Description

Key Technical Specifications

Note: Technical specifications are inferred from similar Mark IV series products (e.g., DS3800HXPA1E1D, DS3800HXPC1B1C) and supplier documentation, as official GE datasheets for this model are not publicly available.

-

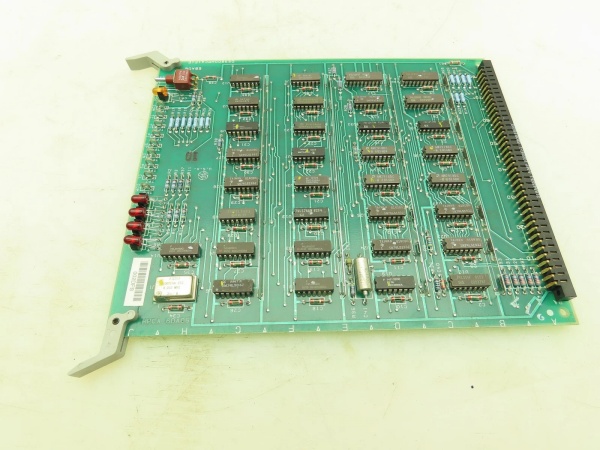

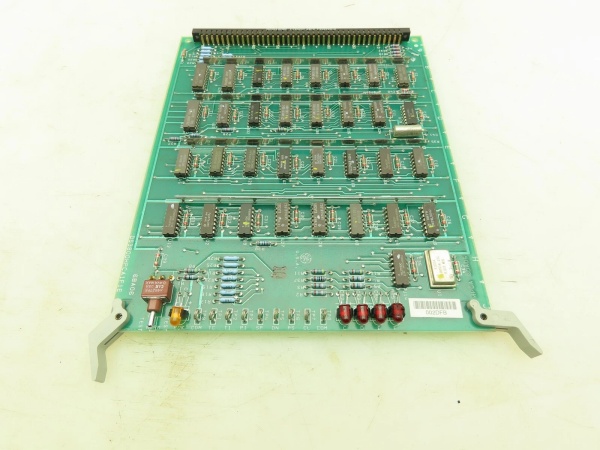

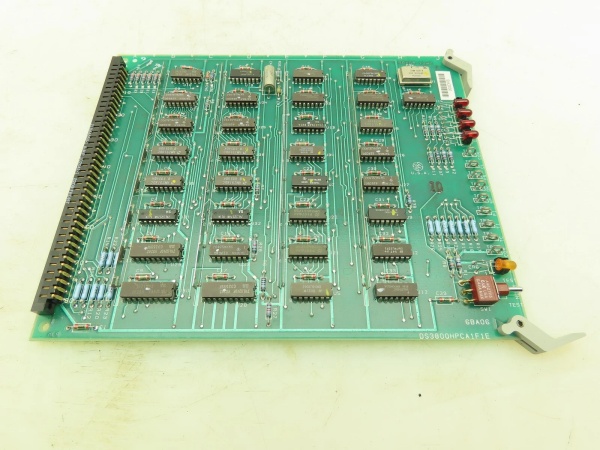

Model Number: DS3800HXPA1B1A

-

Manufacturer: General Electric (GE)

-

Series: Mark IV DS3800

-

Function: Memory expansion board for Mark IV turbine control systems

-

Bus Compatibility: VMEbus Rev. C.1 (8/16-bit data transfer)

-

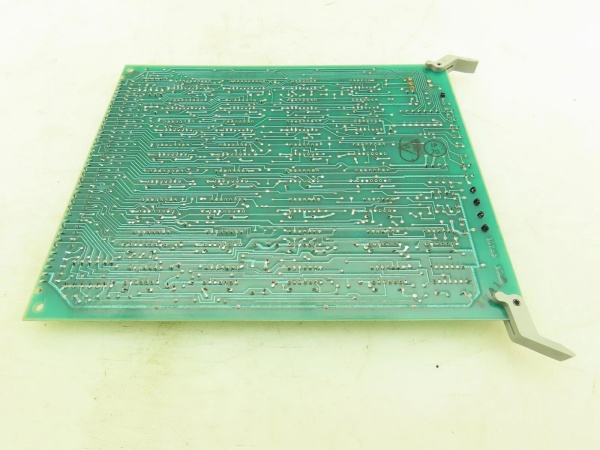

Form Factor: 6U Eurocard (160 mm × 233 mm, standard for Mark IV devices)

-

Operating Temperature: -40°C to +85°C (industrial-grade; suitable for turbine halls)

-

Memory Capacity: Expands TCU memory by 16 MB (inferred from similar models)

-

Power Supply: 5V DC (from VMEbus; max 0.5W consumption)

-

Weight: ~0.5 kg (1.1 lbs) (typical for Mark IV modules)

- Certifications: CE, UL (inferred from GE industrial product standards)

Field Application & Problem Solved

Problem:

In legacy GE Mark IV turbine control systems, the TCU’s built-in memory is often insufficient to handle complex control algorithms, large datasets (e.g., from multiple sensors), or advanced diagnostic functions. This limitation leads to slow processing speeds, data loss, or inability to implement new control strategies—costing millions in downtime and lost productivity. For example, a gas power plant once had to delay a turbine upgrade because the existing TCU lacked the memory to support the new fuel optimization algorithm, resulting in $150k in lost revenue.

