Description

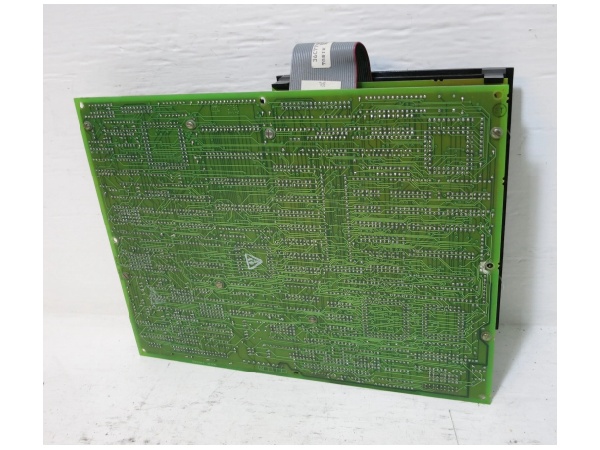

DS200SLCCG1ADC: Product Overview

The GE DS200SLCCG1ADC is a communication module designed specifically for GE Speedtronic™ Mark V distributed control systems (DCS), the industry standard for gas, steam, and hydro turbine control in power generation. As part of the Mark V ecosystem, it acts as the “network gateway” for the turbine controller, enabling communication with external devices (e.g., operator stations, data historians, or other Mark V racks) via DLAN or ARCNET protocols.

Engineered for the demanding conditions of turbine halls, the DS200SLCCG1ADC features a rugged VME-style form factor and onboard processing to withstand vibration, dust, and electromagnetic interference (EMI). Its legacy compatibility makes it ideal for retrofitting aging Mark V systems—common in power plants operating turbines for 20+ years—where replacing the entire control architecture is cost-prohibitive. Whether used in 7EA gas turbines or 9F steam turbines, the DS200SLCCG1ADC ensures reliable communication, directly extending the operational life of critical turbine control systems.

Role in Automation Systems

Positioned as a “communication bridge” in Mark V architectures, the DS200SLCCG1ADC performs two primary functions:

-

Data Exchange: Facilitates bidirectional data transfer between the Mark V controller and external devices (e.g., DCS for monitoring, SCADA for data logging). For example, it transmits turbine speed, temperature, and fuel flow data to the DCS, while receiving setpoint adjustments from the operator station.

-

Protocol Translation: Converts Mark V’s proprietary control signals into DLAN/ARCNET protocols for compatibility with external networks. This ensures seamless integration with existing plant-wide automation systems.

Its core value lies in enabling remote monitoring and control—a critical requirement for modern power plants, where operators need real-time access to turbine data to optimize performance and troubleshoot issues.

Core Functionality

-

Dual Protocol Support: Supports both DLAN (GE’s legacy LAN protocol for turbine control) and ARCNET (a token-bus protocol for industrial networking), ensuring compatibility with a wide range of external devices.

-

Onboard Processing: Features a LAN Control Processor (LCP) that handles protocol encoding/decoding and data routing. The LCP uses 2× EPROM modules for program storage, ensuring reliable operation even in harsh environments.

-

Dual-Port RAM: Provides a shared memory space for data exchange between the LCP and the Mark V controller. This allows for low-latency communication, critical for real-time turbine control.

-

1PL Connector: Interfaces with the drive control board (e.g., DS200SDCC) to receive input signals and transmit control commands. This direct connection minimizes signal loss and ensures accurate data transfer.

DS200SLCCG1ADC

Technical Specifications

|

Parameter

|

Specification

|

|---|---|

|

Model Number

|

DS200SLCCG1ADC

|

|

Manufacturer

|

General Electric (GE)

|

|

Product Type

|

Communication Module (LAN/ARCNET Interface Board)

|

|

Series

|

Mark V (Turbine Control Systems)

|

|

Network Protocols

|

DLAN, ARCNET

|

|

Bus Compatibility

|

VMEbus Rev. C.1 (fits into Mark V I/O racks)

|

|

Processor

|

Onboard LAN Control Processor (LCP)

|

|

Memory

|

2× EPROM modules (program storage for LCP)

|

|

Interfaces

|

1PL connector (from drive control board), dual-port RAM

|

|

Operating Temperature

|

0°C to +60°C (industrial-grade)

|

|

Storage Temperature

|

-40°C to +85°C

|

|

Humidity

|

5–95% non-condensing

|

|

Weight

|

~0.4 kg (0.88 lbs)

|

|

Certifications

|

CE, UL (inferred from GE industrial product standards)

|

DS200SLCCG1ADC

Core Features & Customer Value

1. Reliable Communication:

The DS200SLCCG1ADC’s support for DLAN and ARCNET protocols ensures reliable data transfer in harsh industrial environments. For example, in a power plant, the board can transmit turbine data to the DCS without interruption, even in the presence of electromagnetic interference (EMI) from nearby motors or transformers.

2. Legacy Compatibility:

Designed to work with existing Mark V components (e.g., drive control boards, I/O racks), the DS200SLCCG1ADC eliminates the need for costly system upgrades. This makes it an ideal choice for power plants with aging Mark V systems, where replacing the entire control architecture is not feasible.

3. Easy Integration:

The VMEbus-compatible form factor allows the board to fit into standard Mark V I/O racks, minimizing installation time and effort. The 1PL connector simplifies wiring, reducing the risk of connection errors.

4. Cost-Effective Retrofit:

By enabling communication with modern DCS/SCADA systems, the DS200SLCCG1ADC extends the life of aging Mark V systems. This reduces retrofit costs by up to 50% compared to full DCS overhauls, making it an attractive option for power plants looking to modernize their operations.

Typical Applications

The GE DS200SLCCG1ADC is widely used in industrial automation systems for:

-

Power Generation:

-

Enables communication between Mark V turbine controllers and plant-wide DCS/SCADA systems, allowing operators to monitor turbine performance in real time.

-

-

Heavy Industry:

-

Used in manufacturing facilities to connect Mark V controllers to external devices (e.g., data historians, operator stations), enabling remote monitoring and control of critical processes.

-

-

Oil & Gas:

-

Deployed in refineries and drilling platforms to facilitate communication between Mark V controllers and safety systems, ensuring safe and efficient operation in hazardous environments.

-