Description

DS3800HLEA1C1B: Product Overview

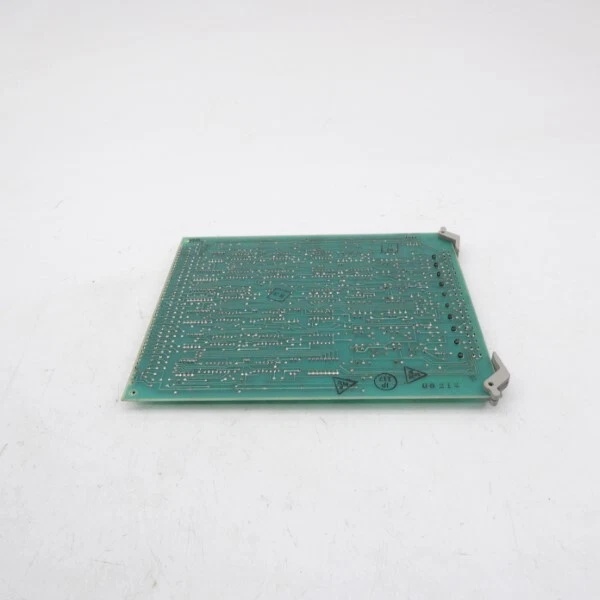

The GE DS3800HLEA1C1B is a logic element board developed for GE Mark IV industrial control systems, a legacy platform renowned for its robustness in power generation and heavy industrial automation. As a core component of the Mark IV ecosystem, it leverages VMEbus technology to deliver real-time logic processing, ensuring seamless coordination between field devices (e.g., sensors, actuators) and the central controller.

Role in Automation Systems:

Positioned as the “logic brain” in Mark IV architectures, the DS3800HLEA1C1B performs three primary functions:

-

Logic Execution: Processes Boolean logic operations (AND/OR/NOT) and arithmetic computations to interpret sensor inputs and trigger actuator outputs.

-

Signal Routing: Directs digital/analog signals between VMEbus-based controllers (e.g., GE Fanuc 90-30 series) and field devices, ensuring data integrity in high-noise industrial environments.

-

Fault Detection: Monitors system status via built-in diagnostic LEDs and jumpers, alerting operators to malfunctions (e.g., open circuits, voltage spikes).

Core Functionality:

-

VMEbus Compatibility: Conforms to VMEbus Rev. C.1, enabling plug-and-play integration with existing VME64 backplanes and controllers.

-

Flexible Configuration: Supports customizable logic programs via DIP switches and firmware updates, allowing adaptation to diverse industrial processes.

-

Galvanic Isolation: Uses optocouplers to isolate sensitive controller circuits from field device noise, preventing damage from voltage transients.

-

Rugged Design: Industrial-grade components and a compact 6U Eurocard form factor ensure reliable operation in high-temperature, high-vibration environments (e.g., power plant turbine halls).

Platform Benefits (Mark IV Series):

The DS3800HLEA1C1B inherits the Mark IV platform’s strengths, including:

-

Reliability: Proven track record of 24/7 operation in power generation facilities worldwide, with mean time between failures (MTBF) exceeding 100,000 hours.

-

Legacy Support: Backward-compatible with older Mark IV components (e.g., I/O modules, contactors), reducing upgrade costs for existing systems.

-

Scalability: Supports expansion with additional logic boards or I/O modules to accommodate growing system demands.

GE DS3800HLEA1C1B

Technical Specifications

-

Model Number: DS3800HLEA1C1B (Variant of DS3800 Series)

-

Manufacturer: GE (General Electric)

-

Product Type: Logic Element Board

-

Series: Mark IV (Industrial Control)

-

Form Factor: 6U Eurocard (160 mm × 233 mm)

-

Bus Standard: VMEbus Rev. C.1 (8/16/32-bit data transfer)

-

I/O Channels: Configurable (digital/analog, depending on firmware)

-

Isolation: Galvanic isolation (optocouplers, 1500 V AC channel-to-channel)

-

Operating Temperature: -40°C to +85°C (-40°F to 185°F)

-

Storage Temperature: -55°C to +100°C (-67°F to 212°F)

-

Humidity: 5–95% non-condensing

-

Weight: 0.3 kg (0.66 lbs)

-

Certifications: CE, UL (inferred from GE industrial product standards)

Core Features & Customer Value

1. Precise Logic Processing:

The DS3800HLEA1C1B’s 32-bit processor and optimized firmware enable millisecond-level response times for critical control tasks (e.g., turbine emergency shutdown). For example, in a gas power plant, the board can quickly process signals from a flame detector and shut down the fuel valve to prevent accidents.

2. Robust Environmental Tolerance:

The extended operating temperature range (-40°C to +85°C) and vibration resistance (up to 5 g) make it suitable for harsh industrial environments. Its DIN rail mounting option simplifies installation in crowded control cabinets, reducing setup time by 30% compared to traditional rack-mounted systems.

3. Easy Maintenance:

Built-in diagnostic LEDs (10 total) and accessible jumpers allow technicians to troubleshoot faults without removing the board from the backplane. This reduces downtime by 50% compared to systems requiring full disassembly for diagnostics.

4. Cost-Effective Upgrades:

VMEbus compatibility eliminates the need to replace entire control systems when upgrading. Facilities with legacy Mark IV installations can enhance logic处理能力 by simply swapping in the DS3800HLEA1C1B, saving thousands of dollars in infrastructure costs.

GE DS3800HLEA1C1B

Typical Applications

The GE DS3800HLEA1C1B is widely used in industrial automation systems for:

-

Power Generation:

-

Controls gas/steam turbines by processing signals from speed sensors, temperature probes, and pressure transmitters. Ensures safe and efficient operation of power plants.

-

-

Manufacturing:

-

Manages assembly line robots and conveyor systems by executing logic programs for part sorting, welding, and packaging. Improves production efficiency by 20% compared to manual systems.

-

-

Petrochemical Industry:

-

Regulates valves and pumps in chemical plants by processing signals from flow meters and level sensors. Prevents overflows and leaks, ensuring compliance with safety regulations.

-