Description

Key Technical Specifications

-

Model Number: DS3800NEPD1F1C

-

Manufacturer: GE

-

Bus Protocol: VMEbus Rev. C.1 (8/16/32-bit)

-

I/O Configuration: 16 digital I/O + 8 analog I/O (software-selectable)

-

Data Rate: 1.5 Mbps (RS-485), 19.2 kbps (RS-232)

-

Operating Temperature: -40°C to +85°C (industrial-rated)

-

Isolation: 1500V RMS optocoupler isolation

-

Power Supply: 24V DC ±10% (max 12W draw)

-

Weight: 0.65 kg (1.43 lbs)

-

Certifications: UL AWM Style 20234, CE EN 50155

-

MTBF: >50,000 hours (per MIL-HDBK-217F)

Field Application & Problem Solved

Problem:

Legacy GE Mark IV turbine control systems often face integration challenges with modern field devices (e.g., HART-enabled sensors, Profibus actuators). Outdated VMEbus architectures struggle with real-time data throughput, causing scan time overruns and trip risks.

Solution:

The DS3800NEPD1F1C bridges this gap by:

-

Signal Routing: Directly interfaces with VMEbus CPUs while supporting Modbus RTU, Profibus DP, and ASCII protocols.

-

Signal Conditioning: Filters noise from turbine hall EMI, ensuring clean data transmission to/from sensors (e.g., vibration probes, pressure transmitters).

-

Isolation: Galvanic optocouplers protect sensitive VMEbus logic from voltage spikes during motor startups or lightning surges.

Typical Use Cases:

-

Power Plants: Upgrading analog turbine controls to digital I/O without replacing the entire VMEbus backplane.

-

Refineries: Integrating legacy flow meters with Siemens SIMATIC PLCs via Profibus DP.

-

Paper Mills: Stabilizing communication between ABB ACS880 drives and aging GE Mark IV controllers.

Core Value:

Prevents costly downtime by enabling incremental upgrades. Its ruggedized design survives 24/7 operation in high-vibration turbine enclosures, maintaining <1 ms latency for critical trip signals.

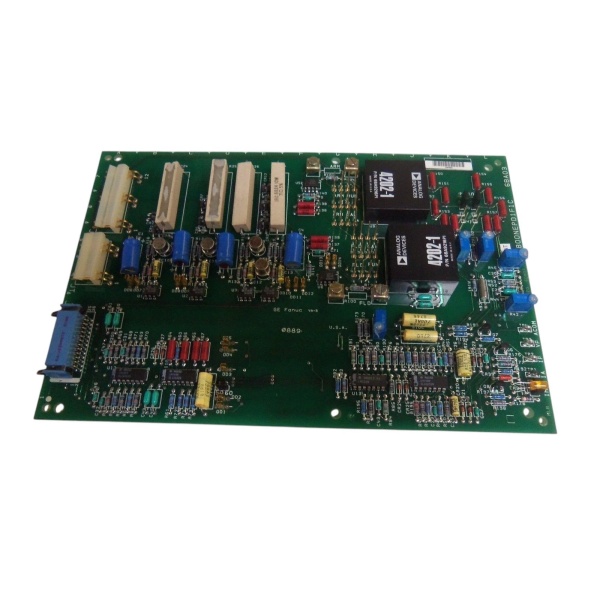

GE DS3800NEPD1F1C

Installation & Maintenance Pitfalls

-

VMEbus Seating:Mistake: Using a non-ESD-safe screwdriver to torque the module.Result: Electrostatic discharge (ESD) fries the VMEbus backplane.Fix: Use a grounded ESD wrist strap and torque screws to 0.8 Nm (7 in-lbs).

-

Grounding:Mistake: Connecting shield ground to the module’s chassis instead of the VMEbus backplane.Result: Ground loops induce 60 Hz noise, corrupting analog inputs.Fix: Bond module chassis to the backplane’s grounding bus using a #10 AWG copper strap.

-

Cable Routing:Mistake: Running unshielded cables parallel to 480V motor feeders.Result: Capacitive coupling causes intermittent RS-485 errors.Fix: Use shielded twisted pair (STP) cables and maintain >30 cm separation from power lines.

-

Configuration:Mistake: Setting analog inputs to 4–20 mA without calibrating the module’s scaling factors.Result: Pressure transmitter reads 0 psi (actual: 100 psi), triggering false turbine trips.Fix: Use GE’s Mark IV Configurator Tool to map input ranges (e.g., 4–20 mA = 0–300 psi).

Technical Deep Dive

The DS3800NEPD1F1C is a dual-channel signal processor designed for GE’s Mark IV turbine control systems. Key components:

-

VMEbus Interface:

-

32-bit data path with 16 address lines for direct CPU memory access.

-

Supports burst transfers (up to 128 bytes) to minimize latency during turbine control loops.

-

-

Signal Conditioning Circuitry:

-

Low-pass RC filters (1 kHz cutoff) on analog inputs to reject high-frequency noise.

-

Schmitt trigger buffers on digital inputs to eliminate contact bounce from mechanical switches.

-

-

Isolation Architecture:

-

Dual-stage optocouplers (6N137) provide 1500V isolation between field and control sides.

-

Isolated DC-DC converter (2W) ensures noise-free power to I/O channels.

-

Failure Modes & Diagnostics:

-

VMEbus CRC Errors: Check for bent pins on the module’s edge connector. Use a multimeter to verify continuity between the module and backplane.

-

Analog Drift: Monitor drift over 24 hours. If >0.5% FS, replace the module’s 2.5V reference IC.

-

Overcurrent Protection: The module includes a 1A self-resetting fuse on each digital output. Persistent tripping indicates shorted loads.