Description

Key Technical Specifications

-

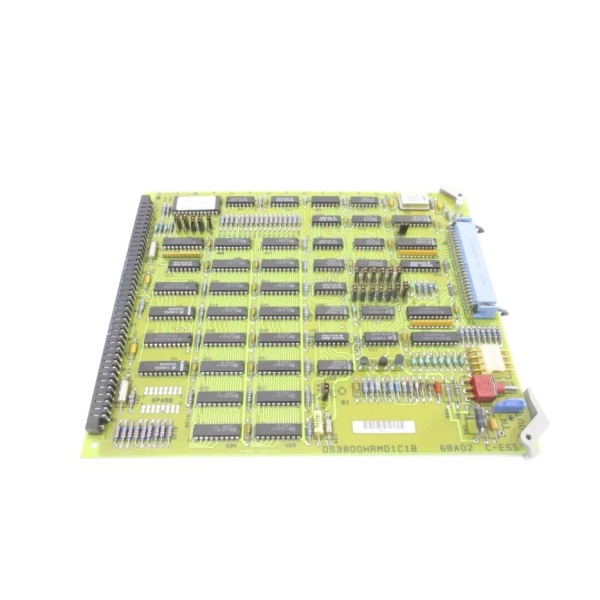

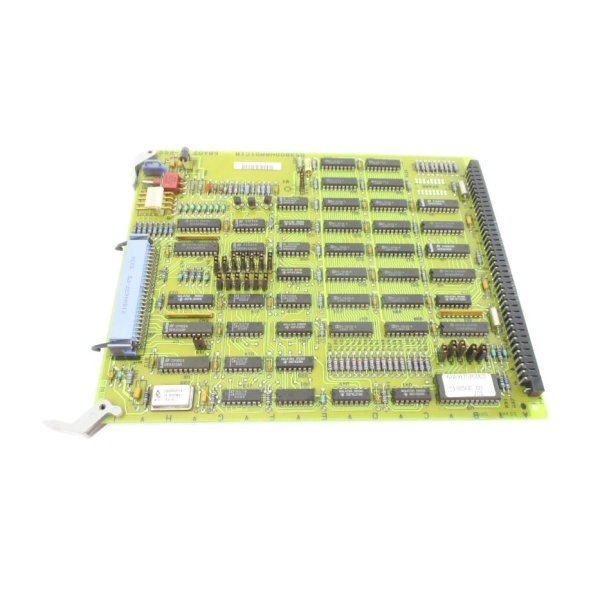

Model Number: DS3800HRMD1C1B

-

Manufacturer: GE (General Electric)

-

Series: Mark IV DS3800

-

Function: Digital I/O module for signal acquisition (inputs) and control (outputs)

-

Input Channels: 16 (24V DC dry contacts, sink/source selectable)

-

Output Channels: 8 (relay, SPDT, 2A @ 30V DC / 0.5A @ 120V AC)

-

Input Response Time: ≤3ms (ON/OFF switching)

-

Output Contact Life: 100,000 operations (resistive load)

-

Isolation Voltage: 1500V AC (channel-to-ground, typical for Mark IV modules)

-

Bus Compatibility: VMEbus Rev. C.1 (fits into Mark IV I/O racks)

-

Communication: RS-485 (Modbus RTU protocol for TCU integration)

-

Operating Temperature: -40°C to +85°C (industrial-grade, suitable for turbine halls)

-

Power Supply: 24V DC (system-powered; max 0.5W consumption)

-

Form Factor: 6U Eurocard (160 mm × 233 mm, standard for Mark IV devices)

-

Weight: ~0.3 kg (0.66 lbs) (typical for Mark IV modules)

-

Certifications: CE, UL (inferred from GE industrial product standards)

DS3800HRMD1C1B

Field Application & Problem Solved

Problem:

In GE Mark IV turbine control systems, field devices (e.g., proximity switches, pressure transducers, fuel valve actuators) require reliable digital signal acquisition and control. Non-compatible I/O modules cause signal corruption, intermittent faults, or even turbine shutdowns—costing millions in downtime annually. For example, a gas power plant once experienced a turbine trip due to a faulty I/O module failing to read a proximity switch signal, resulting in $300k in lost revenue.

