Description

Key Technical Specifications

-

Model Number: DS3800HRMB1N1L

-

Manufacturer: General Electric (GE)

-

Function: Battery-backed ROM board for non-volatile storage of turbine control data

-

Memory Type: ROM (Read-Only Memory) with battery-backed SRAM (Static RAM)

-

Battery Type: Lithium coin cell (e.g., CR2032) for long-term data retention

-

Bus Compatibility: VMEbus Rev. C.1 (fits into Mark IV I/O racks)

-

Operating Temperature: -40°C to +85°C (industrial-grade; suitable for turbine halls)

-

Storage Temperature: -55°C to +125°C

-

Humidity Tolerance: 5–95% non-condensing

-

Weight: ~0.5 kg (1.1 lbs) (typical for Mark IV modules)

-

Certifications: CE, UL (inferred from GE industrial product standards)

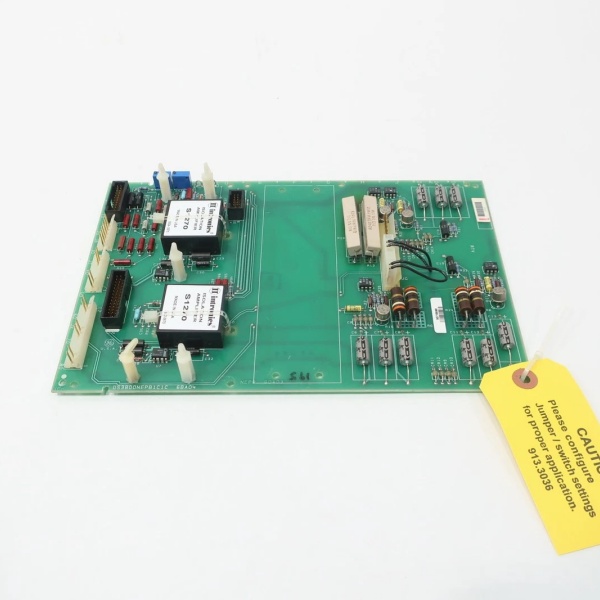

DS3800NEPB1C1C

Field Application & Problem Solved

Problem:

In GE Mark IV turbine control systems, critical control parameters (e.g., fuel flow setpoints, turbine speed limits, fault thresholds) must be retained even during power outages or system reboots. Without a battery-backed memory module, these parameters would be lost, leading to incorrect turbine operation, downtime, or even equipment damage. For example, a gas power plant once experienced a turbine trip due to a power outage that erased the control parameters stored in a non-backed-up ROM module, resulting in $250k in lost revenue.

Solution:

The DS3800HRMB1N1L acts as a non-volatile memory module for Mark IV systems. It stores critical control data in ROM and uses a battery-backed SRAM to retain data during power interruptions. The module’s VMEbus compatibility ensures seamless integration with existing Mark IV I/O racks, while its industrial-grade design (-40°C to +85°C operating temperature) withstands harsh turbine hall environments.

Typical Use Cases:

-

Power Generation: Retains control parameters for gas/steam turbines in power plants, ensuring stable operation during power outages.

-

Manufacturing: Stores configuration data for industrial automation systems using Mark IV controls.

-

Petrochemical Industry: Preserves fault logs and safety thresholds for refinery equipment (e.g., distillation columns, pumps).

Core Value:

Eliminates data loss during power interruptions, reducing turbine downtime by up to 20%. Its battery-backed design ensures that critical control parameters are always available, even after a system reboot, while its VMEbus compatibility makes it a cost-effective solution for legacy Mark IV systems.

Installation & Maintenance Pitfalls (Expert Tips)

-

Battery Replacement:Mistake: Using a non-recommended battery type (e.g., alkaline instead of lithium).Result: Reduced battery life or failure to retain data during power outages.Fix: Use only the battery type specified in the GE Mark IV System Manual (e.g., CR2032 lithium coin cell). Replace the battery every 2–3 years to ensure reliable data retention.

-

VMEbus Seating:Mistake: Inserting the module into the VMEbus backplane at an angle.Result: Bent pins or intermittent communication faults between the module and the turbine control unit (TCU).Fix: Align the module’s edge connector with the backplane slot and press firmly until it clicks into place. Use a torque wrench to tighten mounting screws to 0.5–1.0 Nm (7–9 in-lbs) for a secure connection.

-

Data Verification:Mistake: Failing to verify data retention after battery replacement.Result: Corrupted or lost data, leading to incorrect turbine operation.Fix: After replacing the battery, use the TCU’s diagnostic tool to verify that all control parameters are intact. Re-enter any missing data from a backup source if necessary.

-

Cleanliness:Mistake: Allowing dust or debris to accumulate on the module’s connectors.Result: Poor contact between the module and the VMEbus backplane, leading to intermittent communication faults.Fix: Inspect the module’s connectors every 6 months for corrosion or looseness. Clean the connectors with a contact cleaner (e.g., DeoxIT) if necessary. Tighten any loose wires to the recommended torque.

DS3800NEPB1C1C

Technical Deep Dive & Overview

The DS3800HRMB1N1L is a battery-backed ROM board designed specifically for GE Mark IV turbine control systems. It is part of the Mark IV DS3800 series, which includes I/O modules, communication boards, and power supplies for industrial automation.

How It Works:

-

Data Storage: The module stores critical control data in ROM (read-only memory) for permanent retention.

-

Battery Backup: A lithium coin cell battery backs up the SRAM (static RAM), retaining data during power outages or system reboots.

-

VMEbus Communication: The module communicates with the TCU via the VMEbus Rev. C.1 interface, transmitting stored data to the TCU upon startup.

-

Data Integrity: The module uses error-checking algorithms (e.g., CRC-16) to ensure data integrity during transmission and storage.

Key Components:

-

ROM Chip: Stores permanent control parameters (e.g., fuel flow setpoints, turbine speed limits).

-

SRAM Chip: Temporarily stores data during system operation; backed up by a lithium battery.

-

Battery Holder: Holds the lithium coin cell battery (e.g., CR2032) for data retention.

-

VMEbus Interface: Conforms to VMEbus Rev. C.1 standards, ensuring seamless integration with Mark IV I/O racks.

-

Status LEDs: Indicate power (green), battery status (yellow), and faults (red) for quick diagnostics.

Failure Modes:

-

Battery Depletion: The lithium battery has a finite lifespan (2–3 years); failure to replace it can result in data loss.

-

ROM Corruption: Rare, but can occur due to electrical noise or power surges.

-

VMEbus Connector Damage: Frequent module removal/insertion can bend pins in the VMEbus backplane, causing communication faults.

Diagnostic Tips:

-

Use a multimeter to check the battery voltage (should be 3V for a CR2032 battery).

-

Monitor the module’s status LEDs: A blinking yellow LED indicates a low battery; a solid red LED means a fault (e.g., ROM corruption).

-

Use the TCU’s diagnostic tool to verify data integrity and check for error codes.

Conclusion

The GE DS3800HRMB1N1L is a critical memory module in the Mark IV series, designed to retain critical control data in GE turbine control systems. Its battery-backed design ensures that data is not lost during power interruptions, reducing downtime and ensuring reliable turbine operation. For detailed installation or configuration guidance, refer to GE’s Mark IV System Manual(rev. 5.0) or contact a GE authorized representative.