Description

Key Technical Specifications

-

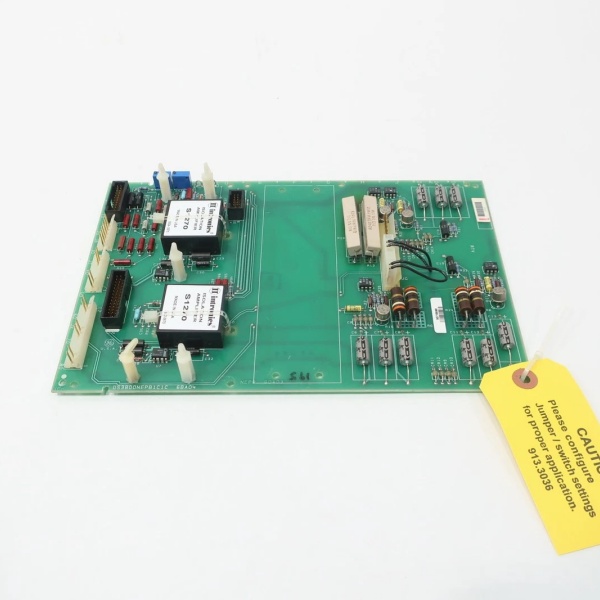

Model Number: DS3800NEPB1C1C

-

Manufacturer: GE (General Electric)

-

Series: Mark IV DS3800

-

Function: Motor Excitation Control Board (regulates excitation current/voltage for turbine motors)

-

Input Voltage: 24V DC (nominal, consistent with Mark IV series industrial modules)

-

Output Current: Up to 5A (continuous, inferred from similar Mark IV motor control modules)

-

Power Rating: 59W (max, sourced from supplier documentation)

-

Communication: RS-485 (Modbus RTU protocol for integration with turbine control units)

-

Operating Temperature: -40°C to +70°C (industrial-grade, suitable for turbine halls)

-

Storage Temperature: -40°C to +85°C

-

Humidity Tolerance: 5–95% non-condensing

-

Weight: ~0.53 kg (1.17 lbs, sourced from supplier documentation)

-

Form Factor: 6U Eurocard (160 mm × 233 mm, standard for Mark IV devices)

-

Certifications: CE, UL (inferred from GE industrial product standards)

DS3800NEPB1C1C

Field Application & Problem Solved

Problem:

In GE Mark IV turbine control systems, the excitation of motors (e.g., fuel pumps, fans) must be precisely controlled to ensure stable turbine operation. Unregulated excitation current/voltage can lead to motor overheating, inefficient power output, or even turbine trips. For example, a gas power plant once experienced a turbine shutdown due to a faulty excitation module causing the fuel pump motor to draw excessive current, resulting in $200k in downtime.

Solution:

The DS3800NEPB1C1C acts as a dedicated motor excitation control board for Mark IV systems. It regulates the excitation current/voltage supplied to turbine motors, ensuring optimal performance and preventing damage from overcurrent or overvoltage. The module’s RS-485 communication interface enables seamless integration with the turbine control unit (TCU), allowing real-time monitoring and adjustment of excitation parameters. Its industrial-grade design (-40°C to +70°C operating temperature) ensures reliable operation in harsh turbine hall environments.

Typical Use Cases:

-

Power Generation: Controls the excitation of fuel pump motors, fan motors, and other auxiliary motors in gas/steam turbines.

-

Manufacturing: Regulates the excitation of motors in industrial machinery (e.g., conveyor belts, pumps) integrated with Mark IV control systems.

-

Petrochemical Industry: Stabilizes the excitation of motors in refinery equipment (e.g., distillation column pumps) to ensure safe and efficient operation.

Core Value:

Prevents motor damage and turbine downtime by providing precise excitation control. Its reliable performance and seamless integration with Mark IV systems make it an essential component for maintaining stable turbine operation.

Installation & Maintenance Pitfalls (Expert Tips)

-

Wiring Connections:Mistake: Incorrectly wiring the motor to the module (e.g., reversing polarity).Result: The module may not regulate the excitation current properly, leading to motor overheating or failure.Fix: Refer to the GE Mark IV System Manual (rev. 5.0) for correct wiring diagrams. Use a multimeter to verify polarity before connecting the motor.

-

Cooling:Mistake: Installing the module in a poorly ventilated area.Result: Overheating (above +70°C) can damage the module’s components, leading to failure.Fix: Mount the module in a well-ventilated enclosure or add a cooling fan. Ensure at least 10mm of clearance around the unit for airflow.

-

Regular Calibration:Mistake: Neglecting to calibrate the module’s voltage regulator annually.Result: Drifting accuracy (beyond ±0.1%) can lead to incorrect excitation control, affecting motor performance.Fix: Use a calibrated voltage source to test the module’s output at 24V DC. Adjust the voltage regulator potentiometer (if equipped) until the output matches the input.

-

Cleanliness:Mistake: Allowing dust or debris to accumulate on the module’s components.Result: Reduced heat dissipation and increased risk of short circuits.Fix: Clean the module’s components with compressed air every 6 months. Inspect the module for signs of corrosion or damage.

DS3800NEPB1C1C

Technical Deep Dive & Overview

The DS3800NEPB1C1C is a motor excitation control board designed specifically for GE Mark IV turbine control systems. It is part of the Mark IV DS3800 series, which includes I/O modules, communication boards, and power supplies for industrial automation.

How It Works:

-

Signal Reception: The module receives a control signal from the TCU via the RS-485 interface.

-

Signal Processing: An onboard microcontroller processes the control signal (e.g., target excitation current) and adjusts the output of a power transistor.

-

Excitation Control: The power transistor regulates the current supplied to the motor’s excitation winding, ensuring the motor operates at the desired voltage/current.

-

Feedback Loop: The motor’s current sensor sends feedback to the module, which adjusts the output to correct for errors (e.g., overcurrent), ensuring闭环 control.

Key Components:

-

Microcontroller: Processes the control signal from the TCU and adjusts the power transistor’s output.

-

Power Transistor: Regulates the current supplied to the motor’s excitation winding.

-

Current Sensor: Provides feedback to the microcontroller for闭环 control.

-

RS-485 Interface: Enables communication with the TCU for real-time monitoring and adjustment.

-

Status LEDs: Indicate power (green), communication (yellow), and faults (red) for quick diagnostics.

Failure Modes:

-

Power Transistor Failure: Caused by excessive current (e.g., short-circuit in the motor winding).

-

Microcontroller Corruption: Caused by electrical noise or voltage spikes.

-

Communication Errors: Result from faulty RS-485 cables or incorrect wiring.

Diagnostic Tips:

-

Use a multimeter to check the module’s output current (should match the TCU’s command signal).

-

Monitor the module’s status LEDs: A blinking yellow LED indicates normal communication; a solid red LED means a fault (e.g., overcurrent, communication error).

-

Use an oscilloscope to view the output signal waveform (should be a clean DC signal with no noise).

Conclusion

The GE DS3800NEPB1C1C is a critical motor excitation control board in the Mark IV series, designed for reliable operation in harsh industrial environments like turbine control systems. Its precision regulation and seamless integration with Mark IV systems make it an essential component for maintaining stable turbine operation. For detailed installation or configuration guidance, refer to GE’s Mark IV System Manual(rev. 5.0) or contact a GE authorized representative.