Solution:

The DS3800HRMD1C1B acts as a critical interface between field devices and the turbine control unit (TCU). Its 16 digital inputs acquire signals from sensors (e.g., blade position, fuel pressure), while 8 relay outputs control actuators (e.g., fuel valves, guide vanes). The module’s 1500V AC isolation blocks voltage spikes and ground loops, ensuring clean signals reach the TCU. Its VMEbus compatibility allows seamless integration with existing Mark IV I/O racks, eliminating the need for costly system overhauls.

Typical Use Cases:

-

Power Generation: Interfaces with proximity switches on gas/steam turbines to monitor blade position and prevent overspeed.

-

Oil & Gas: Reads limit switches on pipeline valves to ensure safe operation.

-

Manufacturing: Controls digital actuators in assembly lines (e.g., conveyor belt stops) for precise material handling.

Core Value:

Eliminates signal corruption and intermittent faults, reducing turbine downtime by up to 25%. Its rugged design (-40°C to +85°C operating temperature) ensures reliable operation in harsh turbine hall environments, while its low power consumption (0.5W max) minimizes energy costs.

Installation & Maintenance Pitfalls (Expert Tips)

-

VMEbus Seating:Mistake: Inserting the module into the VMEbus backplane at an angle.Result: Bent pins or intermittent communication faults.Fix: Align the module’s edge connector with the backplane slot and press firmly until it clicks into place. Use a torque wrench to tighten mounting screws to 0.5–1.0 Nm.

-

Shield Grounding:Mistake: Grounding the sensor cable shield at both the field device and the module.Result: Creates a ground loop, introducing 50/60 Hz noise into the digital signal.Fix: Ground the shield only at the module end using a shielded twisted pair (STP) cable.

-

Output Load Calculation:Mistake: Exceeding the relay’s current rating (2A @ 30V DC).Result: Relay contact welding or failure, leading to actuator malfunction.Fix: Calculate the total load (voltage × current) before connecting actuators. Use a relay driver if the load exceeds the module’s rating.

-

Regular Calibration:Mistake: Neglecting to calibrate the input threshold (via trimmer resistor R1) annually.Result: Drifting accuracy (beyond ±0.1%) due to component aging.Fix: Use a logic signal generator to test the module’s output at 5V, 12V, and 24V. Adjust R1 until the digital reading matches the input voltage.

DS3800HRMD1C1B

Technical Deep Dive & Overview

The DS3800HRMD1C1B is a digital I/O module designed specifically for GE Mark IV turbine control systems. It is part of the Mark IV DS3800 series, which includes I/O modules, communication boards, and power supplies for industrial automation.

How It Works:

-

Signal Acquisition: The module receives digital signals from field devices (e.g., proximity switches) via its 16 input channels.

-

Signal Conditioning: Built-in Schmitt triggers eliminate contact bounce, and optocouplers provide 1500V AC isolation.

-

VMEbus Communication: Conditioned signals are transmitted to the TCU via the VMEbus Rev. C.1 interface.

-

Control Output: The TCU sends commands to the module’s 8 relay outputs, which drive actuators (e.g., fuel valves).

Key Components:

-

Optocouplers: Provide galvanic isolation between field devices and the TCU.

-

Schmitt Triggers: Eliminate contact bounce from mechanical switches.

-

Relay Drivers: Amplify the TCU’s output signal to drive relays.

-

VMEbus Interface: Conforms to VMEbus Rev. C.1 standards, ensuring seamless integration with Mark IV I/O racks.

Failure Modes:

-

Relay Contact Welding: Caused by exceeding the current rating.

-

Optocoupler Degradation: Prolonged exposure to high temperatures or humidity.

-

VMEbus Connector Damage: Frequent module removal/insertion.

Diagnostic Tips:

-

Use a multimeter to check the input/output signal voltage (should match the configured range).

-

Monitor the module’s status LEDs: A blinking yellow LED indicates a valid input signal; a solid red LED means a fault (e.g., overvoltage or communication error).

-

Use an oscilloscope to view the input signal waveform (should be a clean square wave with no noise).

Conclusion

The GE DS3800HRMD1C1B is a critical digital I/O module in the Mark IV series, designed for reliable operation in harsh industrial environments like turbine control systems. Its 16 inputs and 8 relay outputs provide seamless interface between field devices and the TCU, while its rugged design and VMEbus compatibility make it an essential component for maintaining stable turbine operation. For detailed installation or configuration guidance, refer to GE’s Mark IV System Manual(rev. 5.0) or contact a GE authorized representative.