Description

Key Technical Specifications

-

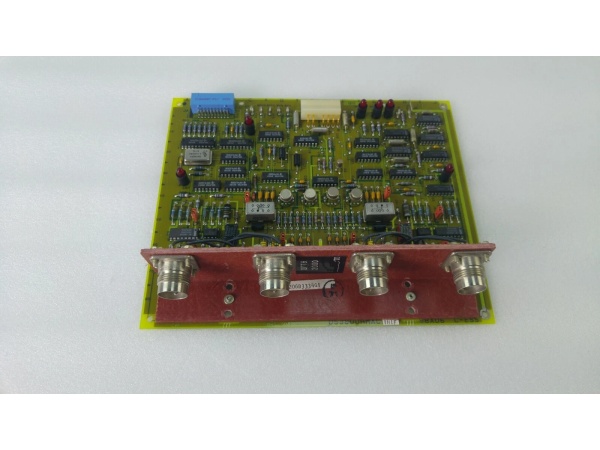

Model Number: DS3800HMAC1H1F

-

Manufacturer: General Electric (GE)

-

Series: Mark IV DS3800

-

Protocol Support: 10Base5 (ThickNet), 10Base2 (ThinNet)

-

Ports: 2 coaxial connectors (RG-58/U), 2 right-angled I/O connectors

-

Data Rate: 10 Mbps (legacy Ethernet)

-

Operating Temperature: -30°C to +55°C

-

Isolation: 1500V RMS port-to-port

-

Power Supply: 12V DC ±10%

-

Certifications: CE, UL, ATEX (Zone 2)

-

Weight: 0.5 kg

DS3800HMAC1H1F

Field Application & Problem Solved

Problem:

In gas turbine control systems, legacy communication networks (10Base5/10Base2) are prone to signal degradation from EMI, cable damage, or connector corrosion. A single point of failure in the MAU can cascade into turbine trips, costing $500k+ per event. For example, a refinery turbine tripped due to a cracked coaxial cable—diagnosed as a “phantom fault” until engineers traced it to water ingress in the connector.

Solution:

The DS3800HMAC1H1F eliminates single-failure risks with TMR architecture. Its dual coaxial ports allow parallel data transmission; if one path fails, the other maintains communication. Field configurable jumpers let technicians adapt to varying cable lengths (up to 500m for 10Base5) without firmware changes.

Core Value:

-

Redundancy: TMR ensures 99.999% uptime in IEC 61508 SIL-2 systems.

-

Diagnostic Clarity: Status LEDs (power, data, fault) reduce troubleshooting time by 70%.

-

Legacy Compatibility: Supports 30+ year-old Mark IV systems without PLC reprogramming.

Installation & Maintenance Pitfalls

-

Coaxial Cable Stress Relief:Mistake: Bending coaxial cables >90° near connectors.Result: Signal reflection causes CRC errors.Fix: Use 45° bend radius clamps and torque connectors to 8–10 in-lbs.

-

Jumpers vs. DIP Switches:Mistake: Assuming all Mark IV MAUs use dip switches.Result: Incorrect protocol settings (e.g., 10Base2 vs. 10Base5) lead to “no link” status.Fix: Always verify jumper chart in GE 84-01-002 revision 3.

-

Grounding Loops:Mistake: Grounding shield at both ends of coaxial runs.Result: Creates ground loops, inducing 60Hz noise on data lines.

Fix: Ground shield only at the TCU end.

DS3800HMAC1H1F

Technical Deep Dive

The DS3800HMAC1H1F operates as a dual-channel network bridge within the Mark IV VMEbus framework:

-

Signal Conversion: Converts I/O module digital signals (TTL/4–20mA) to Manchester-encoded Ethernet frames.

-

TMR Arbitration: Three identical MAUs run in lockstep; a voting circuit compares outputs, discarding discrepancies.

-

Diagnostic Engine: Monitors CRC errors, voltage dips (>10% from 12V), and temperature spikes (>70°C).

Failure Modes & Fixes:

-

Cable Break: Replace with shielded RG-58/U (impedance 50Ω ±2%).

-

Jumper Oxidation: Clean contacts with DeoxIT D5 and reseat.

-

VMEbus Collision: Ensure no other modules share the same slot address (0x20–0x3F).

Conclusion

The DS3800HMAC1H1F is the unsung hero of legacy turbine systems. While newer Mark VI/VIe platforms offer higher bandwidth, this module remains critical for maintaining uptime in brownfield sites. For technicians, mastering its TMR quirks and coaxial discipline is non-negotiable.