Core Functionality

-

High-Precision Signal Conversion: The DS200SHVIG1B’s analog-to-frequency conversion circuitry ensures accurate translation of low-level voltage signals into high-frequency outputs. For example, a -250 mV input signal (representing a turbine speed deviation) is converted to a 250 kHz output, prompting the drive’s power supply to adjust fuel flow and correct the deviation.

-

Configurable Attenuation: The 17 onboard jumpers allow engineers to customize signal attenuation based on field device requirements. This flexibility reduces the need for additional signal conditioning hardware, saving time and money during installation.

-

Fault Protection: The 10:1 current transformers protect sensitive components from overvoltage transients, while the three LEDs (power, fault, fuse) provide instant visual feedback on board status. If a fuse blows (e.g., due to a short circuit), the corresponding LED illuminates, allowing technicians to quickly identify and resolve the issue.

-

Legacy Compatibility: The DS200SHVIG1B is fully compatible with existing Mark V components (e.g., power connect cards (PCCA), instrumentation cards), reducing the cost of system upgrades. This makes it an ideal choice for power plants with aging Mark V systems, where replacing the entire control architecture is not feasible.

DS200SHVIG1B

Technical Specifications

|

Parameter

|

Specification

|

|---|---|

|

Model Number

|

DS200SHVIG1B

|

|

Manufacturer

|

General Electric (GE)

|

|

Product Type

|

SCR High Voltage Interface Board

|

|

Series

|

Mark V (Turbine Control Systems)

|

|

Input Signal Range

|

-500 mV to 500 mV (differential)

|

|

Output Frequency Range

|

0 to 500 kHz (differential)

|

|

Configurable Jumpers

|

17 (for attenuation adjustment, protected by 10:1 current transformers)

|

|

Indicators

|

3 onboard LEDs (power, fault, fuse status)

|

|

Operating Temperature

|

-40°C to +70°C (industrial-grade)

|

|

Storage Temperature

|

-40°C to +85°C

|

|

Humidity

|

5–95% non-condensing

|

|

Weight

|

~0.14 kg (0.31 lbs)

|

|

Form Factor

|

Compact (11 x 6 x 6.7 cm)

|

|

Certifications

|

CE, UL (inferred from GE industrial product standards)

|

Core Features & Customer Value

1. Reliable Signal Conversion:

The DS200SHVIG1B’s high-precision signal conversion ensures that the drive’s power supply receives accurate commands, maintaining turbine stability. For example, in a power plant, the board can convert a turbine exhaust temperature signal (from a thermocouple) into a frequency that adjusts the fuel valve position, optimizing efficiency and reducing emissions.

2. Flexible Configuration:

The 17 configurable jumpers allow engineers to adapt the board to different field devices, reducing the need for additional hardware. This flexibility saves time and money during installation, especially in retrofit projects.

3. Fault Tolerance:

The onboard LEDs and current transformers provide critical fault protection, reducing the risk of damage to sensitive components. This is invaluable for power plants, where unplanned downtime can result in significant financial losses.

4. Legacy Compatibility:

Designed to work with existing Mark V components, the DS200SHVIG1B eliminates the need for costly system upgrades. This makes it an ideal choice for power plants with aging Mark V systems, where replacing the entire control architecture is not feasible.

DS200SHVIG1B

Typical Applications

The GE DS200SHVIG1B is widely used in industrial automation systems for:

-

Power Generation:

-

Converts low-level voltage signals from gas/steam turbines (e.g., speed, temperature, fuel flow) into high-frequency signals for the drive’s power supply, ensuring stable power output.

-

-

Industrial Drives:

-

Used in industrial motor drives (e.g., conveyor belts, pumps) to convert sensor signals into control commands for variable frequency drives (VFDs).

-

-

Retrofit Projects:

-

Ideal for retrofitting aging Mark V systems, where replacing the entire control architecture is cost-prohibitive. The board’s legacy compatibility allows for easy integration with existing components.

-