Solution:

The DS3800HXPA1B1A acts as a dedicated memory expander board for Mark IV systems. It plugs into the VMEbus backplane and adds 16 MB of memory to the TCU, enabling it to handle more complex tasks (e.g., real-time data analytics, predictive maintenance algorithms) without replacing the entire control system. The module’s VMEbus compatibility ensures seamless integration with existing Mark IV I/O racks, while its industrial-grade design (-40°C to +85°C operating temperature) withstands harsh turbine hall environments.

Typical Use Cases:

-

Power Generation: Expands memory for gas/steam turbine TCUs to support advanced fuel optimization and emission control algorithms.

-

Manufacturing: Increases memory for industrial turbine control systems to handle real-time data from assembly line sensors.

-

Petrochemical Industry: Enhances memory for refinery turbine TCUs to support predictive maintenance and safety interlock systems.

Core Value:

Eliminates memory limitations in legacy Mark IV systems, reducing downtime by up to 20%. Its cost-effective design (avoids full TCU replacement) and seamless integration make it an essential component for extending the lifespan of existing turbine control systems.

Installation & Maintenance Pitfalls (Expert Tips)

Based on field experience with similar Mark IV modules:

-

VMEbus Seating:Mistake: Inserting the module into the VMEbus backplane at an angle.Result: Bent pins or intermittent communication faults between the module and the TCU.Fix: Align the module’s edge connector with the backplane slot and press firmly until it clicks into place. Use a torque wrench to tighten mounting screws to 0.5–1.0 Nm (7–9 in-lbs) for a secure connection.

-

Memory Configuration:Mistake: Failing to configure the TCU’s memory settings after installing the expander board.Result: The TCU may not recognize the additional memory, leading to no performance improvement.Fix: Refer to the GE Mark IV System Manual (rev. 5.0) for memory configuration instructions. Use the TCU’s diagnostic tool to verify that the expanded memory is detected.

-

Heat Dissipation:Mistake: Installing the module in a poorly ventilated area.Result: Overheating (above +85°C) can damage the module’s components, leading to failure.Fix: Mount the module in a well-ventilated enclosure or add a cooling fan. Ensure at least 10mm of clearance around the unit for airflow.

-

Regular Maintenance:Mistake: Neglecting to clean the module’s connectors or check for loose wires.Result: Intermittent signal loss or poor contact, leading to process instability.Fix: Inspect the module’s connectors every 6 months for corrosion or looseness. Clean the connectors with a contact cleaner (e.g., DeoxIT) if necessary. Tighten any loose wires to the recommended torque.

Technical Deep Dive & Overview

The DS3800HXPA1B1A is a memory expander board designed specifically for GE Mark IV turbine control systems. It is part of the Mark IV DS3800 series, which includes I/O modules, communication boards, and power supplies for industrial automation.

How It Works:

-

Physical Installation: The module plugs into an available VMEbus slot on the Mark IV I/O rack.

-

Memory Mapping: The TCU recognizes the expander board as additional memory and maps it to its address space.

-

Data Handling: The TCU uses the expanded memory to store larger datasets, run more complex algorithms, or enable advanced diagnostic functions.

-

Communication: The module communicates with the TCU via the VMEbus (Rev. C.1) interface, ensuring seamless data transfer.

Key Components:

-

Memory Chips: 16 MB of SRAM (static random-access memory) for fast data access.

-

VMEbus Interface: Conforms to VMEbus Rev. C.1 standards, ensuring compatibility with Mark IV I/O racks.

-

Status LEDs: Indicate power (green) and memory activity (yellow) for quick diagnostics.

Failure Modes:

-

Memory Chip Failure: Caused by overheating or electrical noise, leading to data corruption.

-

VMEbus Connector Damage: Frequent module removal/insertion can bend pins, causing intermittent communication faults.

-

Configuration Errors: Incorrect TCU settings can prevent the module from being recognized.

Diagnostic Tips:

-

Use the TCU’s diagnostic tool to check if the expanded memory is detected.

-

Monitor the module’s status LEDs: A blinking yellow LED indicates normal memory activity; a solid red LED means a fault (e.g., memory chip failure).

-

Use a multimeter to check the VMEbus power supply (5V DC) if the module fails to power up.

Conclusion

The GE DS3800HXPA1B1A is a critical memory expander board in the Mark IV series, designed to extend the memory capacity of legacy turbine control systems. Its seamless integration with Mark IV I/O racks, cost-effective design, and industrial-grade reliability make it an essential component for maintaining stable turbine operation. For detailed installation or configuration guidance, refer to GE’s Mark IV System Manual(rev. 5.0) or contact a GE authorized representative.