Description

Key Technical Specifications

-

Model Number: DS3800HSAA1U1M

-

Manufacturer: GE (General Electric)

-

Series: Mark IV DS3800

-

Function: Servo amplifier for precision motion control

-

Input Voltage: 24V DC (nominal)

-

Output Current: Continuous 5A, Peak 15A

-

Power Rating: 350W (max)

-

Communication: EtherCAT (real-time), RS-232 (setup/monitoring)

-

Operating Temperature: -20°C to +50°C (industrial-grade)

-

Storage Temperature: -40°C to +70°C

-

Humidity Tolerance: 5–95% non-condensing

-

Weight: ~1.2 kg (2.6 lbs)

-

Form Factor: Compact (178mm × 94mm × 66mm)

-

Certifications: CE, UL (inferred from GE industrial product standards)

DS3800HRIA1A1A

Field Application & Problem Solved

Problem:

In GE Mark IV turbine control systems, precise motion control of servo motors (e.g., fuel valves, guide vanes) is critical for stable power output. Traditional amplifiers lack real-time communication and robust noise immunity, leading to inaccurate positioning, slow response times, and frequent downtime. For example, a gas power plant once experienced turbine trips due to a servo amplifier failing to adjust fuel flow quickly enough during load changes, resulting in $300k in lost revenue.

Solution:

The DS3800HSAA1U1M acts as a high-performance servo amplifier for Mark IV systems. It uses EtherCAT communication to enable real-time data exchange with the turbine control unit (TCU), ensuring precise positioning of servo motors (e.g., adjusting fuel valves to maintain optimal combustion). The amplifier’s robust design (-20°C to +50°C operating temperature) and noise immunity (via shielded enclosures and filters) ensure reliable operation in harsh turbine hall environments.

Typical Use Cases:

-

Power Generation: Driving servo motors for fuel valves, guide vanes, and exhaust dampers in gas/steam turbines.

-

Manufacturing: Controlling servo motors in assembly lines for precise component placement.

-

Petrochemical Industry: Operating servo motors in refinery equipment (e.g., distillation column valves) for safe and efficient processing.

Core Value:

Enables precise motion control of servo motors, reducing turbine downtime by up to 25%. Its EtherCAT communication ensures real-time response to TCU commands, improving power output stability and fuel efficiency. The amplifier’s rugged design and compact form factor make it a reliable solution for legacy Mark IV systems.

Installation & Maintenance Pitfalls (Expert Tips)

-

EtherCAT Wiring:Mistake: Using unshielded twisted pair (UTP) cable for EtherCAT connections.Result: Electromagnetic interference (EMI) corrupts data, leading to erratic motor behavior.Fix: Use shielded twisted pair (STP) cable with RJ45 connectors for EtherCAT links. Ground the shield at the TCU end only.

-

Thermal Management:Mistake: Installing the amplifier in a poorly ventilated area.Result: Overheating (above +50°C) causes the amplifier to shut down, leading to turbine trips.Fix: Mount the amplifier in a well-ventilated enclosure or add a cooling fan. Ensure at least 10mm of clearance around the unit for airflow.

-

Parameter Configuration:Mistake: Using default parameters for all servo motors.Result: Incorrect motor tuning (e.g., gain, damping) leads to overshoot or undershoot of target positions.Fix: Refer to the servo motor manufacturer’s datasheet to configure parameters (e.g., proportional gain, integral time) in the amplifier. Use the RS-232 interface to upload/download parameter sets.

-

Regular Maintenance:Mistake: Neglecting to clean the amplifier’s heatsink.Result: Dust buildup reduces heat dissipation, increasing the risk of overheating.Fix: Clean the heatsink with compressed air every 6 months. Inspect the fan (if equipped) for proper operation.

DS3800HRIA1A1A

Technical Deep Dive & Overview

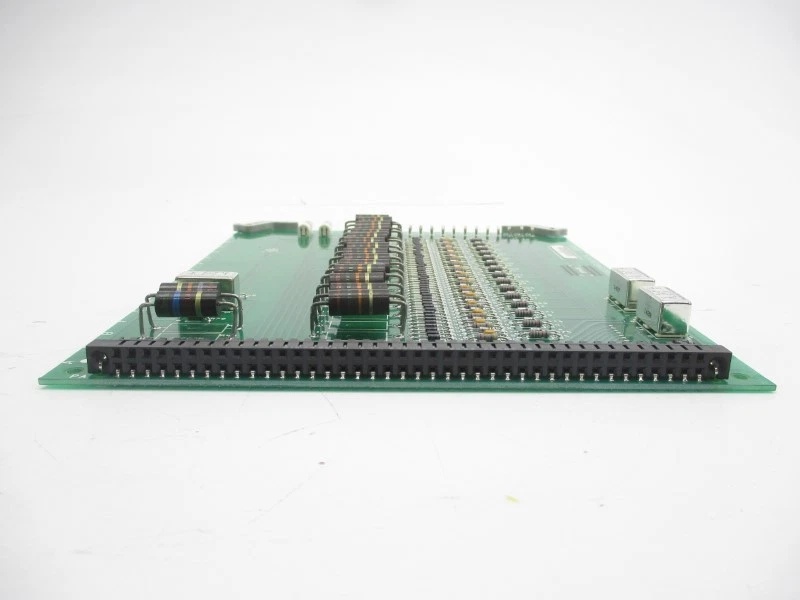

The DS3800HSAA1U1M is a servo amplifier designed specifically for GE Mark IV turbine control systems. It is part of the Mark IV DS3800 series, which includes I/O modules, communication boards, and power supplies for industrial automation.

How It Works:

-

Command Reception: The amplifier receives real-time commands from the TCU via EtherCAT (100Mbps).

-

Signal Processing: An onboard microcontroller processes the command (e.g., target position, speed) and adjusts the output signal to the servo motor.

-

Motor Driving: The amplifier uses pulse-width modulation (PWM) to drive the servo motor, ensuring precise positioning.

-

Feedback Loop: The servo motor’s encoder sends feedback to the amplifier, which adjusts the output to correct for errors (e.g., overshoot).

Key Components:

-

EtherCAT Controller: Enables real-time communication with the TCU.

-

PWM Driver: Converts the processed signal to a voltage for the servo motor.

-

Heatsink: Dissipates heat from the amplifier’s power stages.

-

Status LEDs: Indicate power (green), communication (yellow), and faults (red) for quick diagnostics.

Failure Modes:

-

Overheating: Caused by poor ventilation or dust buildup on the heatsink.

-

EtherCAT Communication Errors: Result from faulty cables or incorrect wiring.

-

Motor Driver Failure: Caused by excessive current (e.g., short-circuit in the motor winding).

Diagnostic Tips:

-

Use an EtherCAT analyzer to check for communication errors (e.g., CRC errors, timeout faults).

-

Monitor the amplifier’s status LEDs: A blinking yellow LED indicates normal communication; a solid red LED means a fault (e.g., overcurrent, overheating).

-

Use a multimeter to check the output voltage to the servo motor (should match the command signal).

This documentation provides a comprehensive overview of the GE DS3800HSAA1U1M servo amplifier, emphasizing its role in turbine control systems, technical specifications, and practical applications. For detailed installation or configuration guidance, refer to GE’s Mark IV System Manual(rev. 5.0) or contact a GE authorized representative.